- Roof Load Capacity: Live load & dead load (KN/m²)

- Wind Resistance: Local wind speed (km/h) for stability

- Snow Load (if applicable): Regional snow pressure (kg/m²)

- Seismic Requirements (if applicable): Earthquake zone considerations

Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Steel structure warehouses are high-performance, cost-effective, and fully customizable storage solutions designed for industrial, commercial, agricultural, and logistics applications. They offer flexible layouts tailored to different operational needs and are suitable for a wide range of industries.

Built with premium-grade steel and prefabricated for efficient assembly, these warehouses provide excellent durability, strong weather resistance, and fast installation. The prefabrication process ensures precise construction while reducing labor and construction time on site.

Ideal for global projects, steel warehouses are known for their scalable design, long-term reliability, and low maintenance requirements. From manufacturing plants to distribution centers, our solutions deliver operational safety, sustainable performance, and adaptability for diverse business demands.

On-Site Steel warehouse Installation

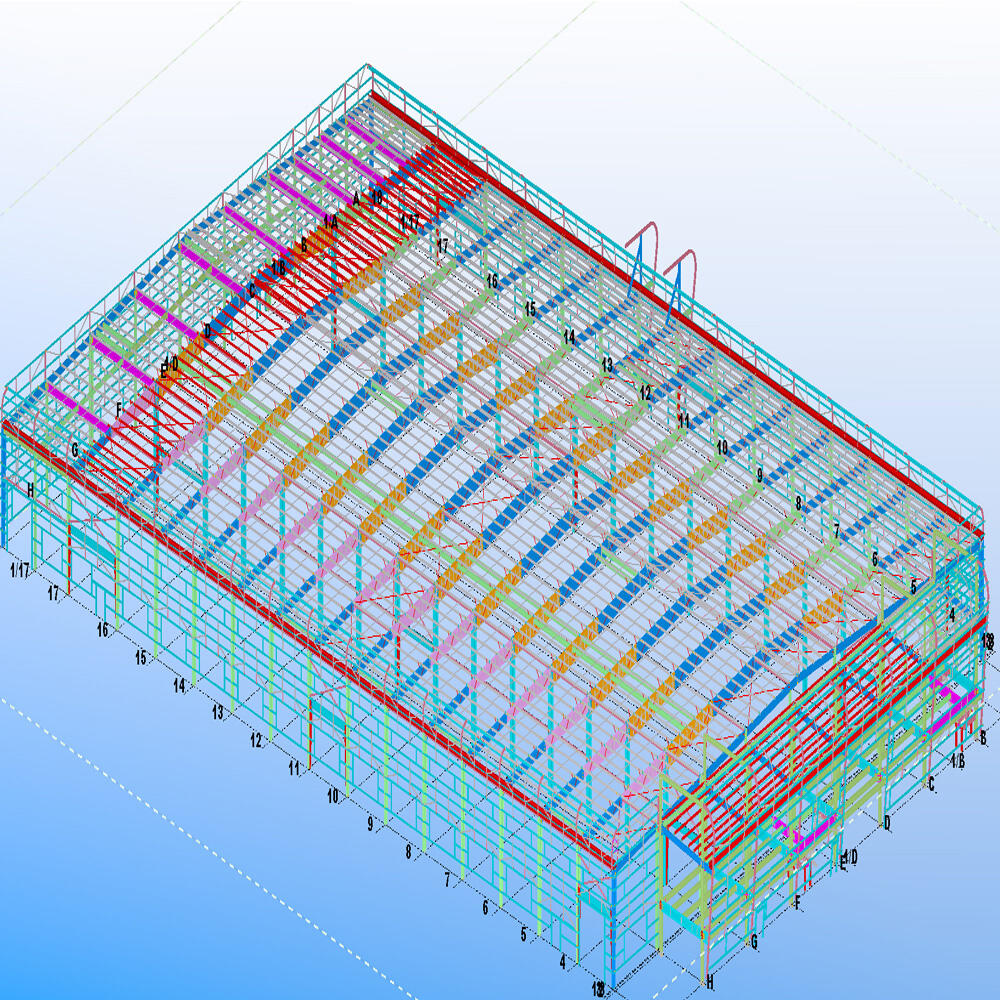

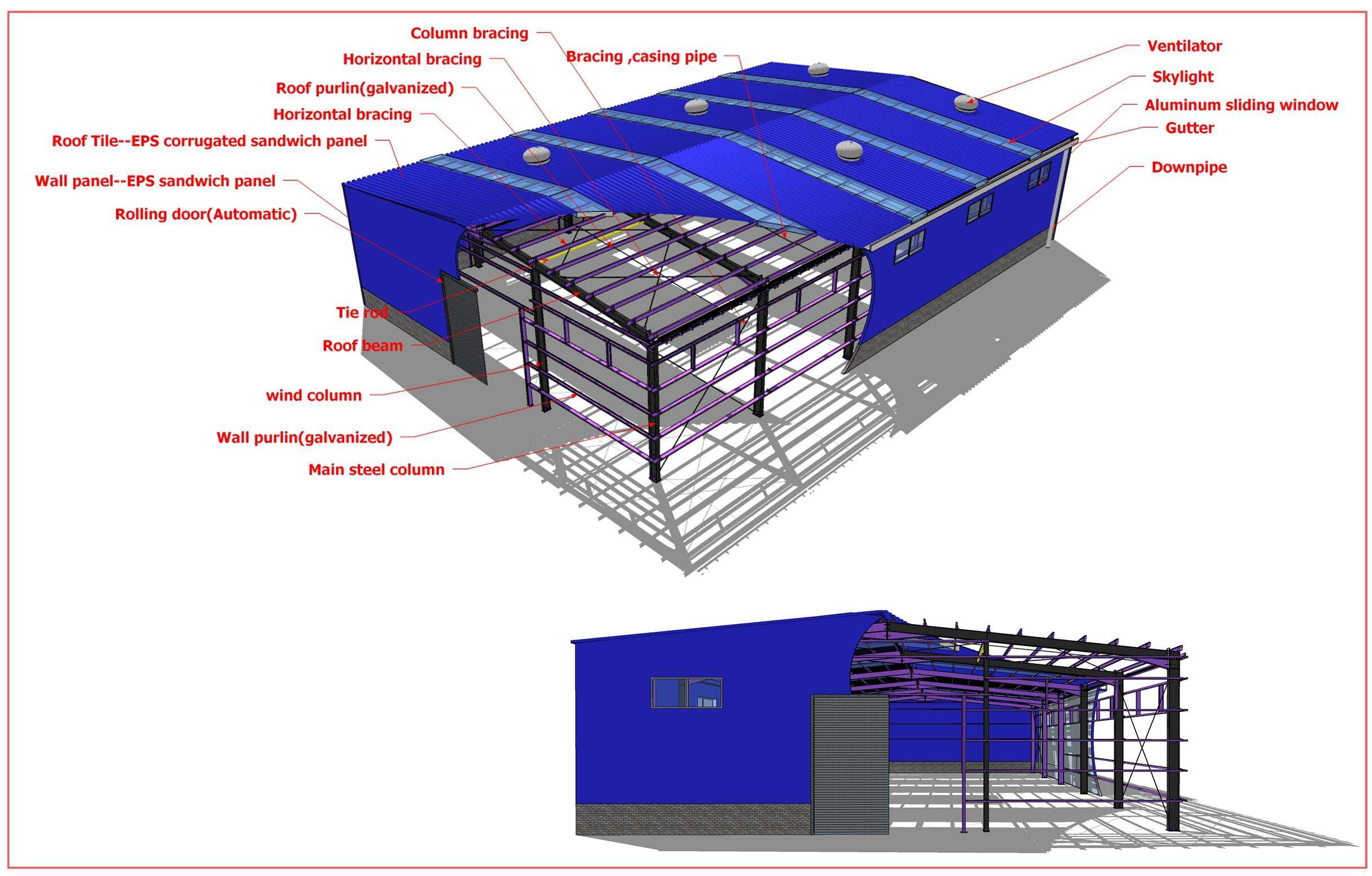

3D Steel Structure Warehouse Model Material Display

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Why Choose a Prefabricated Steel Structure Warehouse?

Steel structure warehouses—especially prefabricated metal warehouse buildings—deliver unmatched durability, cost efficiency, and customization for industrial, commercial, and agricultural storage needs. Engineered for superior performance, these steel warehouses provide long-term reliability with key advantages:

1. Superior Strength & Long-Lasting Durability

Constructed from high-grade steel, our prefab steel warehouses withstand extreme weather, heavy snow loads, and high winds, ensuring decades of reliable use.

2. Fast Installation with Pre-Engineered Components

Factory-made steel warehouse kits allow quick bolt-together assembly, significantly reducing construction time and labor expenses compared to traditional buildings.

3. Fully Customizable Design Options

Tailor your steel warehouse with flexible layouts, sizes, roof styles (like single-slope or gable), and interior configurations to fit your exact storage or operational needs.

4. Cost-Effective & Low-Maintenance Solution

Steel warehouses offer lower upfront construction costs, minimal upkeep, and a longer lifespan than conventional brick or wood structures—maximizing ROI.

5. Fireproof & Pest-Resistant Construction

Unlike wood, steel is non-combustible and immune to termites, rodents, and mold, providing a safer, more secure storage environment.

Steel warehouse application

Our prefabricated steel warehouses are widely used in various industries, offering reliable and flexible space solutions for diverse needs:

Ideal for grain storage, feedstock shelters, and farm equipment housing in rural or agribusiness environments.

Provides efficient space for machinery, production lines, and raw material storage with clear-span layouts.

Perfect for distribution hubs, inventory management, and packaging operations requiring large open interiors.

Used for vehicle repair shops, machinery service stations, and custom fabrication workshops.

Suitable for wholesale storage, cold storage applications, and even retail distribution centers.

Steel Warehouse Fabrication Process:

Custom Steel Warehouse Design Parameters | Expert Guidelines

Planning your steel structure warehouse? Here are the key design specifications we’ll need to engineer a solution tailored to your project:

1. Structural Load Requirements

2. Door & Window Configuration

3. Crane Specifications (For Industrial Warehouses)

4. Building Dimensions & Layout

Unsure About Your Needs?

If this is your first project, our engineers will analyze your local climate, usage, and budget to recommend the optimal design—ensuring safety, efficiency, and cost-effectiveness.

Contact Us to Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691