Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Workshop

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

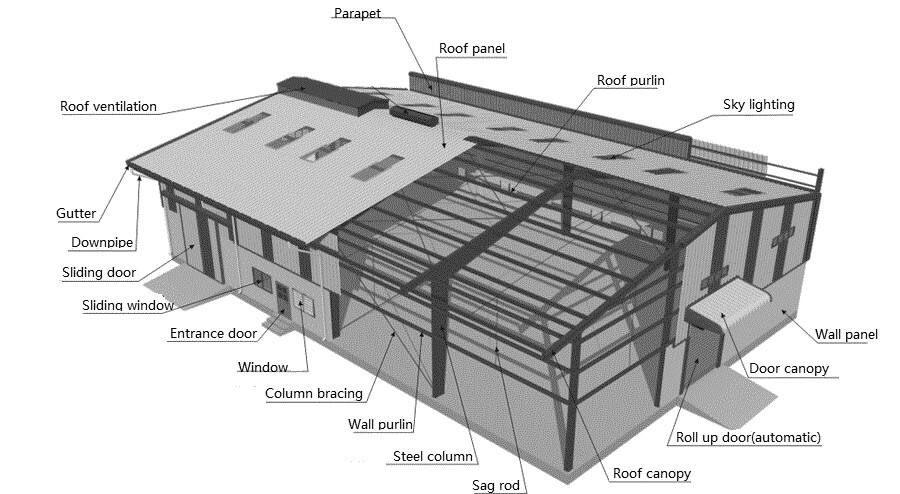

A steel workshop is a durable, fully customizable facility designed for industrial manufacturing and processing. Built primarily with steel frames, it provides a safe, strong, and long-lasting structure ideal for housing machinery and tools used in production.

These steel structure buildings can be tailored to meet specific project needs—whether in terms of size, layout, or integrated features like overhead cranes, ventilation, and thermal insulation. A well-designed steel workshop improves workflow efficiency and supports high productivity in a variety of industrial applications.

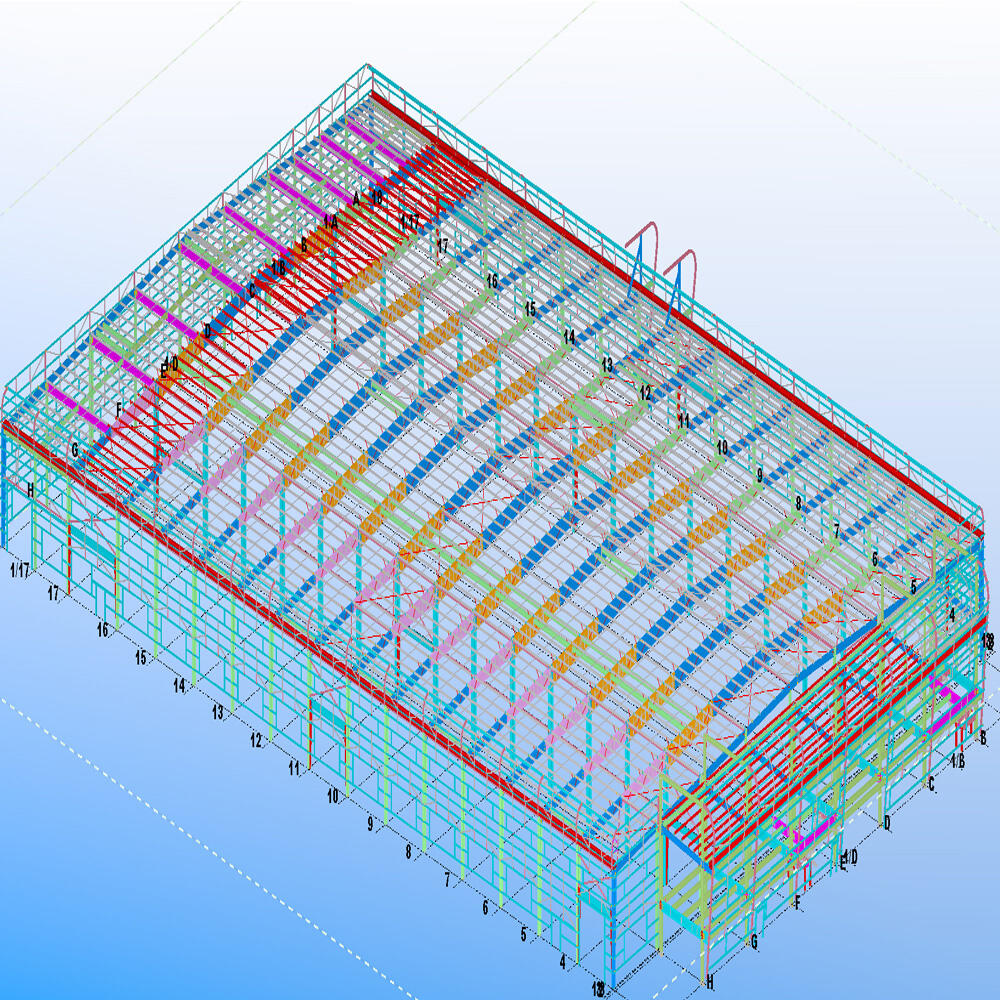

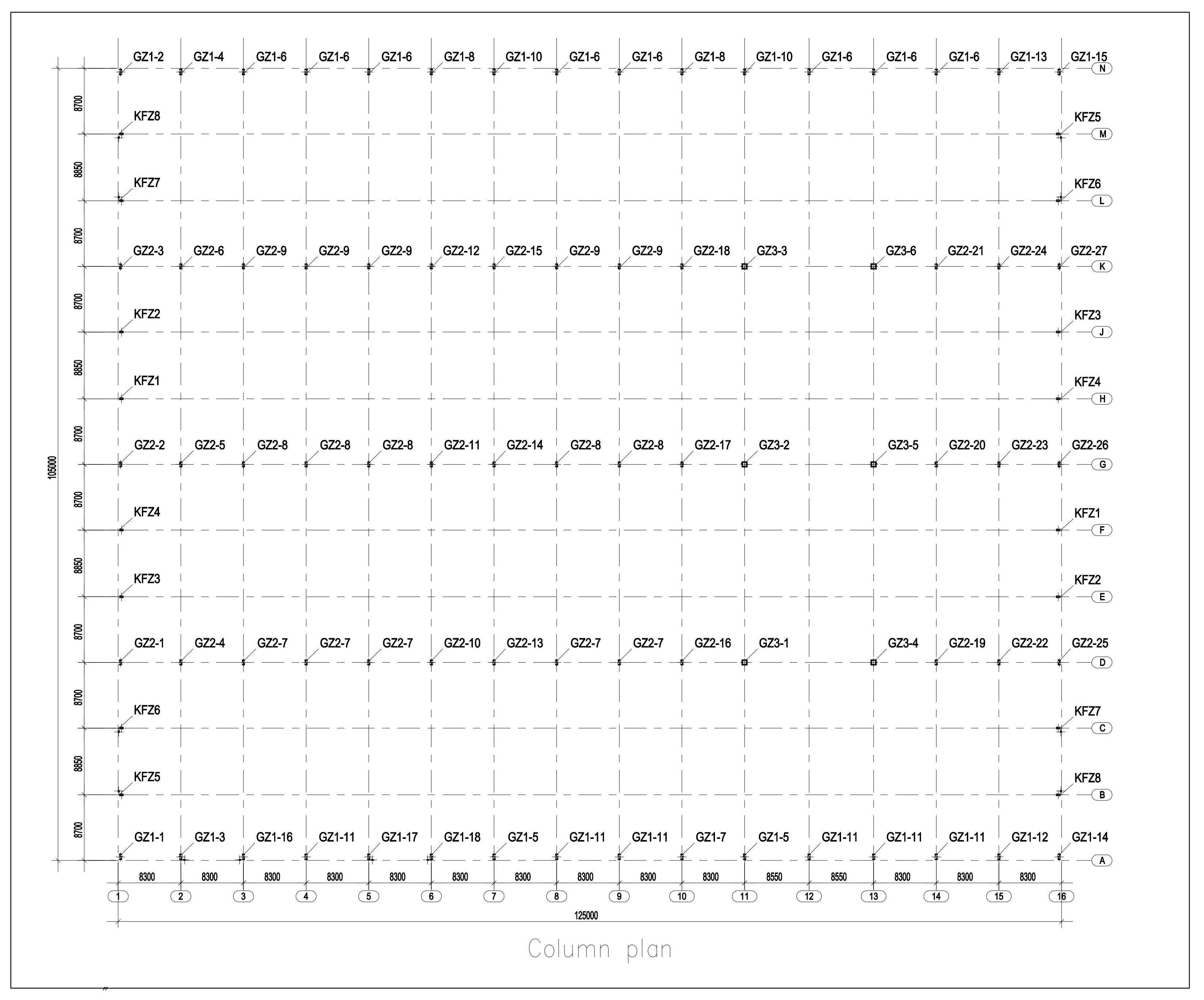

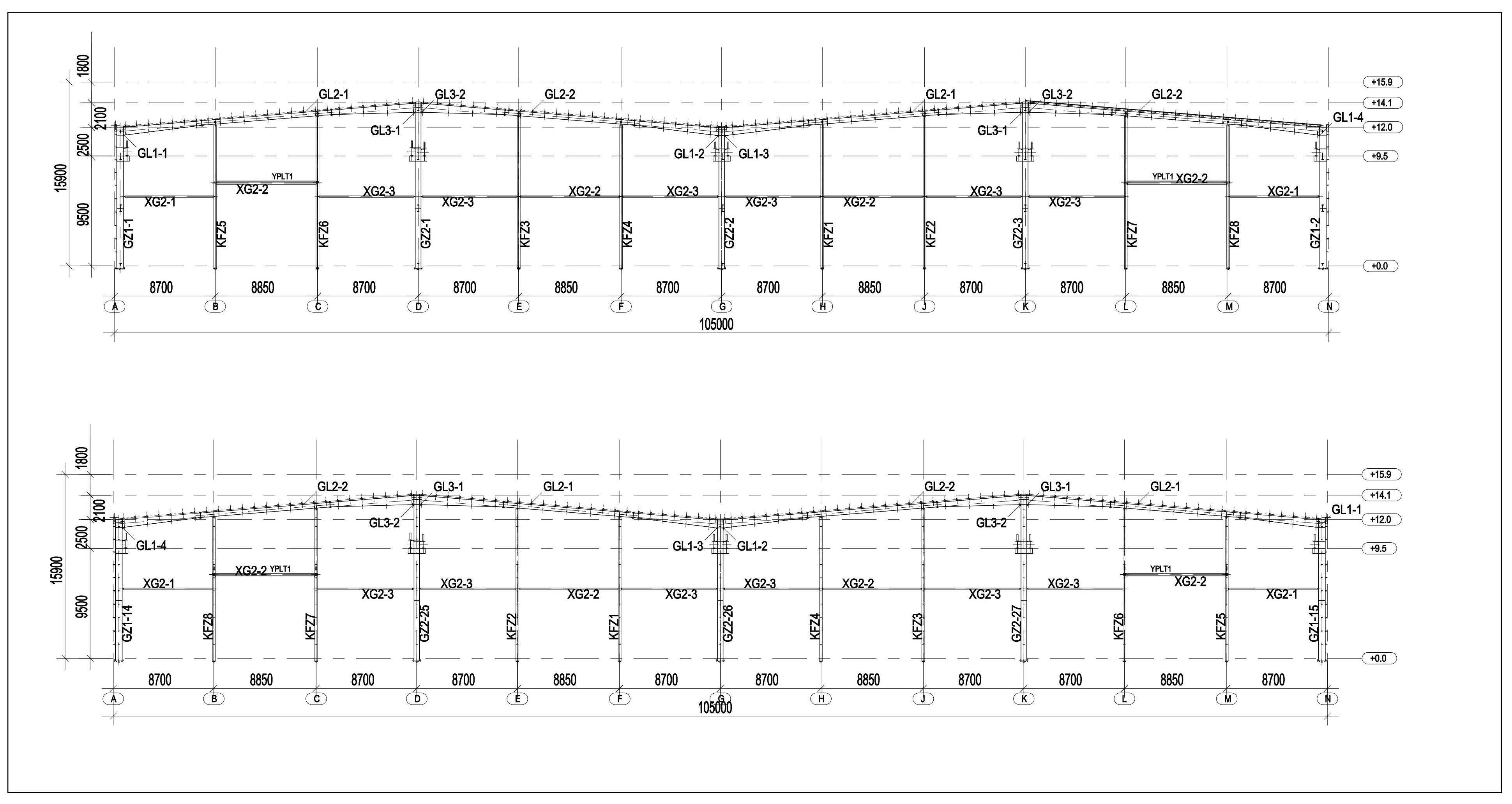

Steel workshop layout

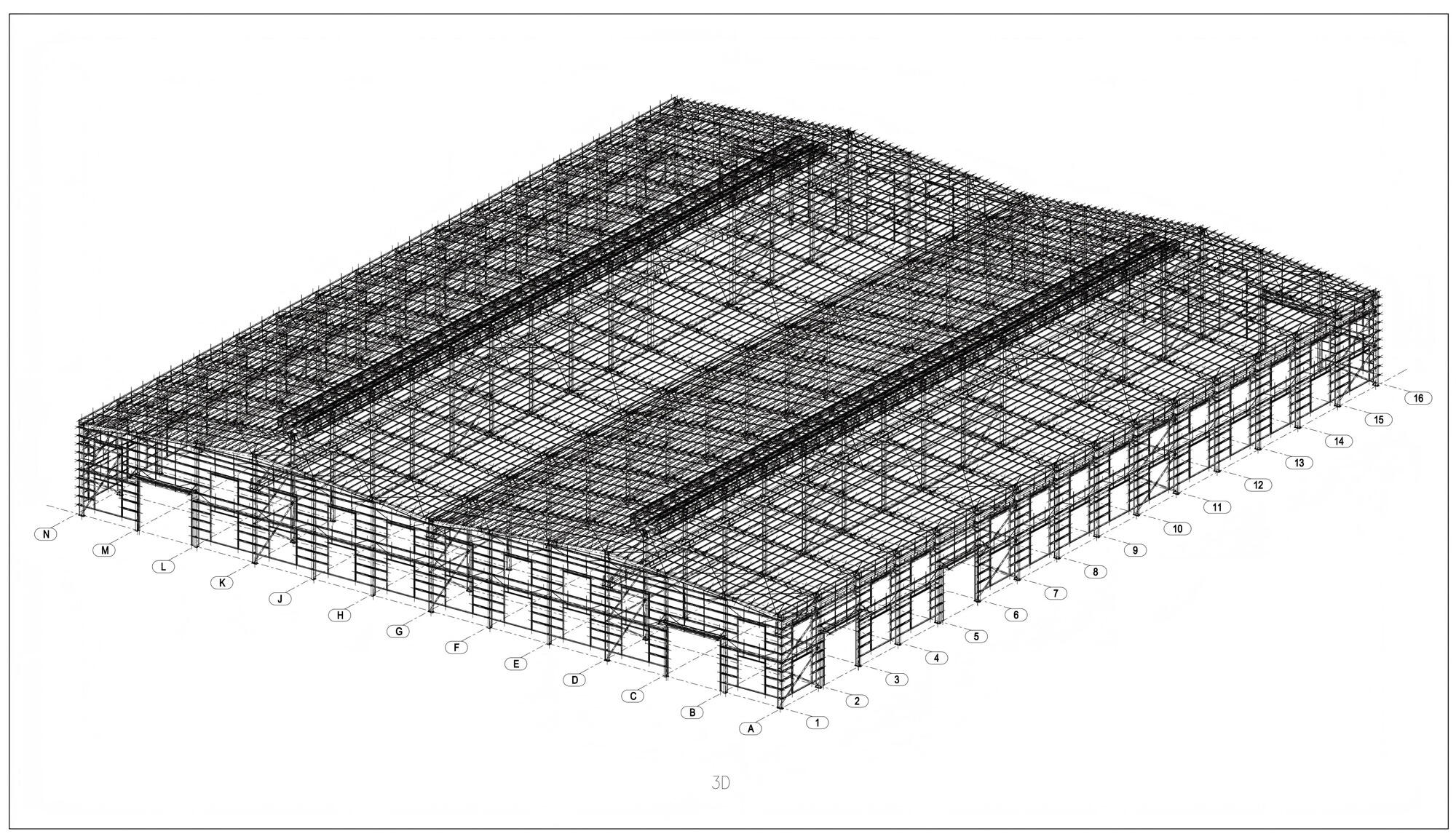

On-Site Steel Frame Installation

Fast Installation. Strong Performance. Real Projects.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Steel workshop application

Why steel structure workshop is a popular choice in various industries?

Sturdy and long-lasting:

Steel is a durable material that can withstand extreme weather conditions, seismic activity, and heavy loads.

Cost-effective:

Steel structures require less maintenance and steel structures can be prefabricated off-site, which can reduce the construction time and labor costs.

Versatility:

Steel structures offer flexible design, they can be easily customized to meet specific industrial requirements and accommodate various activities.

Speed of Construction:

Steel structures can be erected quickly, which enables faster project completion times.

Sustainability:

Steel is a recyclable material, making it an environmentally friendly choice. Reducing waste, and conserving natural resources.

Safety:

Steel structures undergo rigorous testing and quality control, ensuring compliance with safety standards. Steel is also fire-resistant, providing added safety in case of fire incidents.

Steel Workshop Fabrication Process:

Start Your Project

Ready to build a durable and cost-effective prefabricated steel workshop? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691