Steel Grade: Q235B/Q355B (GB standard)

Application: Steel workshop

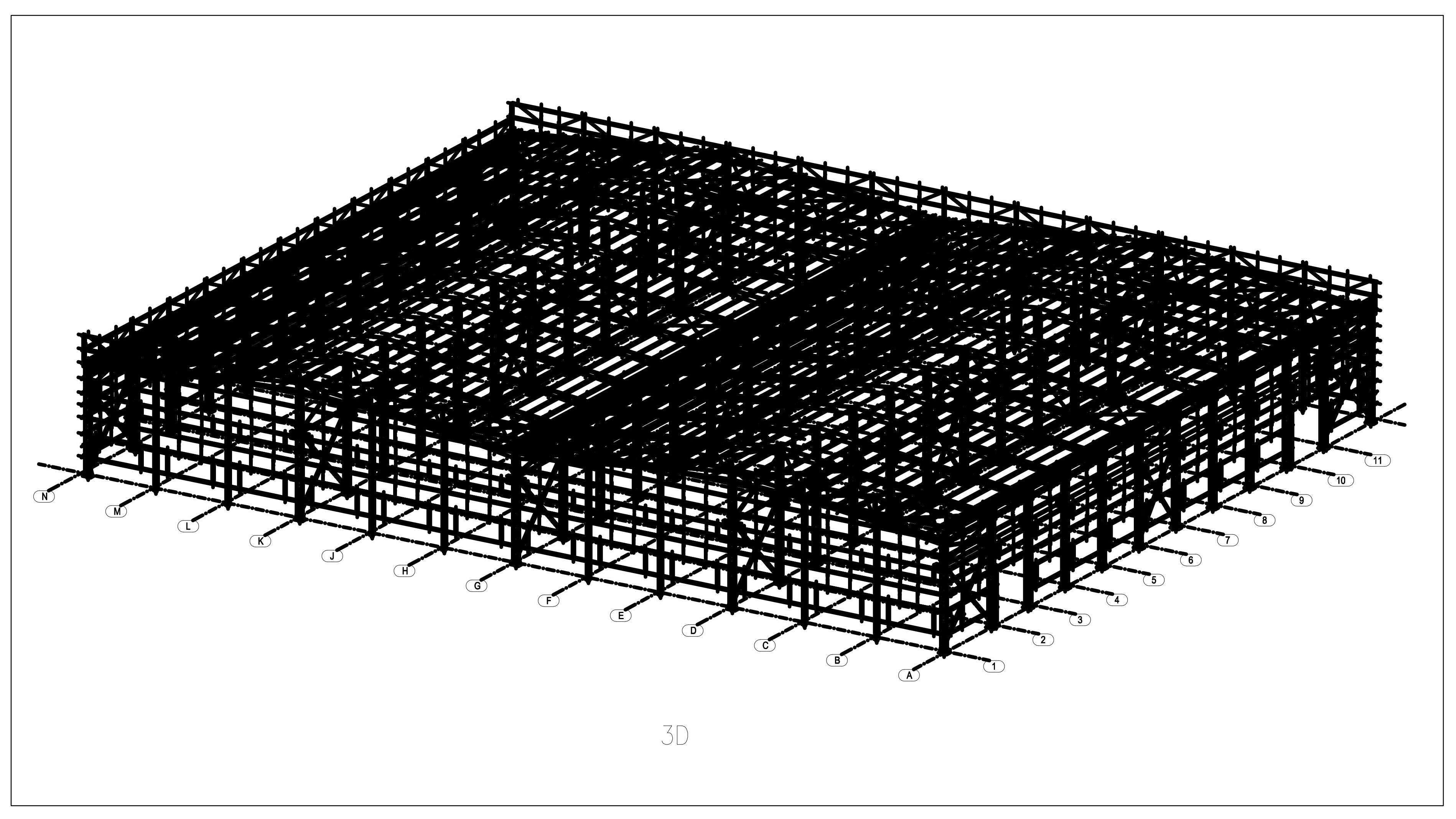

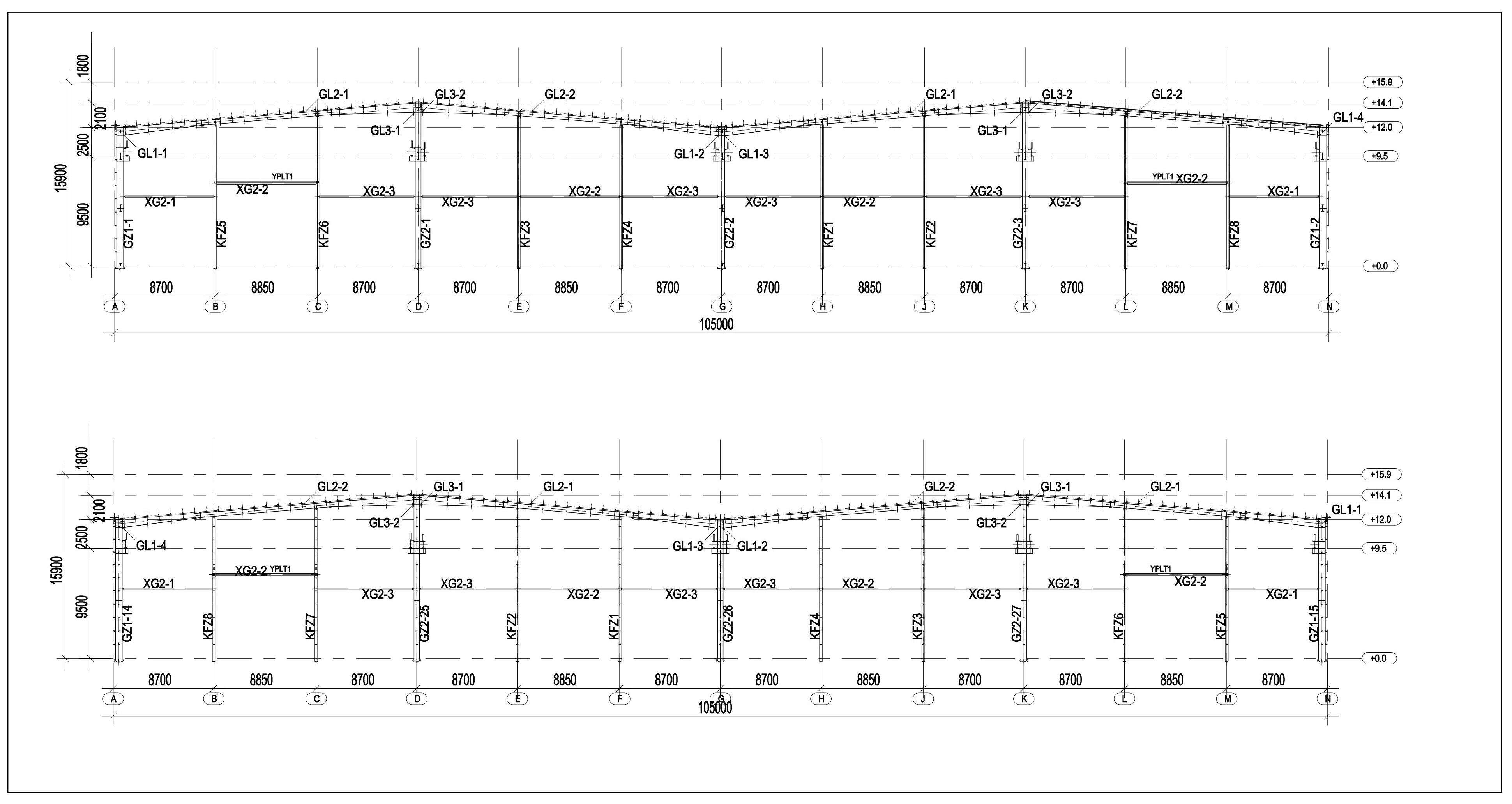

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

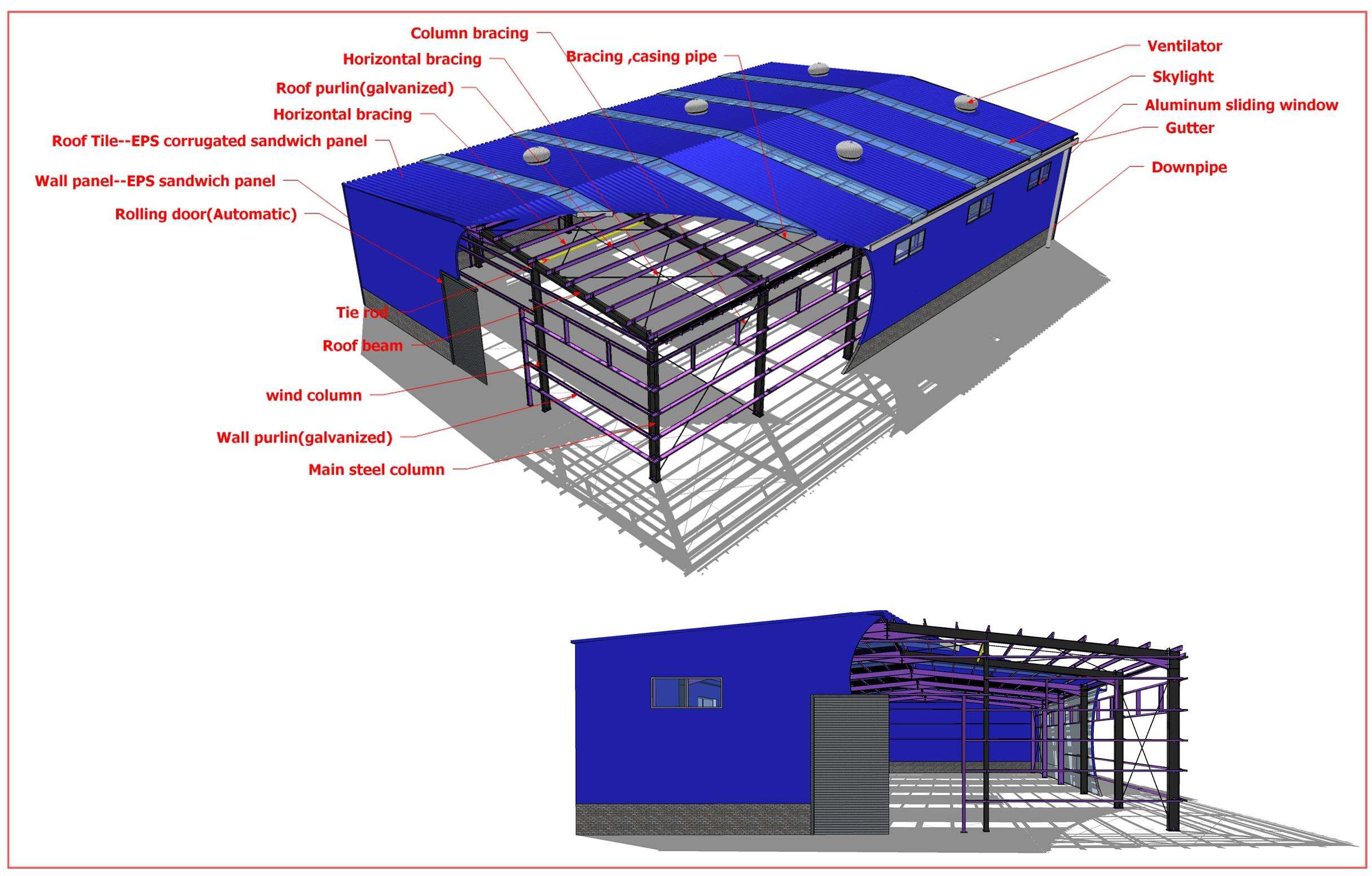

Our Portal Frame Steel Workshop is a high-performance solution designed for a wide range of industrial facilities, including manufacturing plants, logistics centers, automotive workshops, and food processing factories. Built with high-strength structural steel and a wide clear-span design, it offers an open and flexible interior layout—perfect for machinery installation, production lines, or large-volume storage.

The entire structure can be fully customized based on your operational needs. Optional features include overhead crane beams, thermal insulation, roof ventilation, skylights, and other functional upgrades. This versatility makes our steel workshop building ideal for diverse climates and industries around the world.

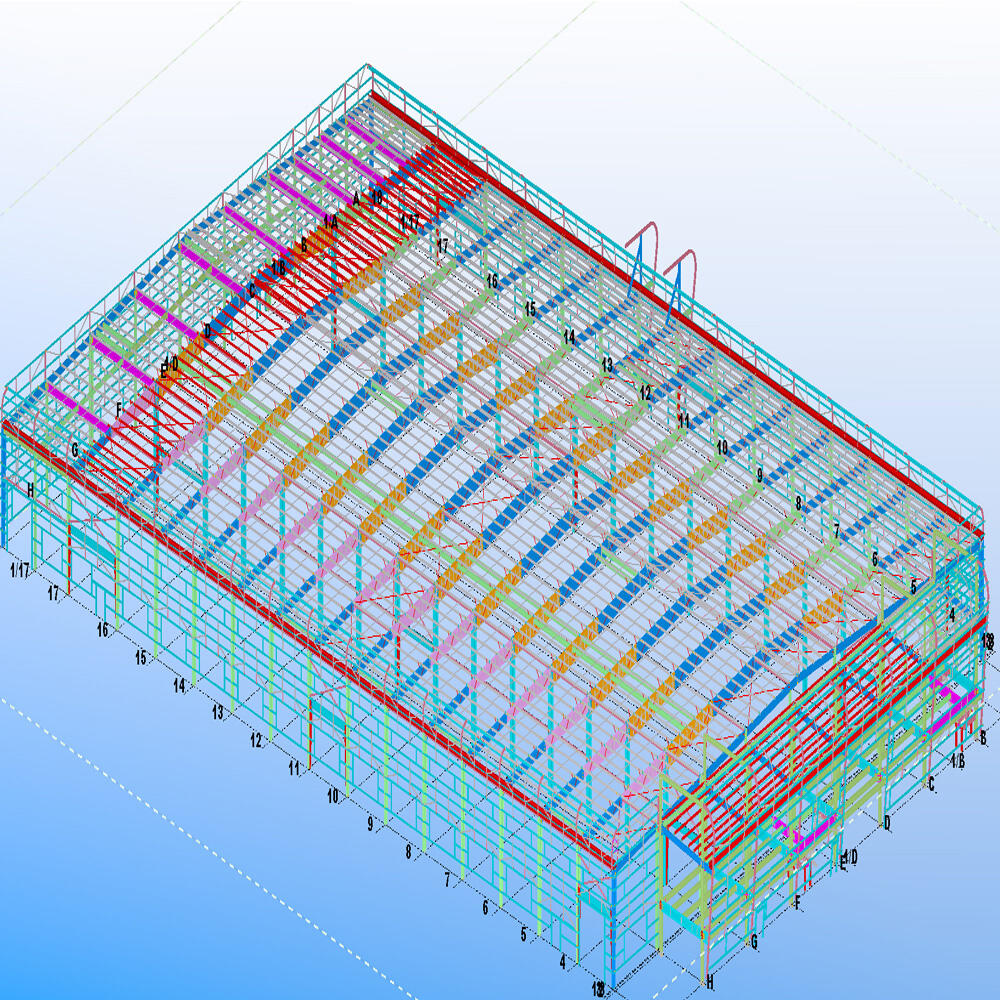

Steel workshop layout

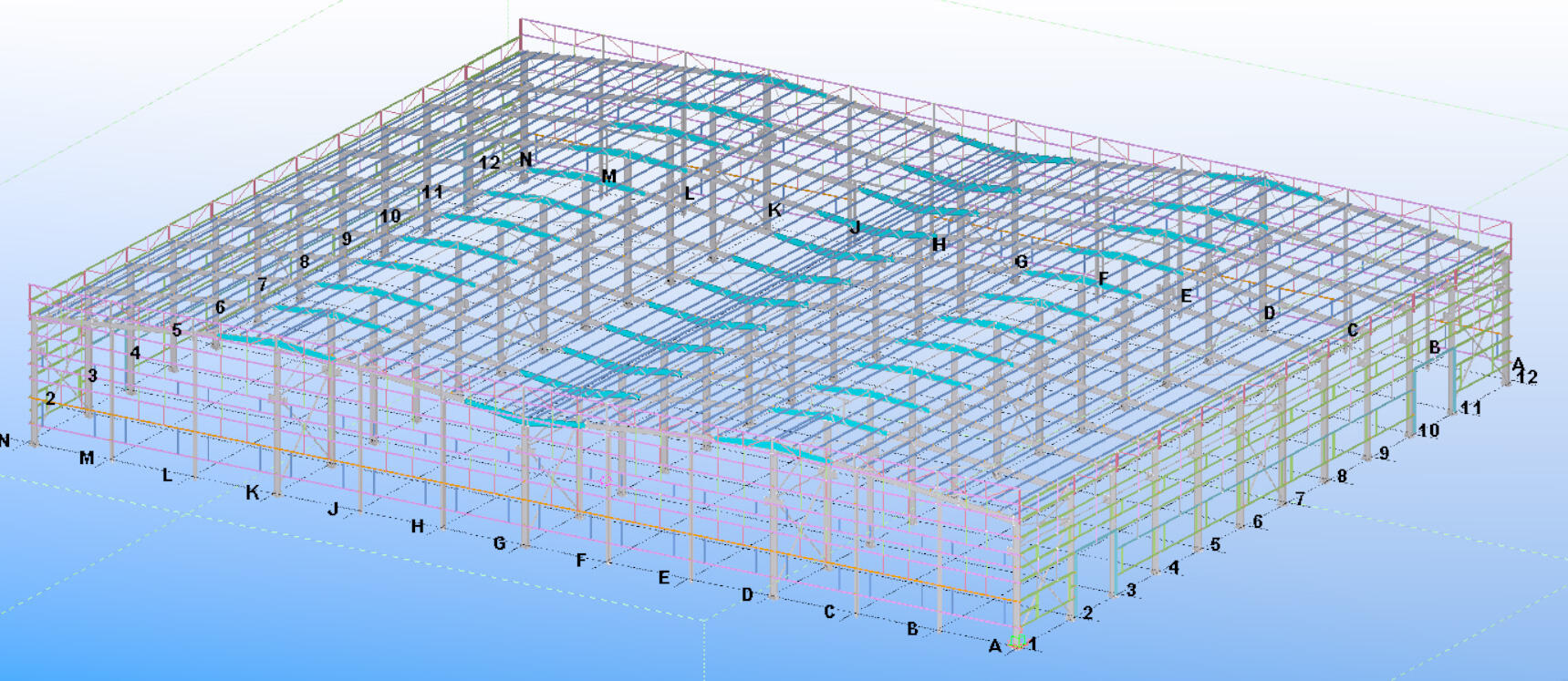

On-Site Steel Frame Installation

Fast Installation. Strong Performance. Real Projects.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Steel Workshop Advantages

1.Durable and Long-Lasting

Made from high-strength steel, our workshop buildings offer excellent resistance to corrosion, weather, and wear, ensuring decades of reliable use.

2.Fast and Efficient Construction

All components are prefabricated in the factory, allowing for quick on-site assembly and reduced labor costs.

3.Flexible Design Options

Clear-span structures provide open interior space without columns, easily adaptable for machinery layout, storage, or production lines.

4.Cost-Effective Solution

Lower material and maintenance costs compared to traditional concrete or brick buildings, offering excellent value over the long term.

5.Customizable for Any Industry

Available with optional features like insulation, skylights, ventilation, crane support, and more—tailored to your specific industrial needs.

6.Environmentally Friendly

Steel is 100% recyclable and creates less construction waste, supporting sustainable building practices.

Industrial Steel Workshop Applications

Our industrial and commercial steel workshops are engineered to deliver durable, customizable, and cost-effective building solutions. These prefabricated steel structures are ideal for factories, warehouses, logistics centers, and more—designed for long-term performance and quick installation.

✔ Manufacturing Plants: Robust steel frames support heavy machinery and production lines.

✔ Warehousing & Logistics: Wide-span designs maximize storage space and loading efficiency.

✔ Agricultural Storage: Weather-resistant steel protects crops, equipment, and livestock.

✔ Aviation & Automotive: Large clear-span workshops accommodate aircraft, vehicles, and assembly lines.

✔ Commercial Workshops: Customizable layouts for repair shops, showrooms, and commercial spaces.

Steel Workshop Fabrication Process:

Start Your Steel Workshop Project Today

Looking to build a durable, cost-effective prefabricated steel workshop? Contact our expert team for a customized solution tailored to your needs. From design and manufacturing to on-site installation and after-sales support—we’re here to help every step of the way.

E-mail: [email protected]

Phone: +86-13535848691