Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

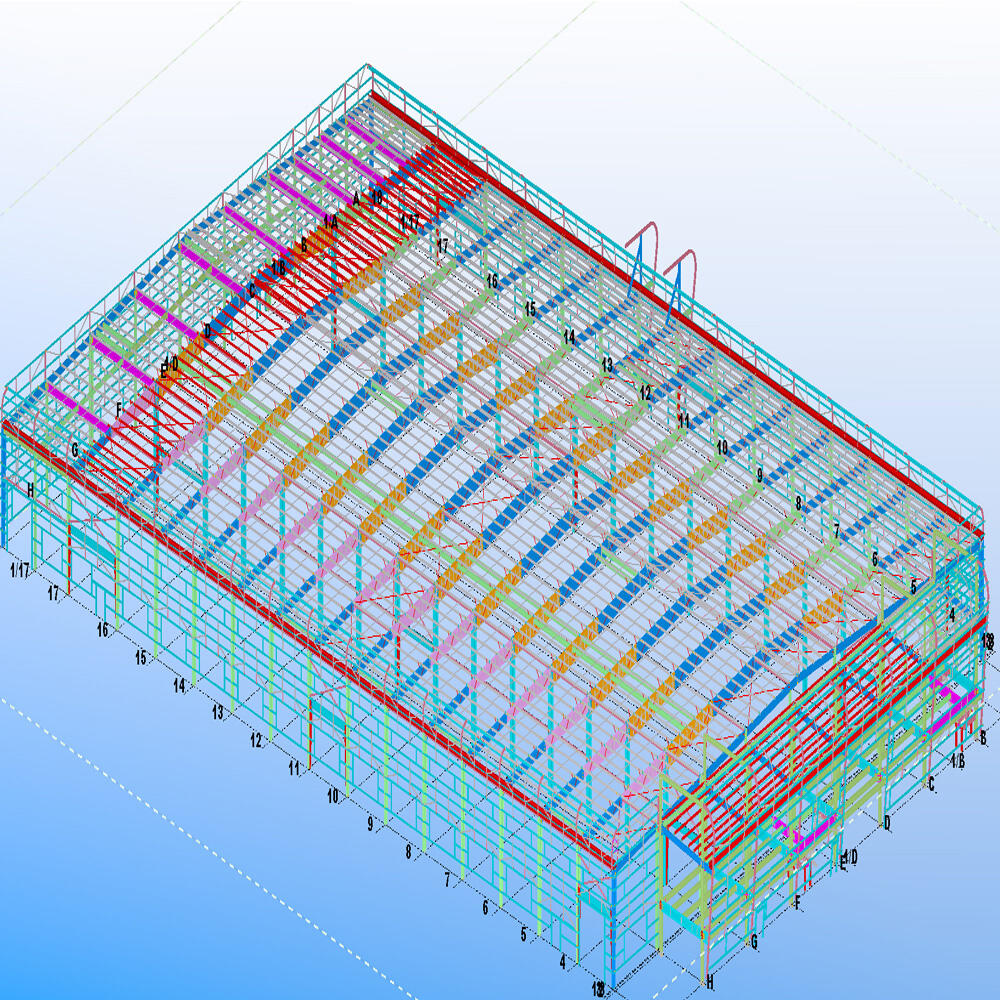

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Steel structures are widely used for their strength, durability, and versatility. They are ideal for heavy industrial buildings like workshops and warehouses, capable of supporting heavy loads and harsh conditions.

Steel is also popular in high-rise buildings due to its ability to enable taller structures with fewer columns, creating flexible interior spaces.

Additionally, steel frames are commonly used in equipment support systems such as platforms and frameworks, as well as infrastructure projects like bridges and towers that require long-span strength.

Steel construction is also favored in airport terminals, industrial plants, and storage shed, offering reliable performance and design flexibility.

Overall, the durability and adaptability of steel make it a preferred material for many modern construction projects.

On-Site Steel warehouse Installation

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

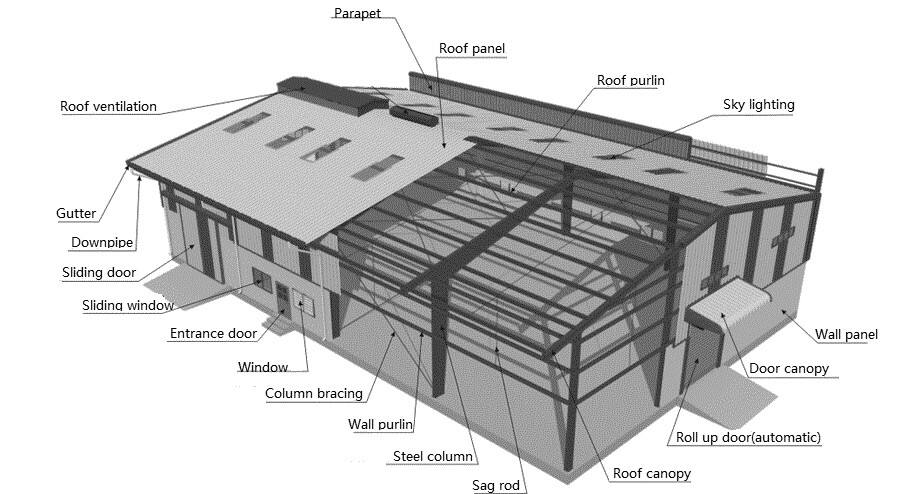

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Steel structure warehouse advantages

1. Design architectural drawings for you for free

We offer the service of providing architectural drawings at no additional cost, ensuring that the design meets your specific requirements.

2. Strong bearing capacity

The steel structure building is designed to withstand strong winds, earthquakes, and heavy snow loads, ensuring its stability and durability even in harsh weather conditions.

3. Fast and flexible assembly

The steel structure allows for quick and flexible assembly, saving time and providing convenience during the construction process.

4. High-cost performance

The quick and easy installation process significantly reduces construction time and costs. Moreover, the overall structure is easy to maintain and has a lifespan of over 50 years, providing long-term cost savings.

5. Safety

The steel structure building is designed with safety in mind. It features fireproof walls and complies with national fire protection ratings, ensuring the protection of the occupants and their belongings.

6. Heat insulation, sound insulation, waterproof, and fireproof

The steel structure provides excellent insulation properties, keeping the interior temperature stable and reducing energy consumption. The structure is waterproof and fireproof, providing added protection.

Steel Warehouse vs. Traditional Building

Feature |

Steel Warehouse |

Traditional Building |

Durability |

High – corrosion & pest resistant |

Medium – prone to decay |

Construction Time |

Short – prefabricated |

Long – on-site processing |

Cost Efficiency |

Lower total cost |

Higher labor and material |

Environmental Impact |

Recyclable, low waste |

More resource-intensive |

Fire Resistance |

Yes – fireproof materials |

Varies – not always resistant |

Applications of Steel Warehouse Buildings

Steel structure warehouses are widely used across various sectors due to their strength, durability, and fast installation. These versatile buildings are ideal for both domestic and international markets, offering long-term performance with low maintenance.

Common applications include:

Steel Warehouse Fabrication Process:

Contact Us to Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691