Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

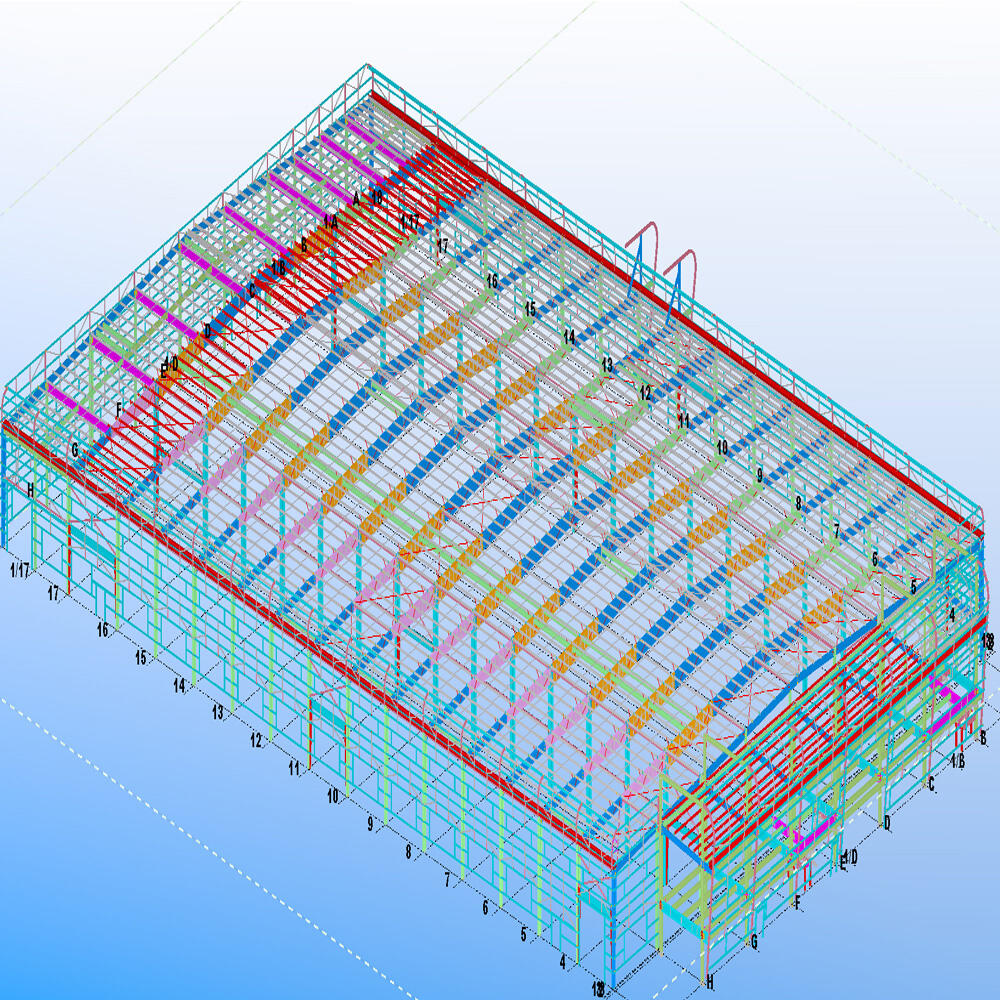

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

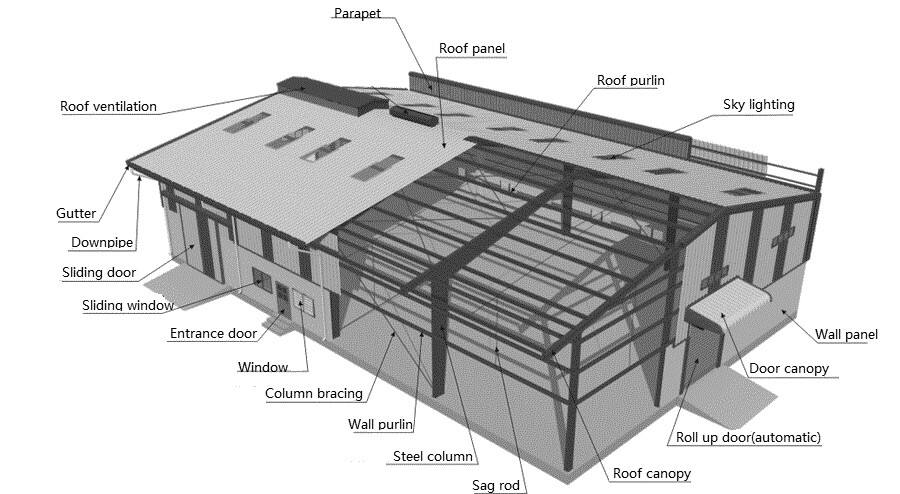

A steel structure warehouse is a durable and reliable storage building constructed with steel load-bearing components such as steel columns, beams, foundations, roof trusses, and bracing systems. These structural elements ensure long-term strength and stability, making the building suitable for heavy-duty storage applications.

Depending on project requirements, the warehouse walls can be built using steel sheets, steel sandwich panels, or concrete blocks. This flexibility allows for customized solutions that meet different insulation, cost, and durability needs.

This type of steel warehouse is widely used for storing construction materials. It offers a spacious, open layout without a crane system, making it ideal for organizing and accessing large volumes of goods efficiently. Its simple structure and easy assembly also contribute to faster installation and lower overall construction costs.

On-Site Steel warehouse Installation

Steel Warehouse Wall System Options

Steel structure warehouses offer flexible wall system configurations to meet different project needs. Common wall system types include:

1)Full Metal Wall System

Constructed with C purlins and clad with steel sheets or insulated sandwich panels, this system provides a lightweight and fast-installing solution, ideal for most standard steel warehouses.

2)Combination Wall System

A hybrid solution using C purlins with steel sheet or sandwich panels on the upper section, and brick or concrete block walls on the lower section. This option offers improved durability and thermal insulation near ground level.

3)Full Masonry Wall System

Built entirely with brick or concrete walls, this system delivers excellent sound insulation, security, and impact resistance, suitable for warehouses requiring high structural protection.

Why Most Clients Choose the Combination Wall System

Approximately 80% of customers prefer the combination wall system, which uses brick walls for the lower section and steel sheet panels or sandwich panels for the upper section. This hybrid design not only offers enhanced structural strength but also provides a reliable waterproofing solution.

There is no need to worry about water leakage at the junction between the brick wall and the steel panel. With the use of proper wall flashing and edge trim, this connection can be effectively sealed, ensuring long-term performance and protection from rain and moisture.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Applications of Steel Warehouse Buildings

Steel structure warehouses are widely used across various sectors due to their strength, durability, and fast installation. These versatile buildings are ideal for both domestic and international markets, offering long-term performance with low maintenance.

Common applications include:

Why Choose Steel Structure Warehouses

Perfect for warehouses, factories, offices, gyms, and hangars—suitable for both single-span and multi-story buildings.

Factory-prefabricated components make on-site assembly quick and reduce construction time.

Steel structures are durable, weather-resistant, and easy to maintain.

Clean lines, color panel options, and customizable wall materials for a modern and practical look.

Lightweight steel lowers foundation costs and speeds up completion—more economical than concrete.

Steel Warehouse vs. Traditional Building

Feature |

Steel Warehouse |

Traditional Building |

Durability |

High – corrosion & pest resistant |

Medium – prone to decay |

Construction Time |

Short – prefabricated |

Long – on-site processing |

Cost Efficiency |

Lower total cost |

Higher labor and material |

Environmental Impact |

Recyclable, low waste |

More resource-intensive |

Fire Resistance |

Yes – fireproof materials |

Varies – not always resistant |

Steel Warehouse Fabrication Process:

Contact Us to Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691