Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Hot-Dip Galvanized Steel Structure Chicken House is a reliable and long-lasting solution for modern poultry farming. Built with premium hot-dip galvanized steel, the structure delivers superior resistance to rust, corrosion, and harsh environmental conditions.

Ideal for both broiler and layer farming, this structure provides a clean, safe, and well-ventilated environment to support healthy poultry growth and high productivity.

Easy to install and customize, it’s suitable for commercial poultry farms of all sizes. We offer flexible designs tailored to your layout, capacity, and local farming needs.

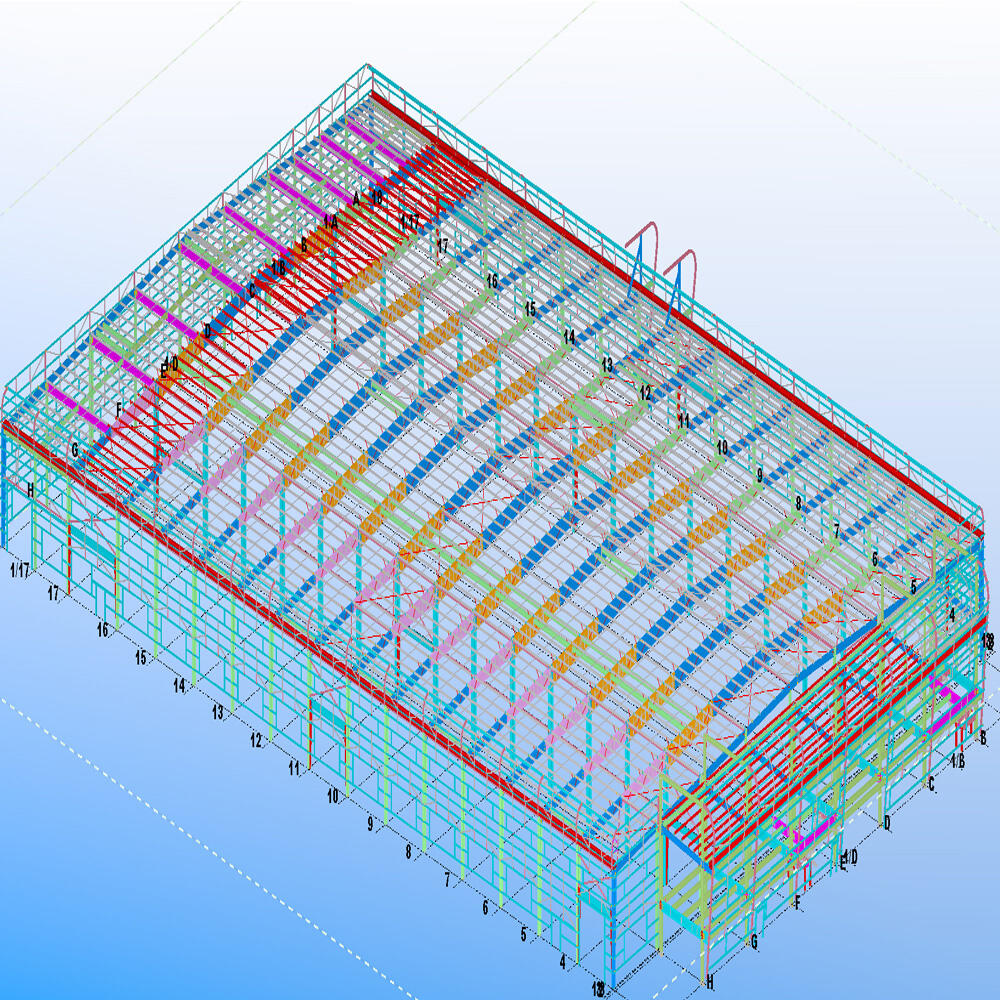

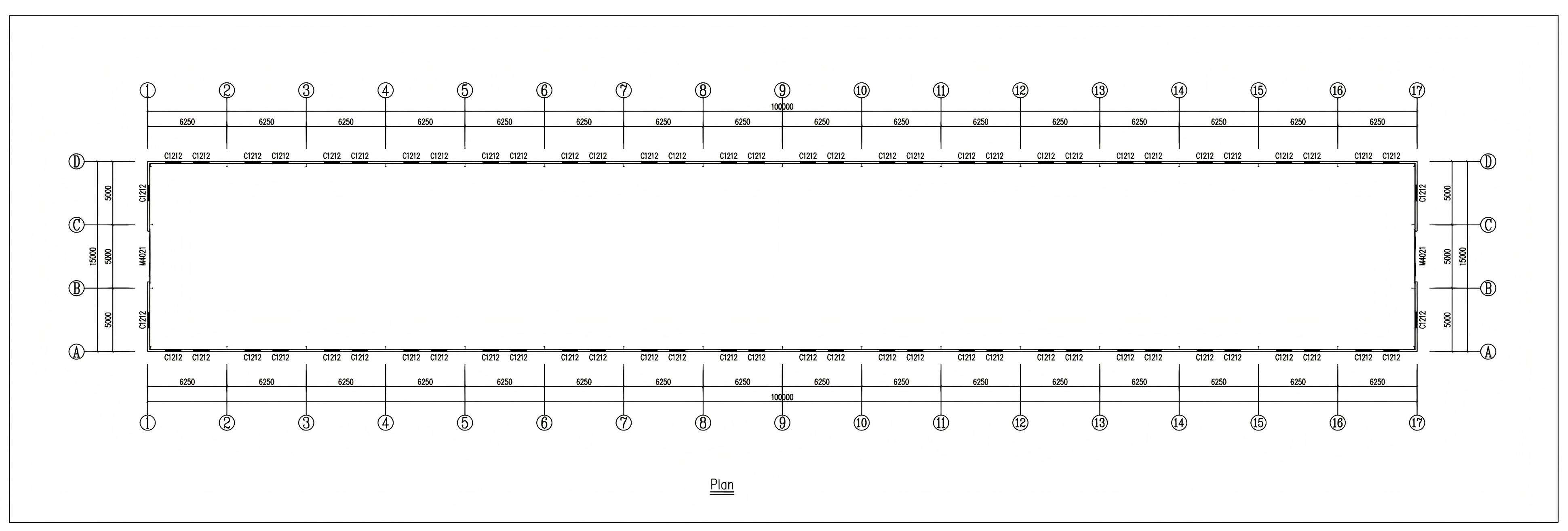

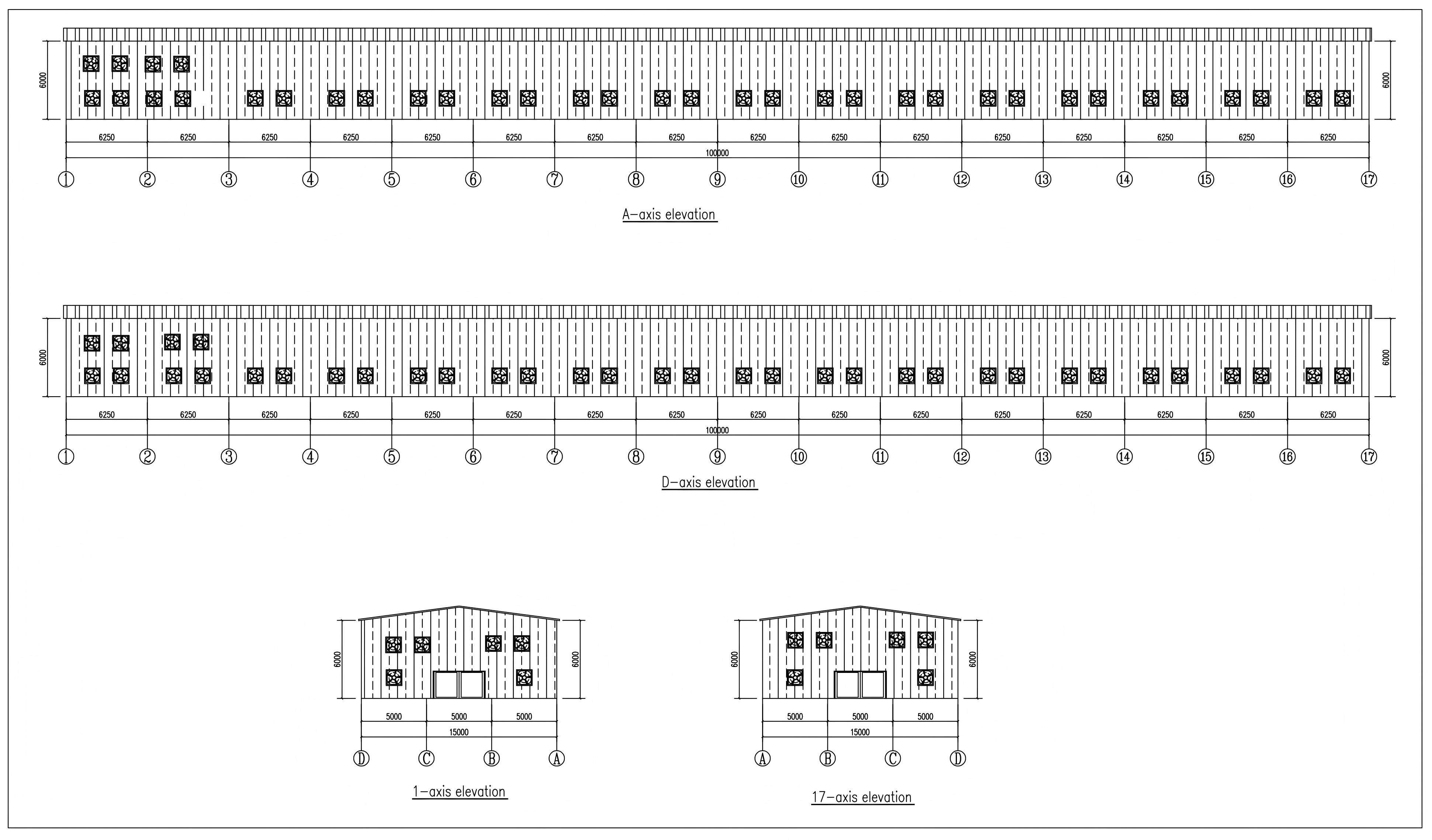

Steel Chicken house layout

Completed Steel Poultry House Projects

Specifications for Steel Structure Chicken House

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Wall Ventilator/Fan |

1200mmx1200mm (Galvanized) |

||

Why Poultry Farmers Choose Our Galvanized Steel Chicken Houses

Our hot-dip galvanized steel structures feature a zinc coating over 100μm thick, delivering over 50 years of lifespan. They outperform traditional wooden or plastic poultry houses by over 400% in salt spray tests. Each structure is engineered to withstand up to 150km/h wind speeds and snow loads of 1.5kN/m², making it ideal for coastal or cold regions.

The interior design includes smooth, antimicrobial surfaces that reduce bacteria and pathogen buildup by 70% compared to conventional materials. A patented ventilation system maintains consistent airflow of 0.8–1.2m/s, ensuring fresh air and temperature stability year-round.

Our galvanized poultry houses are pre-engineered for modern farming technology. Pre-installed mounting points support automated climate control systems. The roof pitch (15°–30°) improves natural ventilation and is compatible with solar panels. Clear-span designs up to 36 meters maximize internal space without columns.

Thanks to pre-drilled and modular components, assembly is up to 60% faster than traditional builds. With no need for repainting or structural repairs, lifetime costs are reduced by up to 40% compared to wood-framed poultry buildings.

Common Applications of Poultry Farm Structures

1. Broiler Chicken Farming

Used for raising chickens for meat production. Requires well-ventilated, fast-growing environments with climate control.

2. Layer Chicken Farming

Designed for hens that produce eggs. Often requires tiered cages or floor systems with lighting, nesting boxes, and feeding automation.

3. Breeder Poultry House

Used for maintaining breeding flocks. These structures must control mating ratios, lighting, temperature, and space per bird.

4. Duck, Turkey & Quail Farming

We offer customized steel buildings for raising ducks, turkeys, or quails, supporting diversified poultry businesses.

FAQ

Q1. Can your steel chicken house support automated systems?

Yes. It supports automatic feeders, drinkers, fans, lighting, and climate control. The roof design also supports solar panel installation.

Q2. What type of foundation is needed?

A concrete strip or concrete slab foundation is recommended. We provide foundation drawings with anchor bolt positions for easy on-site setup.

Q3. How long does delivery and installation take?

Production takes 25–30 days, with installation in 2–4 weeks, depending on project size. We provide full instructions and remote support.

Q4. How long does a galvanized chicken house last?

Up to 50 years with proper maintenance. The zinc coating prevents rust and extends the life of the steel frame in all climates.

Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691