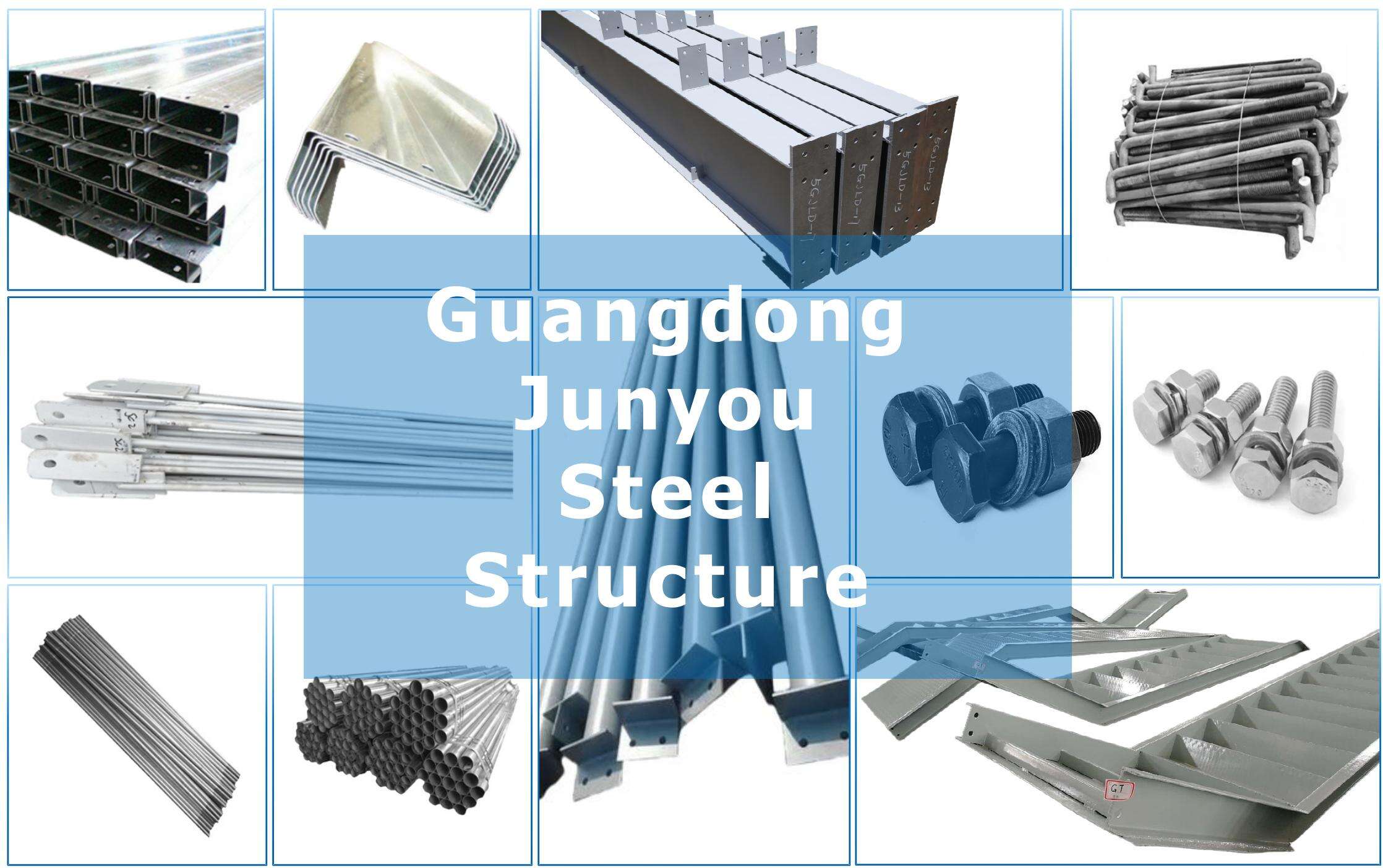

Steel Grade : Q235B/Q355B (GB standard)

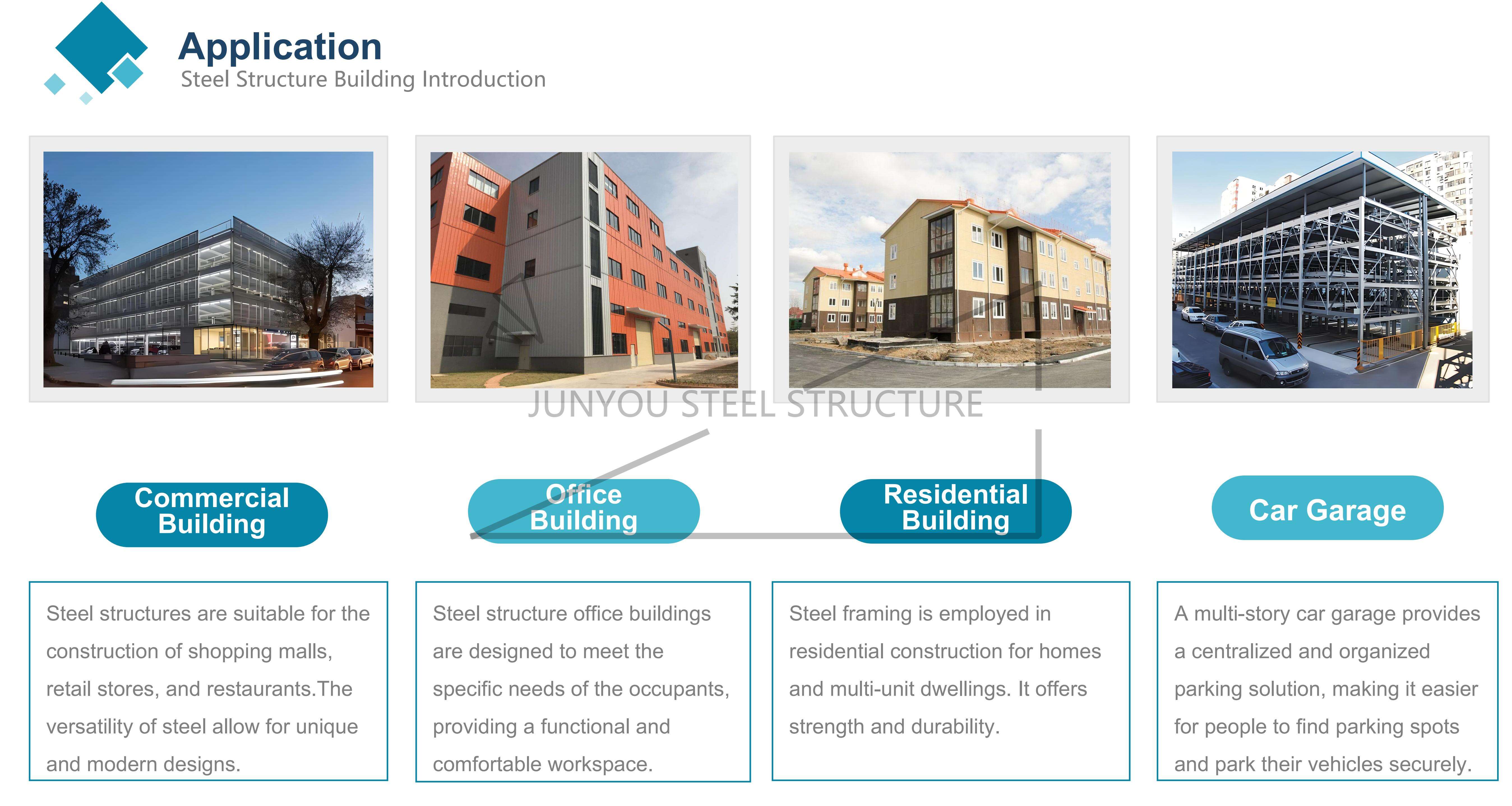

Application: Steel building

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

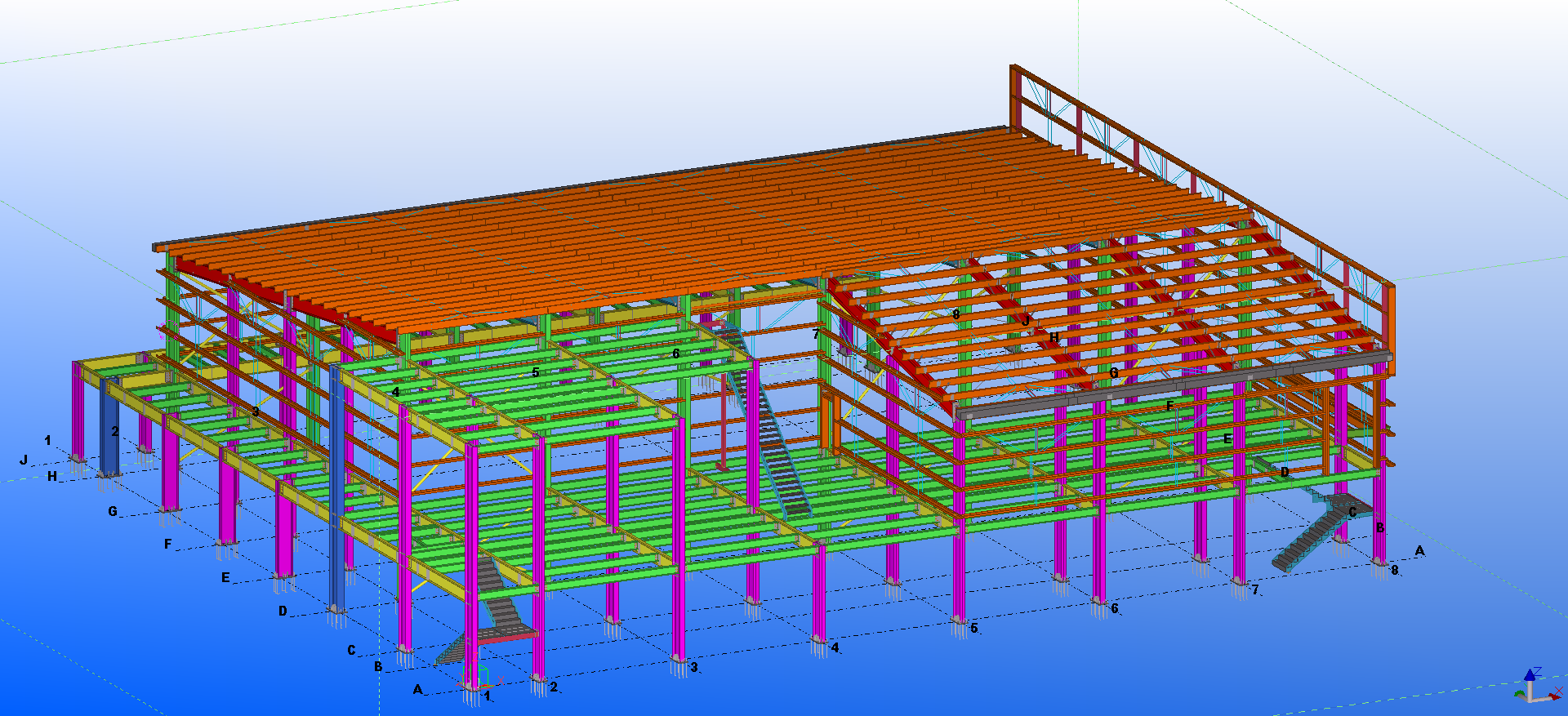

A prefabricated 2-storey steel structure building is an ideal choice for an industrial workshop or warehouse. This kind of design maximizes space utilization, allowing for separate areas on each floor to accommodate different workshop functions.

It's an integrated ventilation system, which promotes optimal air circulation, regulates temperature, and removes fumes and moisture—creating a safer and more productive environment for any application.

Installation Video of Prefabricated Steel Structure Building

A Closer Look at Our Steel Building Project

First Floor Images

Second Floor Images

Front Side Images

This 2-story prefabricated steel structure building features an exceptional 9-meter height per floor, reaching a total height of 18 meters. The design element includes a three-story office space constructed at the corner of the steel building.

The main workshop area is covered by single steel sheets for walls and roofing, providing a durable and cost-effective enclosure. While the office section utilizes traditional brick walls. This material choice significantly enhances thermal insulation and soundproofing, creating a quiet and comfortable working environment for office personnel.

The large span, open-plan workshop is flooded with natural light, fostering a bright and productive atmosphere. This optimal layout ensures orderly, efficient, and high-speed production operations.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

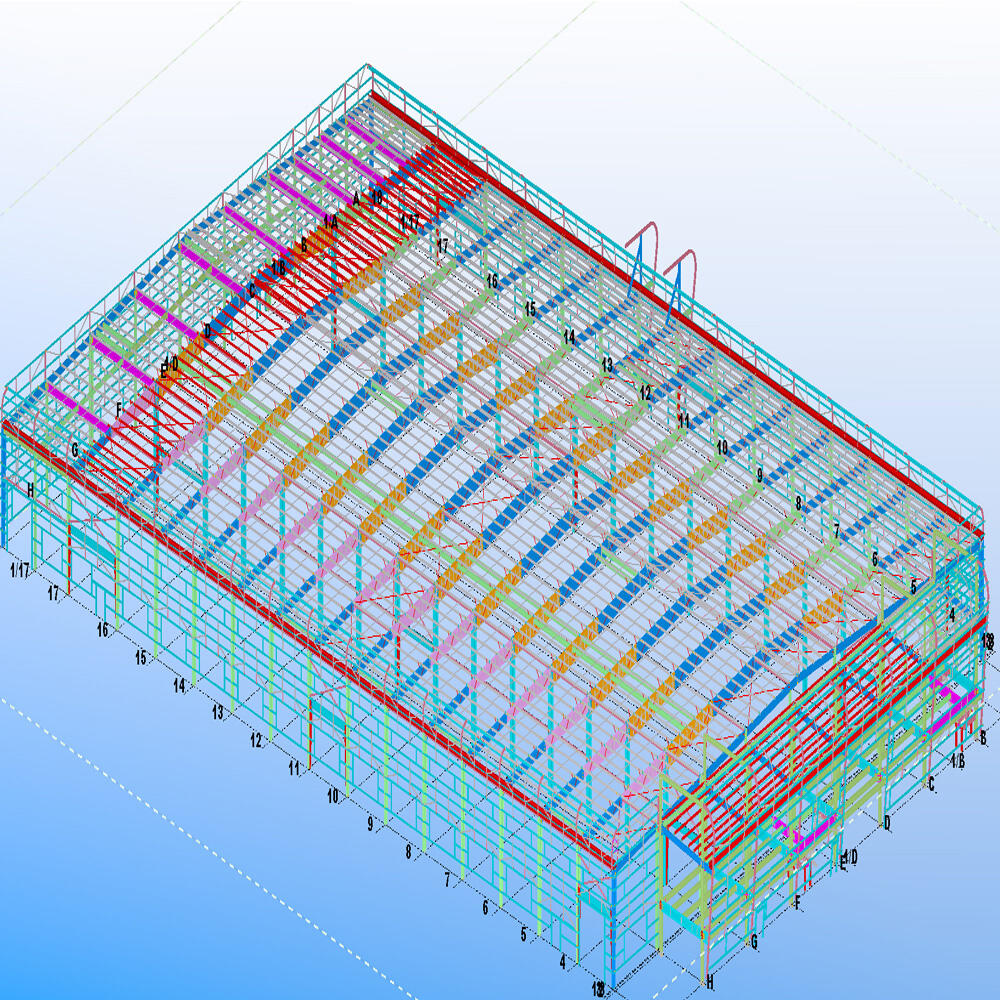

Steel building design

Our experienced design department has extensive practical expertise in completing the structural design of steel buildings in compliance with Chinese design codes and local regulations. Every design is optimized to ensure structural safety, reasonable layout, and cost-effective steel consumption.

For overseas projects, structural design must follow the local building codes and standards (such as Euro standards or US standards). We will provide the necessary drawings and detailing to support the local registered engineers in completing the design.

We also provide structural detailing, 3D modeling, fabrication drawings, and installation shop drawings, ensuring accurate and efficient construction.

Whether you need a warehouse, workshop, office building, or industrial facility, our steel structural design solutions provide strength, durability, and efficiency from concept to construction.

Step-by-Step Steel Building Construction Process

Construction Step |

Description |

1. Structural Design |

Engineering analysis to determine load capacity, span, wind/snow resistance, and layout configuration. |

2. Steel Fabrication |

Prefabrication of columns, beams, purlins, and bracings based on custom design and material specs. |

3. Welding & Processing |

Welding and cutting components in the factory to ensure accuracy and efficiency. |

4. On-Site Assembly |

Bolting or welding frames, purlins, and cladding together according to construction drawings. |

5. Roofing & Cladding |

Installation of roof panels, wall panels, insulation, and waterproofing layers. |

6. Final Finishing |

Installation of doors, windows, gutters, ridge caps, and trim. |

Why Prefabricated Steel Buildings Are Popular Worldwide?

Steel structure buildings are widely recognized for their strength, flexibility, and cost-efficiency. With fast construction speed and long service life, prefabricated steel buildings have become a preferred solution in multiple industries worldwide.

Get Your Custom Steel Structure Building Today

Looking for a durable, cost-effective steel structure building for your next project? We offer customized design, high-quality fabrication, and professional installation services for industrial, commercial, and agricultural use.

E-mail: [email protected]

Phone: +86-13535848691