Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Steel warehouses are essential for businesses across various industries that require secure, large-scale storage solutions. These structures are ideal for temporarily holding goods in bulk before distribution—either to other facilities or directly to end customers.

An industrial steel warehouse is specifically engineered to support a wide range of operations, including manufacturing, assembly, packaging, and storage of raw materials or finished products. With durable steel frames and customizable layouts, our warehouses ensure maximum space utilization and long-term performance in demanding environments.

On-Site Steel warehouse Installation

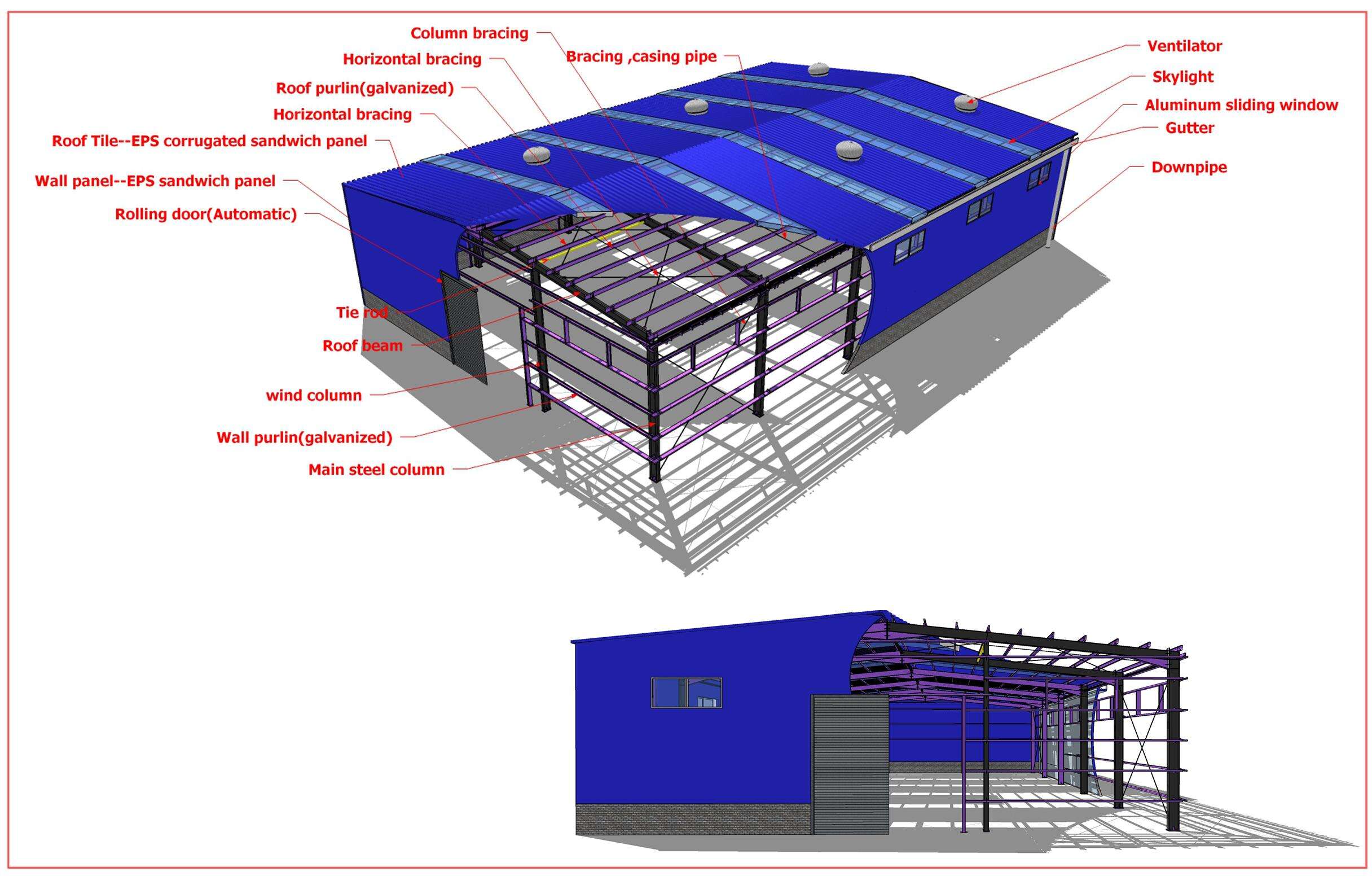

Key Components of Our Steel Warehouse Buildings

✅ Steel Framing System

Welded H-beams and high-strength purlin bracing ensure maximum structural stability. Engineered to withstand heavy loads, high winds, and seismic activity.

✅ Durable Roof & Wall Panels

Made from galvanized steel sheets or insulated sandwich panels for superior weather resistance.

Options include corrugated metal, PIR/PUR foam panels, or fire-resistant cladding.

✅ Functional Doors & Windows

Overhead sectional doors, roller shutters, or high-speed doors for smooth logistics operations.

Natural ventilation windows or skylights to improve airflow and reduce energy costs.

✅ Energy-Efficient Insulation

EPS, Fiberglass, rock wool, or PU panels maintain temperature control in cold storage or climate-sensitive environments. Reduces heating/cooling costs while enhancing workplace comfort.

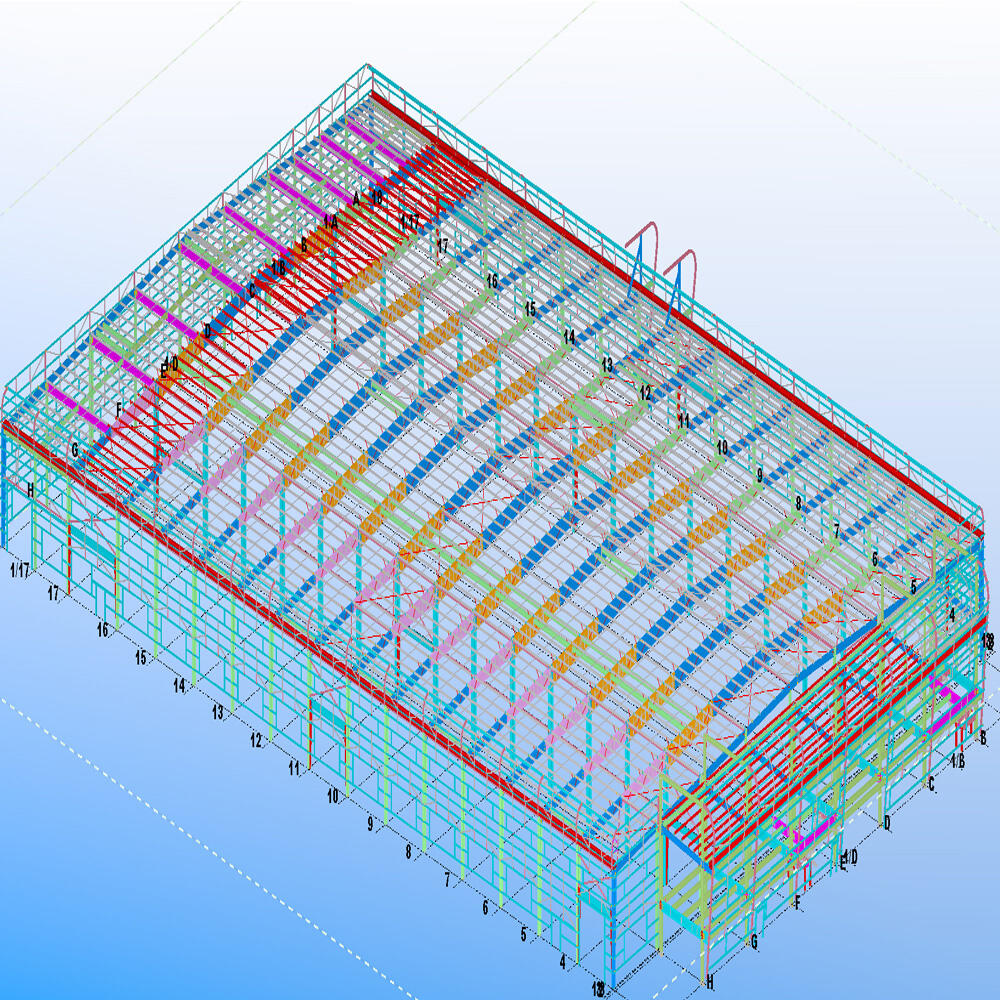

3D Steel Structure Warehouse Model Material Display

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Applications of Steel Warehouse Buildings

Steel structure warehouses are widely used across various sectors due to their strength, durability, and fast installation. These versatile buildings are ideal for both domestic and international markets, offering long-term performance with low maintenance.

Common applications include:

Advantages of Prefabricated Steel Warehouses

High-strength steel ensures long-lasting performance in industrial environments.

All parts are prefabricated, reducing on-site labor and speeding up construction.

Spacious interiors and wide entryways improve logistics and workflow efficiency.

Low construction waste, water-saving, and recyclable materials make it sustainable.

Heat-resistant panels provide safety and stable indoor temperatures.

Steel Warehouse vs. Traditional Building

Feature |

Steel Warehouse |

Traditional Building |

Durability |

High – corrosion & pest resistant |

Medium – prone to decay |

Construction Time |

Short – prefabricated |

Long – on-site processing |

Cost Efficiency |

Lower total cost |

Higher labor and material |

Environmental Impact |

Recyclable, low waste |

More resource-intensive |

Fire Resistance |

Yes – fireproof materials |

Varies – not always resistant |

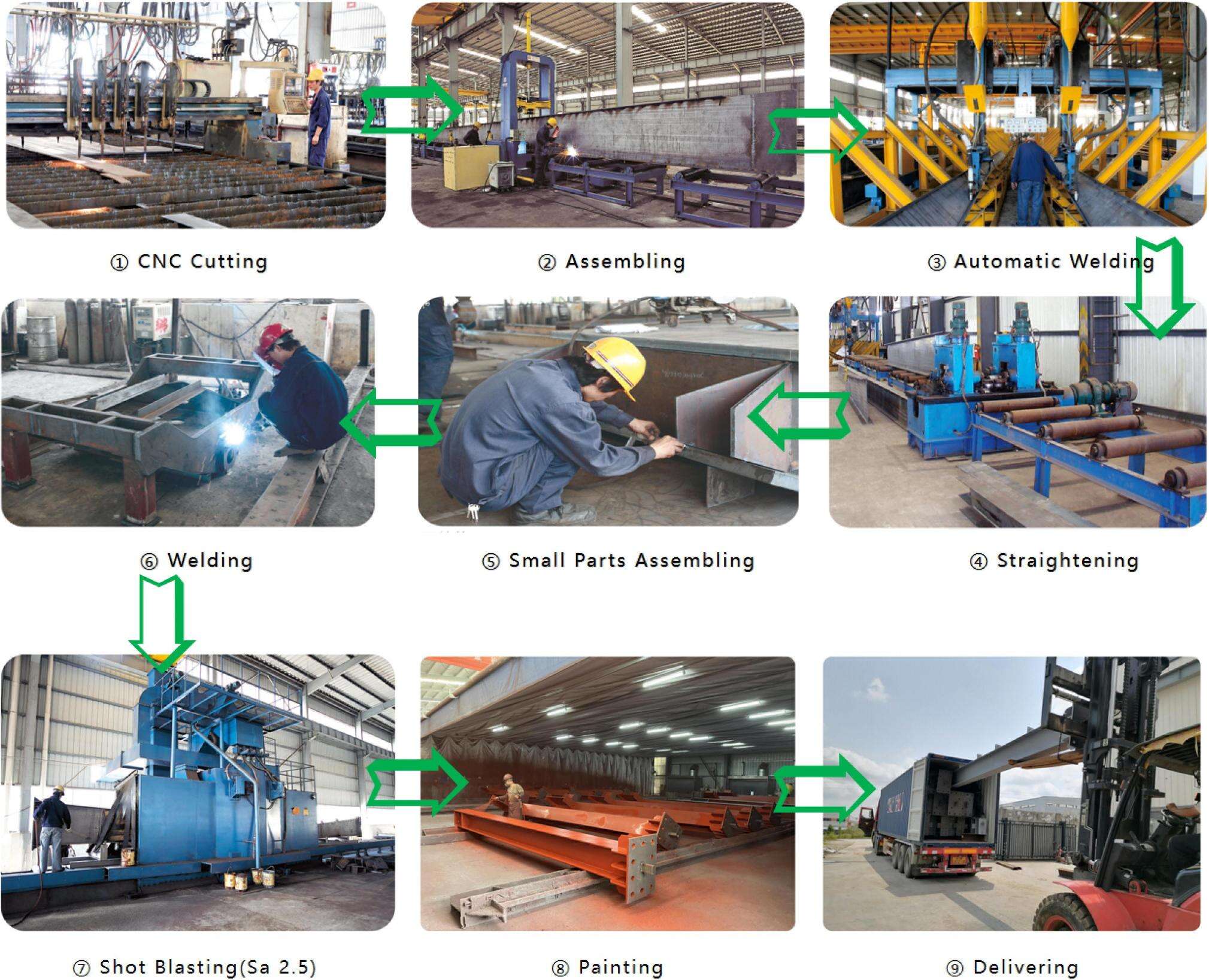

Steel Warehouse Fabrication Process:

Contact Us to Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691