Steel Grade: Q235B/Q355B (GB standard)

Application: Steel workshop

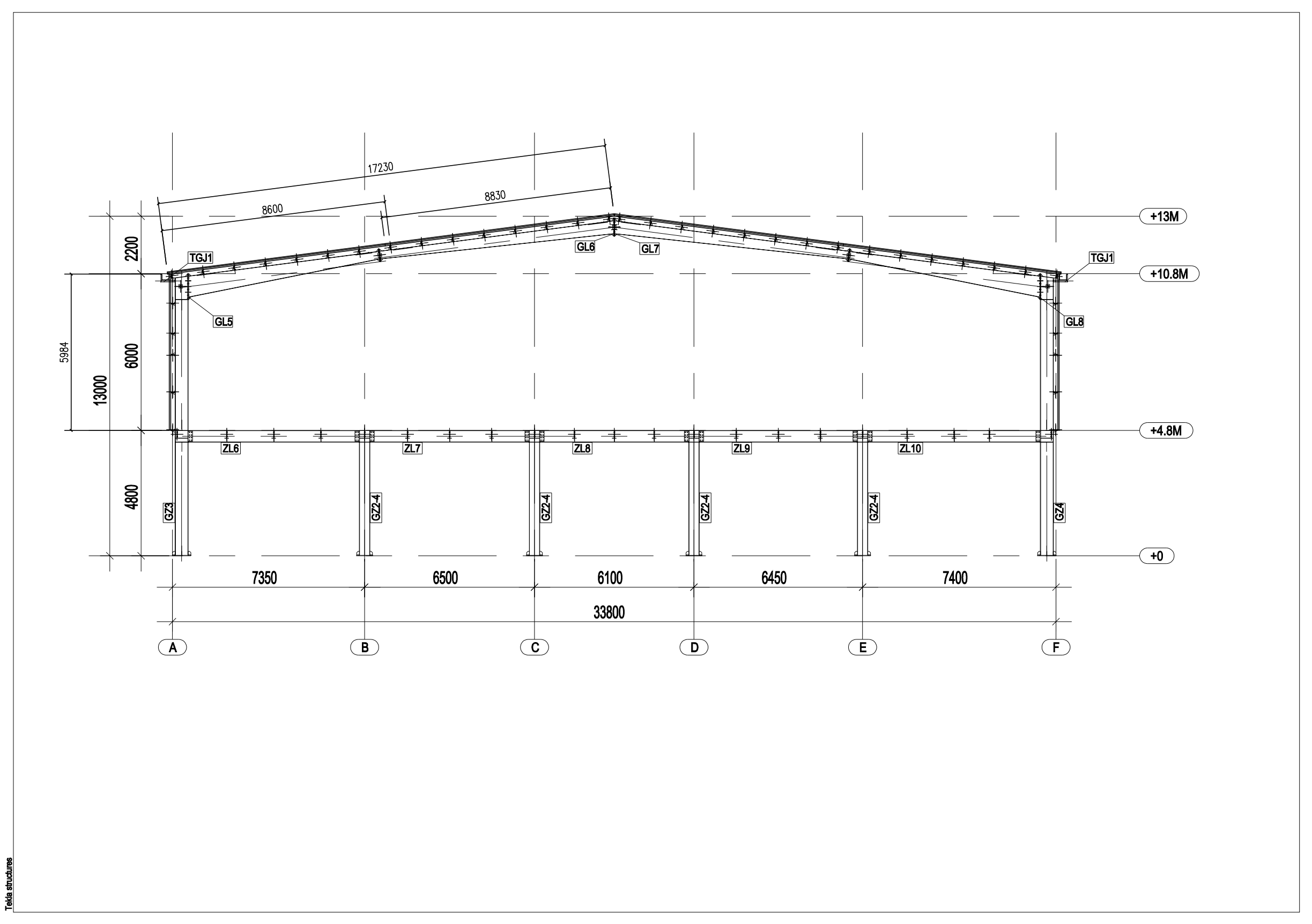

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

A steel workshop with mezzanine is a highly efficient and space-saving solution for industrial and commercial use. This type of structure combines the strength and durability of a steel frame workshop with the added functionality of a mezzanine floor, creating extra usable space for offices, storage, or light manufacturing.

Steel workshop construction with mezzanine is ideal for businesses that require vertical space optimization without increasing the building footprint. Designed with customizable spans, heights, and load-bearing capacity, this solution offers flexibility, fast installation, and long-term cost efficiency—making it a popular choice in modern steel building projects.

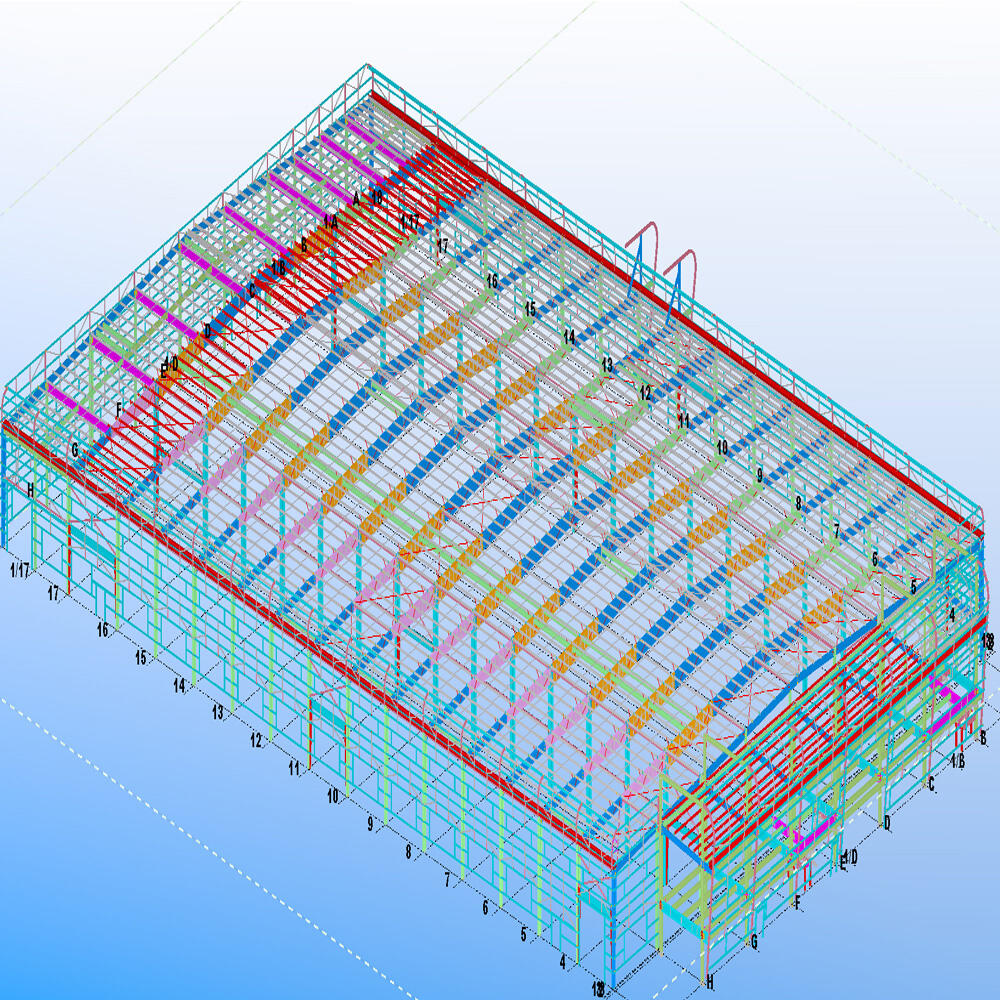

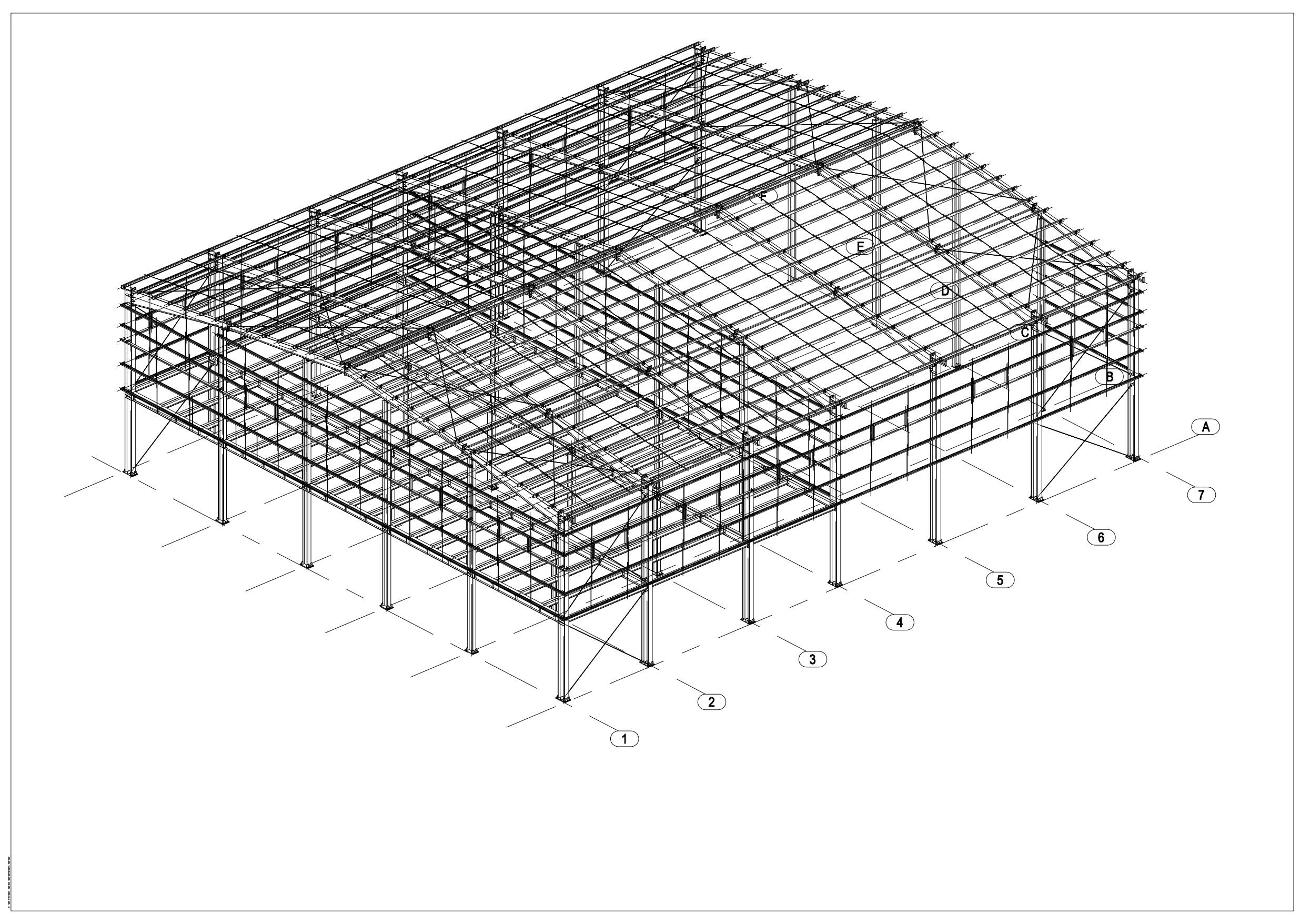

Steel Workshop drawing & Installation

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Steel Structure Workshops Features

Steel structure workshops are widely used in industries such as manufacturing, warehousing, automotive repair, and construction, where a large open-span space is essential to accommodate heavy machinery, equipment, and staff movement.

● These steel workshops offer multiple advantages:

● Cost-effective construction with lower labor and foundation costs

● Wide clear-span design for maximum interior flexibility

● Lightweight yet high-strength steel framing

● Quick and easy assembly, reducing project timelines

● Fire-resistant and windproof structure, ensuring workplace safety

● Earthquake-resistant design, suitable for high-seismic regions

● Durable and low-maintenance materials for long-term use

● Eco-friendly building solution, with recyclable components and reduced site waste

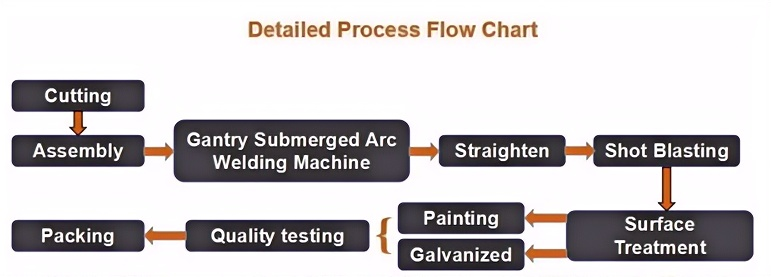

Steel Workshop Fabrication Process:

Why Choose Us for Your Steel Structure Project

1. Experienced Team

Our engineers have over 10 years of experience in steel structure design and construction. Skilled workers ensure high-quality steel processing, and many have overseas installation experience. Our responsive and professional sales team provides timely support and clear communication from inquiry to delivery.

2. Comprehensive Service

We offer free layout plans, elevation drawings, and detailed quotations during the pre-sale stage. After order confirmation, we provide construction drawings, structural calculation sheets (for permit applications), and foundation & installation guides. Every container comes with a complete packing list, and we can supply Form A, Form E, and CO certificates as needed.

3. Advanced Manufacturing Equipment

Our factory is equipped with more than 10 sets of advanced processing machines, including gantry planers, automatic submerged arc welders, assembling lines, and shot blasting machines, ensuring precision and efficiency in every steel structure component

Contact us today for a custom steel workshop solution!

E-mail: [email protected]

Phone: +86-13535848691