| Availability: | |

|---|---|

| Quantity: | |

Product Information

The prefab house built with sandwich panels,also known as a sandwich panel modular house or a sandwich panel prefabricated house, is a type of prefabricated housing structure that use sandwich panels as its primary building material. It has the characteristics of stable structure, fast construction, reusable, etc., and is suitable for a variety of uses such as temporary buildings, construction site dormitories, office places, and warehouses.

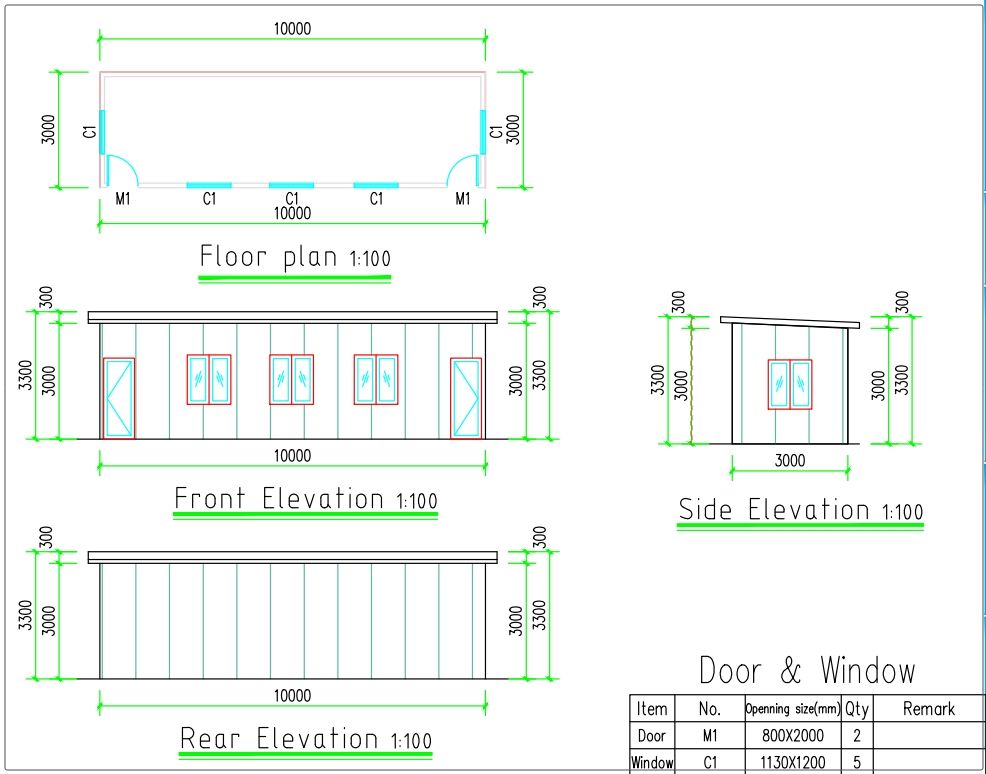

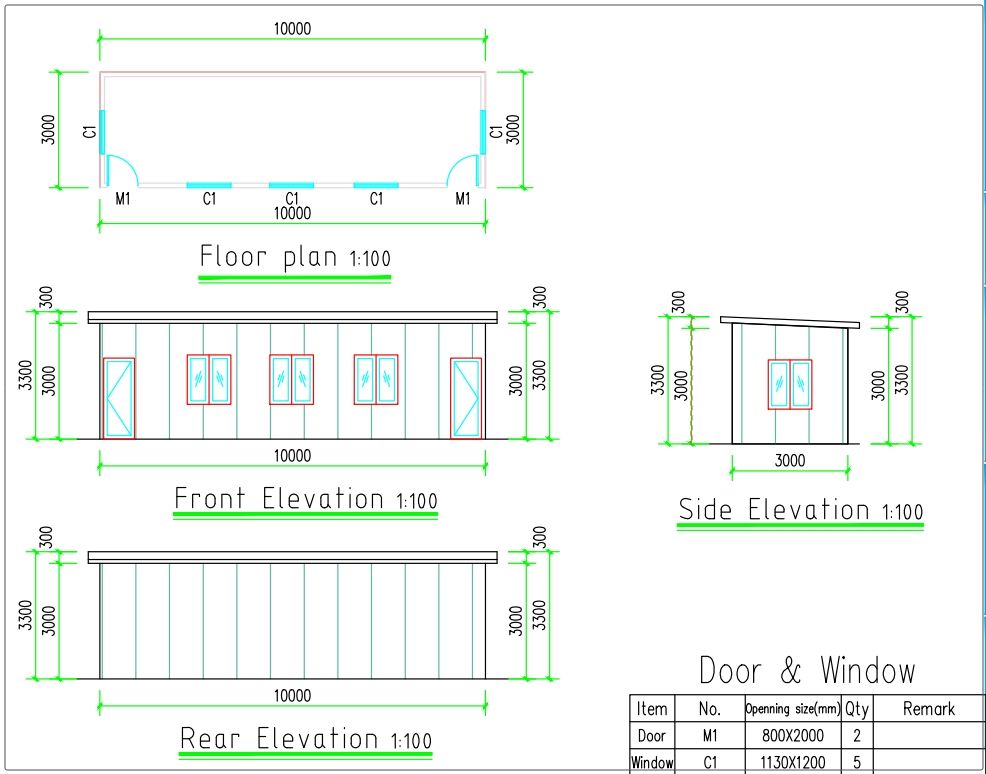

The house product we mentioned here is a temporary house in the countryside. Usually, it is for farmers' resting places or storage tools. It is the most simple design but looks clean and comfortable. The below are the project pictures and drawing display:

The prefab house wall & roof type:

In a sandwich panel prefab house, the walls, roof, and sometimes even the ceiling are constructed using sandwich

panels. A sandwich panel consists of three main layers: an inner and outer layer, typically steel sheet and a core material in between.

The core material is often made of insulating materials like expanded polystyrene (EPS), polyurethane (PU), fiber glass or rock wool. These layers are bonded to form a strong, lightweight, and energy-efficient panel, and some of them are fire proof.

Choose appropriate sandwich panel for wall & roof is important

Wall & Roof panel | Fireproof | Cost(A-D↓) | Density |

| EPS(polystyrene) sandwich panel | NO | D | 8~14 kg/m3 |

Glass wool sandwich panel | YES | C | 8~20kg/m3 |

Rock wool sandwich panel | YES | B | 60~120/m3 |

PU(Polyurethane) sandwich panel | YES | A | 10~40/m3 |

Sandwich panel prefab houses offer several advantages:

Speed of Construction: Prefabricated construction allows for faster assembly than traditional on-site construction. The panels are manufactured in advance, reducing the construction time required on-site.

Cost-Effective: Prefabricated houses can be more cost-effective than traditional construction methods. The controlled factory environment ensures efficient use of materials and reduces waste. Additionally, the streamlined construction process can save labor costs.

Energy Efficiency: The insulating core material of sandwich panels provides excellent thermal insulation, helping to maintain comfortable indoor temperatures and reduce energy consumption for heating or cooling.

Structural Strength: Sandwich panels have high strength-to-weight ratios, making them durable and capable of withstanding various environmental conditions. They offer good resistance to impacts, wind, and seismic forces.

Design Flexibility: Prefabricated houses can be customized to meet specific design requirements and aesthetic preferences. They offer flexibility in terms of layout, finishes, and architectural styles.

Portability and Reusability: Sandwich panel prefab houses are often designed to be easily disassembled and relocated if needed. This feature makes them suitable for temporary housing, remote locations, or situations requiring mobility.

Metal building prefab house kit applications

This T prefabricated house is the most economical design & is commonly used in construction sites, oil sites, and mining sites as workers' quarters, and site offices, also used for solider camps, government projects & school projects as labor accommodation, solider accommodation, employee accommodation, student dormitory, teacher`s office, engineers office, site offices, canteen, clinic, laundry room etc.

Prefab house building material component

No. | Material | Specification |

I | Accessories parts | |

1 |

| bolts,screws,glue |

II | Main steel frame | |

1 |

| 口80*1.5 |

2 |

| C80*35*1.5 |

3 |

| C80*35*1.5 |

4 |

| C80*35*1.5 |

5 |

| L50*3.0 |

6 |

| 3~8mm steel sheet |

7 | Structure steel fabrication+Sanding +Painting | Acetylene, oxygen, electrode, Sa2.5 |

III | Maintenance | |

1 |

| 50mm, steel sheet 0.326mm |

2 |

| 50mm, steel sheet 0.326mm |

3 |

| 50mm, steel sheet 0.326mm |

4 |

| 50mm width |

5 |

| 50mm width |

6 |

| steel sheet |

IV | Door&Window | |

1 |

| Prefab house type |

2 |

| 50mm EPS sandwich panel |

3 |

| W925*H1000 |

Prefabricated house container loading method:

A simple structure system means not that many complicated components, which is easy for transportation,about 200~250sqm T-House can be fit into a standard 40' container.

In which country are sandwich panel houses more popular?

Sandwich panel prefab houses are popular in many countries around the world. The countries where we have exported this kind of prefabricated houses are concentrated in Southeast Asia: Indonesia, Malaysia, Philippines, Thailand, Myanmar, Brunei, and also East Timor. It seems these countries have a significant demand for affordable and quick housing solutions, making sandwich panel prefab houses a popular choice. There countries have seen a rise in the use of prefab construction methods for residential and commercial buildings.

Product Information

The prefab house built with sandwich panels,also known as a sandwich panel modular house or a sandwich panel prefabricated house, is a type of prefabricated housing structure that use sandwich panels as its primary building material. It has the characteristics of stable structure, fast construction, reusable, etc., and is suitable for a variety of uses such as temporary buildings, construction site dormitories, office places, and warehouses.

The house product we mentioned here is a temporary house in the countryside. Usually, it is for farmers' resting places or storage tools. It is the most simple design but looks clean and comfortable. The below are the project pictures and drawing display:

The prefab house wall & roof type:

In a sandwich panel prefab house, the walls, roof, and sometimes even the ceiling are constructed using sandwich

panels. A sandwich panel consists of three main layers: an inner and outer layer, typically steel sheet and a core material in between.

The core material is often made of insulating materials like expanded polystyrene (EPS), polyurethane (PU), fiber glass or rock wool. These layers are bonded to form a strong, lightweight, and energy-efficient panel, and some of them are fire proof.

Choose appropriate sandwich panel for wall & roof is important

Wall & Roof panel | Fireproof | Cost(A-D↓) | Density |

| EPS(polystyrene) sandwich panel | NO | D | 8~14 kg/m3 |

Glass wool sandwich panel | YES | C | 8~20kg/m3 |

Rock wool sandwich panel | YES | B | 60~120/m3 |

PU(Polyurethane) sandwich panel | YES | A | 10~40/m3 |

Sandwich panel prefab houses offer several advantages:

Speed of Construction: Prefabricated construction allows for faster assembly than traditional on-site construction. The panels are manufactured in advance, reducing the construction time required on-site.

Cost-Effective: Prefabricated houses can be more cost-effective than traditional construction methods. The controlled factory environment ensures efficient use of materials and reduces waste. Additionally, the streamlined construction process can save labor costs.

Energy Efficiency: The insulating core material of sandwich panels provides excellent thermal insulation, helping to maintain comfortable indoor temperatures and reduce energy consumption for heating or cooling.

Structural Strength: Sandwich panels have high strength-to-weight ratios, making them durable and capable of withstanding various environmental conditions. They offer good resistance to impacts, wind, and seismic forces.

Design Flexibility: Prefabricated houses can be customized to meet specific design requirements and aesthetic preferences. They offer flexibility in terms of layout, finishes, and architectural styles.

Portability and Reusability: Sandwich panel prefab houses are often designed to be easily disassembled and relocated if needed. This feature makes them suitable for temporary housing, remote locations, or situations requiring mobility.

Metal building prefab house kit applications

This T prefabricated house is the most economical design & is commonly used in construction sites, oil sites, and mining sites as workers' quarters, and site offices, also used for solider camps, government projects & school projects as labor accommodation, solider accommodation, employee accommodation, student dormitory, teacher`s office, engineers office, site offices, canteen, clinic, laundry room etc.

Prefab house building material component

No. | Material | Specification |

I | Accessories parts | |

1 |

| bolts,screws,glue |

II | Main steel frame | |

1 |

| 口80*1.5 |

2 |

| C80*35*1.5 |

3 |

| C80*35*1.5 |

4 |

| C80*35*1.5 |

5 |

| L50*3.0 |

6 |

| 3~8mm steel sheet |

7 | Structure steel fabrication+Sanding +Painting | Acetylene, oxygen, electrode, Sa2.5 |

III | Maintenance | |

1 |

| 50mm, steel sheet 0.326mm |

2 |

| 50mm, steel sheet 0.326mm |

3 |

| 50mm, steel sheet 0.326mm |

4 |

| 50mm width |

5 |

| 50mm width |

6 |

| steel sheet |

IV | Door&Window | |

1 |

| Prefab house type |

2 |

| 50mm EPS sandwich panel |

3 |

| W925*H1000 |

Prefabricated house container loading method:

A simple structure system means not that many complicated components, which is easy for transportation,about 200~250sqm T-House can be fit into a standard 40' container.

In which country are sandwich panel houses more popular?

Sandwich panel prefab houses are popular in many countries around the world. The countries where we have exported this kind of prefabricated houses are concentrated in Southeast Asia: Indonesia, Malaysia, Philippines, Thailand, Myanmar, Brunei, and also East Timor. It seems these countries have a significant demand for affordable and quick housing solutions, making sandwich panel prefab houses a popular choice. There countries have seen a rise in the use of prefab construction methods for residential and commercial buildings.