| Availability: | |

|---|---|

| Quantity: | |

Product Information

Sandwich panel prefab house also call prefabricated house, mobile house and portable house are houses assembled with light steel frame and sandwich panels.

The sandwich panel we mentioned here is a composite panel made of two layers of metal plates (such as steel plates) as the surface layer, and the middle is filled with thermal insulation, sound insulation and other materials (such as polystyrene foam, rock wool, etc.).This type of panel has the advantages of light weight, high strength, good thermal insulation performance, and easy installation.

Choose appropriate sandwich panel for wall & roof is important

Wall & Roof panel | Fireproof | Cost(A-D↓) | Density |

| EPS(polystyrene) sandwich panel | NO | D | 8~14 kg/m3 |

Glass wool sandwich panel | YES | C | 8~20kg/m3 |

Rock wool sandwich panel | YES | B | 60~120/m3 |

PU(Polyurethane) sandwich panel | YES | A | 10~40/m3 |

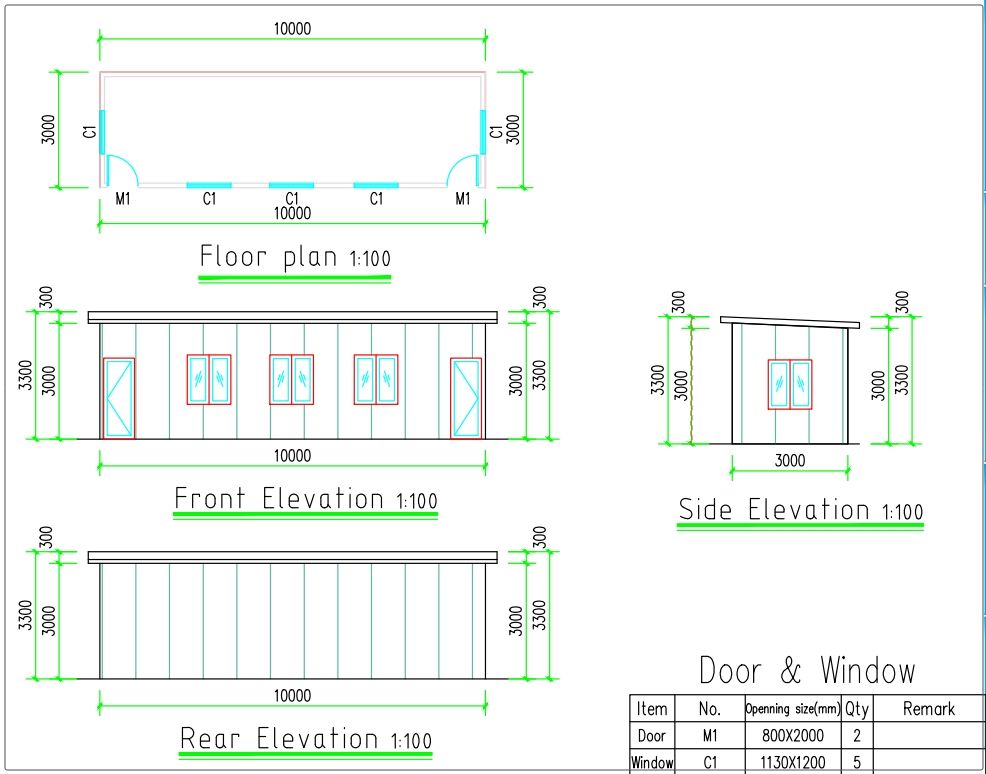

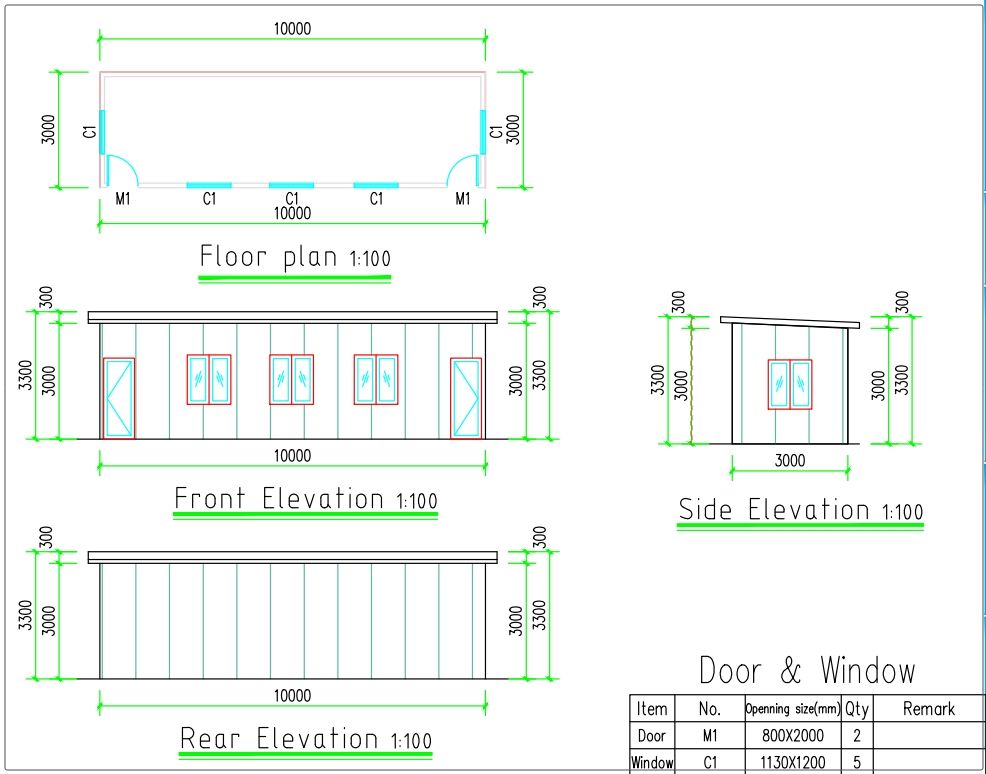

The product we introduce is a one floor flat roof prefabricated house for the workers' dormitory on a construction site. The workers' temporary dwellings do not have a gorgeous appearance but are simple, clean, and comfortable. Below is the project pictures and drawing display:

Steel frame building prefab house kit applications

This prefabricated house is the most economical design & is commonly used in construction sites, oil sites, and mining sites as workers' quarters, and site offices, also used for solider camps, government projects & school projects as labor accommodation, solider accommodation, employee accommodation, student dormitory, teacher`s office, engineers office, site offices, canteen, clinic, laundry room etc.

Prefabricated house Features

Easy Transporting: A simple structure system means not that many complicated components, which is easy for transportation,about 200~250sqm house can be fit into a standard 40' container.

Nice Appearance: The spacing between columns is wider and columns are hidden inside of the building the external appearance is much neater and more beautiful.

High Performance: The building has excellent thermal and insulation performance by adopting the splicing of wall panels.

Environmental Friendly: Factory prefabricated work, minimizing the onsite work and the construction waste. very environmentally friendly.

Material List detailed display

No. | Material | Specification |

I | Accessories parts | |

1 |

| bolts,screws,glue |

II | Main steel frame | |

1 |

| 口80*1.5 |

2 |

| C80*35*1.5 |

3 |

| C80*35*1.5 |

4 |

| C80*35*1.5 |

5 |

| L50*3.0 |

6 |

| 3~8mm steel sheet |

7 | Structure steel fabrication+Sanding +Painting | Acetylene, oxygen, electrode, Sa2.5 |

III | Maintenance | |

1 |

| 50mm, steel sheet 0.326mm |

2 |

| 50mm, steel sheet 0.326mm |

3 |

| 50mm, steel sheet 0.326mm |

4 |

| 50mm width |

5 |

| 50mm width |

6 |

| steel sheet |

IV | Door&Window | |

1 |

| Prefab house type |

2 |

| 50mm EPS sandwich panel |

3 |

| W925*H1000 |

Prefab house container loading method

Why metal frame prefabricated house is popular?

The lifespan of a prefab house can vary depending on several factors, including the quality of construction, materials used, maintenance practices, and environmental conditions. However, with proper care and maintenance, a well-built prefab house can have a lifespan of around 10~15 years.

The metal frame prefab house market can vary by region, as local regulations, cultural preferences, and economic factors influence the adoption and acceptance of prefab construction methods.

However, the overall market for prefab houses, including those with metal frames, is expected to continue growing as the demand for affordable, sustainable, and efficient housing solutions persists.

Product Information

Sandwich panel prefab house also call prefabricated house, mobile house and portable house are houses assembled with light steel frame and sandwich panels.

The sandwich panel we mentioned here is a composite panel made of two layers of metal plates (such as steel plates) as the surface layer, and the middle is filled with thermal insulation, sound insulation and other materials (such as polystyrene foam, rock wool, etc.).This type of panel has the advantages of light weight, high strength, good thermal insulation performance, and easy installation.

Choose appropriate sandwich panel for wall & roof is important

Wall & Roof panel | Fireproof | Cost(A-D↓) | Density |

| EPS(polystyrene) sandwich panel | NO | D | 8~14 kg/m3 |

Glass wool sandwich panel | YES | C | 8~20kg/m3 |

Rock wool sandwich panel | YES | B | 60~120/m3 |

PU(Polyurethane) sandwich panel | YES | A | 10~40/m3 |

The product we introduce is a one floor flat roof prefabricated house for the workers' dormitory on a construction site. The workers' temporary dwellings do not have a gorgeous appearance but are simple, clean, and comfortable. Below is the project pictures and drawing display:

Steel frame building prefab house kit applications

This prefabricated house is the most economical design & is commonly used in construction sites, oil sites, and mining sites as workers' quarters, and site offices, also used for solider camps, government projects & school projects as labor accommodation, solider accommodation, employee accommodation, student dormitory, teacher`s office, engineers office, site offices, canteen, clinic, laundry room etc.

Prefabricated house Features

Easy Transporting: A simple structure system means not that many complicated components, which is easy for transportation,about 200~250sqm house can be fit into a standard 40' container.

Nice Appearance: The spacing between columns is wider and columns are hidden inside of the building the external appearance is much neater and more beautiful.

High Performance: The building has excellent thermal and insulation performance by adopting the splicing of wall panels.

Environmental Friendly: Factory prefabricated work, minimizing the onsite work and the construction waste. very environmentally friendly.

Material List detailed display

No. | Material | Specification |

I | Accessories parts | |

1 |

| bolts,screws,glue |

II | Main steel frame | |

1 |

| 口80*1.5 |

2 |

| C80*35*1.5 |

3 |

| C80*35*1.5 |

4 |

| C80*35*1.5 |

5 |

| L50*3.0 |

6 |

| 3~8mm steel sheet |

7 | Structure steel fabrication+Sanding +Painting | Acetylene, oxygen, electrode, Sa2.5 |

III | Maintenance | |

1 |

| 50mm, steel sheet 0.326mm |

2 |

| 50mm, steel sheet 0.326mm |

3 |

| 50mm, steel sheet 0.326mm |

4 |

| 50mm width |

5 |

| 50mm width |

6 |

| steel sheet |

IV | Door&Window | |

1 |

| Prefab house type |

2 |

| 50mm EPS sandwich panel |

3 |

| W925*H1000 |

Prefab house container loading method

Why metal frame prefabricated house is popular?

The lifespan of a prefab house can vary depending on several factors, including the quality of construction, materials used, maintenance practices, and environmental conditions. However, with proper care and maintenance, a well-built prefab house can have a lifespan of around 10~15 years.

The metal frame prefab house market can vary by region, as local regulations, cultural preferences, and economic factors influence the adoption and acceptance of prefab construction methods.

However, the overall market for prefab houses, including those with metal frames, is expected to continue growing as the demand for affordable, sustainable, and efficient housing solutions persists.