Product Information

The prefabricated T house is also called the flat roof prefab house. It is a type of temporary building using the steel structure frame as the fundamental system for the floor load bearing, and sandwich panels as the main cladding building materials for the wall and roof. This kind of panel usually consists of two exterior layers(color-bond steel sheet) filled with an insulating core. The thermal insulation core material can be made of polystyrene(EPS), polyurethane(PU), rock wool, and fiberglass wool which have excellent thermal insulation properties.

Not like the K house, the design of the T House(1T=1150mm)steel structure framing is inside the house, which means you can not see the steel frame from outside. The steel structure for the T house is usually square tube as the columns and the roof truss beam. That will make the external and internal appearances neater and more beautiful, the layouts are more flexible, and the thermal and sound insulating performances are much better.

Prefab house building material component

No. | Material | Specification |

I | Accessories parts | |

1 |

| bolts,screws,glue |

II | Main steel frame | |

1 |

| 口80*1.5 |

2 |

| C80*35*1.5 |

3 |

| C80*35*1.5 |

4 |

| C80*35*1.5 |

5 |

| L50*3.0 |

6 |

| 3~8mm steel sheet |

7 | Structure steel fabrication+Sanding +Painting | Acetylene, oxygen, electrode, Sa2.5 |

III | Maintenance | |

1 |

| 50mm, steel sheet 0.326mm |

2 |

| 50mm, steel sheet 0.326mm |

3 |

| 50mm, steel sheet 0.326mm |

4 |

| 50mm width |

5 |

| 50mm width |

6 |

| steel sheet |

IV | Door&Window | |

1 |

| Prefab house type |

2 |

| 50mm EPS sandwich panel |

3 |

| W925*H1000 |

Prefabricated T house application

This product is often used in a wide range of applications such as construction sites, campsites, government low-cost housing, public events, commercial events, residential buildings, offices, schools, and even in remote or challenging locations. Their durability, cost-effectiveness, and ease of construction make them a popular choice for many projects. As technology and design advance, sandwich panel prefab homes continue to gain popularity as a sustainable and efficient alternative to traditional construction.

Here below pls see some prefab house project samples:

1)Residential house

They are widely used for residential purposes, because they offer cost-effective and quick construction solutions for individual homes, housing communities, and affordable housing projects.

2)Commercial buildings

Sandwich panel prefab houses can also be used for commercial buildings such as offices, schools, healthcare facilities,toilet, canteen and retail spaces. Their quick assembly and versatility make them suitable for various commercial applications.

3)Industrial facilities

Sandwich panel prefab houses are commonly used for industrial facilities, including factories, warehouses, workshops, and storage buildings. These structures provide efficient and durable spaces for industrial operations.

4)Temporary housing: Sandwich panel prefab houses are often used as temporary shelters in emergency situations such as natural disasters or refugee camps. Their easy transportation and assembly make them suitable for providing quick and temporary housing solutions.

Prefabricated T house advantage

/ Easy Transporting: A simple structure system means not that many complicated components, which is easy for transportation,about 200~250sqm T-House can be fit into a standard 40' container.

/ Nice Appearance: The spacing between columns is wider and columns are hidden inside of the building the external appearance is much neater and more beautiful.

/ High Performance: The building has excellent thermal and insulation performance by adopting the splicing of wall panels.

/ Environmental Friendly: Factory prefabricated work, minimizing the onsite work and the construction waste. very environmentally friendly.

/Flexible design: They provide great flexibility in design and can be customized to meet specific requirements. These panels can be configured to create various floor plans enabling personalized design.

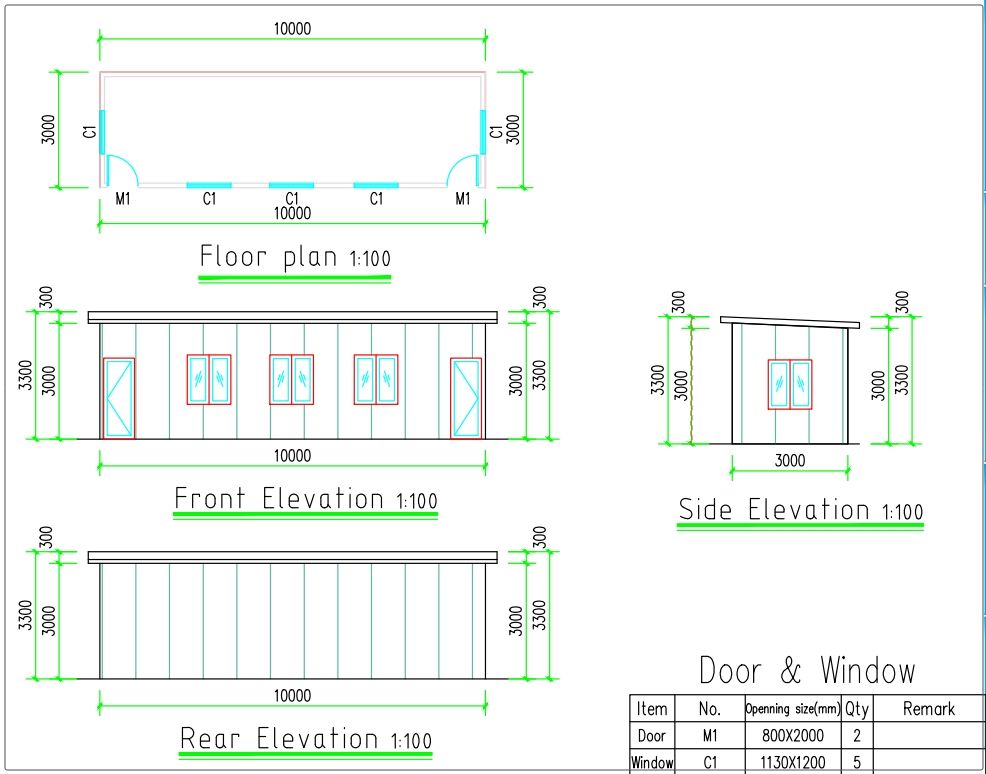

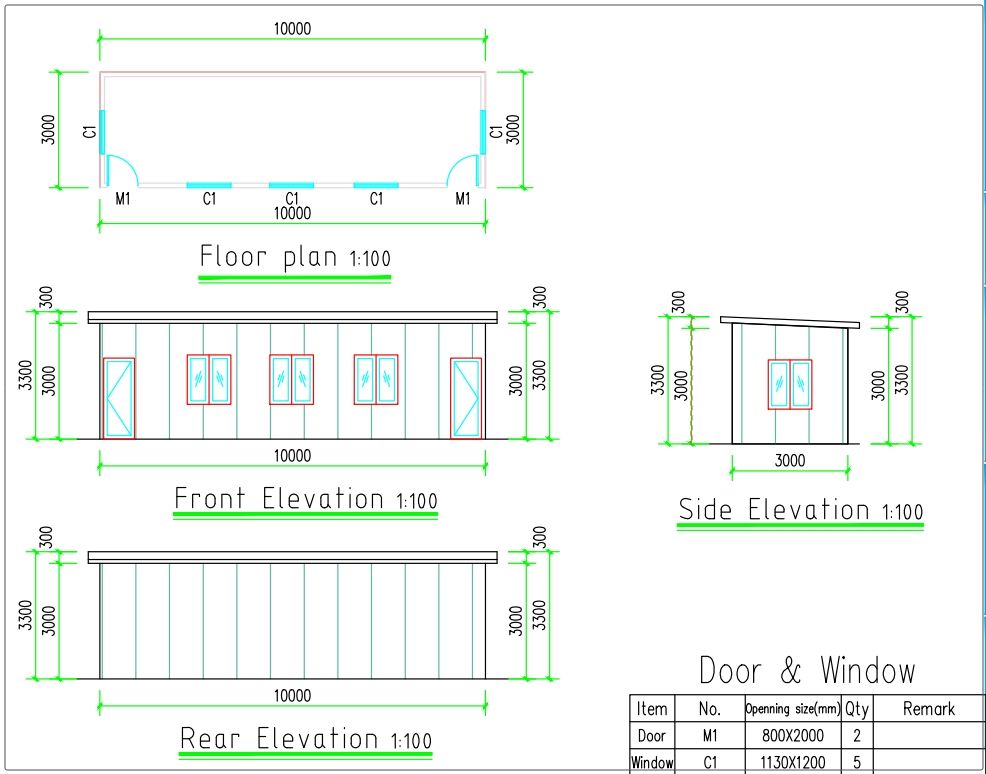

Here below is a simple sample for a prefab house as a small storage room:

Installtion tool

Prefab house is easy to install, we will offer you the installation drawing and you obtain some simple tools like:

electric pistol drill, electric impact drill, angle grinder, sawing machine, rivet gun, glass cement gun, slotted point screwdriver, adjustable wrench, A Type ladder, ect.

Choose appropriate sandwich panel for wall & roof is important

Wall & Roof panel | Fireproof | Cost(A-D↓) | Density |

| EPS(polystyrene) sandwich panel | NO | D | 8~14 kg/m3 |

Glass wool sandwich panel | YES | C | 8~20kg/m3 |

Rock wool sandwich panel | YES | B | 60~120/m3 |

PU(Polyurethane) sandwich panel | YES | A | 10~40/m3 |

In which country are sandwich panel houses more popular?

Sandwich panel prefab houses are popular in many countries around the world. The countries where we have exported this kind of prefabricated houses are concentrated in Southeast Asia: Indonesia, Malaysia, Philippines, Thailand, Myanmar, Brunei, and also East Timor. It seems these countries have a significant demand for affordable and quick housing solutions, making sandwich panel prefab houses a popular choice. There countries have seen a rise in the use of prefab construction methods for residential and commercial buildings.

Product Information

The prefabricated T house is also called the flat roof prefab house. It is a type of temporary building using the steel structure frame as the fundamental system for the floor load bearing, and sandwich panels as the main cladding building materials for the wall and roof. This kind of panel usually consists of two exterior layers(color-bond steel sheet) filled with an insulating core. The thermal insulation core material can be made of polystyrene(EPS), polyurethane(PU), rock wool, and fiberglass wool which have excellent thermal insulation properties.

Not like the K house, the design of the T House(1T=1150mm)steel structure framing is inside the house, which means you can not see the steel frame from outside. The steel structure for the T house is usually square tube as the columns and the roof truss beam. That will make the external and internal appearances neater and more beautiful, the layouts are more flexible, and the thermal and sound insulating performances are much better.

Prefab house building material component

No. | Material | Specification |

I | Accessories parts | |

1 |

| bolts,screws,glue |

II | Main steel frame | |

1 |

| 口80*1.5 |

2 |

| C80*35*1.5 |

3 |

| C80*35*1.5 |

4 |

| C80*35*1.5 |

5 |

| L50*3.0 |

6 |

| 3~8mm steel sheet |

7 | Structure steel fabrication+Sanding +Painting | Acetylene, oxygen, electrode, Sa2.5 |

III | Maintenance | |

1 |

| 50mm, steel sheet 0.326mm |

2 |

| 50mm, steel sheet 0.326mm |

3 |

| 50mm, steel sheet 0.326mm |

4 |

| 50mm width |

5 |

| 50mm width |

6 |

| steel sheet |

IV | Door&Window | |

1 |

| Prefab house type |

2 |

| 50mm EPS sandwich panel |

3 |

| W925*H1000 |

Prefabricated T house application

This product is often used in a wide range of applications such as construction sites, campsites, government low-cost housing, public events, commercial events, residential buildings, offices, schools, and even in remote or challenging locations. Their durability, cost-effectiveness, and ease of construction make them a popular choice for many projects. As technology and design advance, sandwich panel prefab homes continue to gain popularity as a sustainable and efficient alternative to traditional construction.

Here below pls see some prefab house project samples:

1)Residential house

They are widely used for residential purposes, because they offer cost-effective and quick construction solutions for individual homes, housing communities, and affordable housing projects.

2)Commercial buildings

Sandwich panel prefab houses can also be used for commercial buildings such as offices, schools, healthcare facilities,toilet, canteen and retail spaces. Their quick assembly and versatility make them suitable for various commercial applications.

3)Industrial facilities

Sandwich panel prefab houses are commonly used for industrial facilities, including factories, warehouses, workshops, and storage buildings. These structures provide efficient and durable spaces for industrial operations.

4)Temporary housing: Sandwich panel prefab houses are often used as temporary shelters in emergency situations such as natural disasters or refugee camps. Their easy transportation and assembly make them suitable for providing quick and temporary housing solutions.

Prefabricated T house advantage

/ Easy Transporting: A simple structure system means not that many complicated components, which is easy for transportation,about 200~250sqm T-House can be fit into a standard 40' container.

/ Nice Appearance: The spacing between columns is wider and columns are hidden inside of the building the external appearance is much neater and more beautiful.

/ High Performance: The building has excellent thermal and insulation performance by adopting the splicing of wall panels.

/ Environmental Friendly: Factory prefabricated work, minimizing the onsite work and the construction waste. very environmentally friendly.

/Flexible design: They provide great flexibility in design and can be customized to meet specific requirements. These panels can be configured to create various floor plans enabling personalized design.

Here below is a simple sample for a prefab house as a small storage room:

Installtion tool

Prefab house is easy to install, we will offer you the installation drawing and you obtain some simple tools like:

electric pistol drill, electric impact drill, angle grinder, sawing machine, rivet gun, glass cement gun, slotted point screwdriver, adjustable wrench, A Type ladder, ect.

Choose appropriate sandwich panel for wall & roof is important

Wall & Roof panel | Fireproof | Cost(A-D↓) | Density |

| EPS(polystyrene) sandwich panel | NO | D | 8~14 kg/m3 |

Glass wool sandwich panel | YES | C | 8~20kg/m3 |

Rock wool sandwich panel | YES | B | 60~120/m3 |

PU(Polyurethane) sandwich panel | YES | A | 10~40/m3 |

In which country are sandwich panel houses more popular?

Sandwich panel prefab houses are popular in many countries around the world. The countries where we have exported this kind of prefabricated houses are concentrated in Southeast Asia: Indonesia, Malaysia, Philippines, Thailand, Myanmar, Brunei, and also East Timor. It seems these countries have a significant demand for affordable and quick housing solutions, making sandwich panel prefab houses a popular choice. There countries have seen a rise in the use of prefab construction methods for residential and commercial buildings.