Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

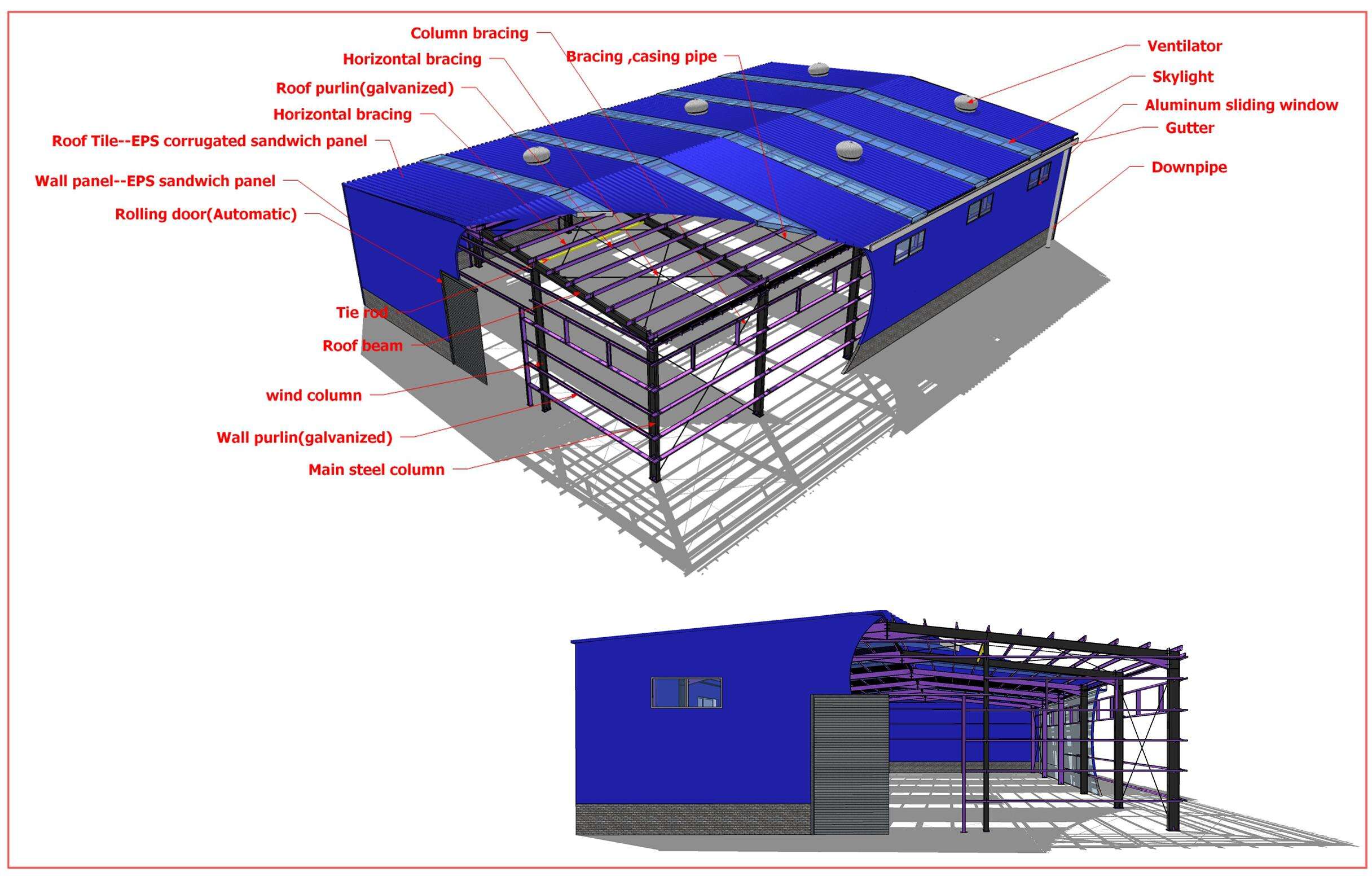

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Engineered for strength and longevity, our steel structure warehouses provide optimal industrial and commercial storage solutions. The prefabricated steel construction ensures superior durability against harsh weather, heavy loads, and long-term wear.

Customizable in design, these warehouses offer clear-span interiors and adaptable layouts for efficient space utilization. Their modular components enable fast installation, reducing construction time and costs significantly.

With fire-resistant and pest-proof properties, plus minimal maintenance needs, our steel warehouses deliver a cost-effective, sustainable storage solution for logistics, manufacturing, and distribution needs.

On-Site Steel warehouse Installation

Quick-Install Steel Structures | Durable & Reliable for Construction Projects

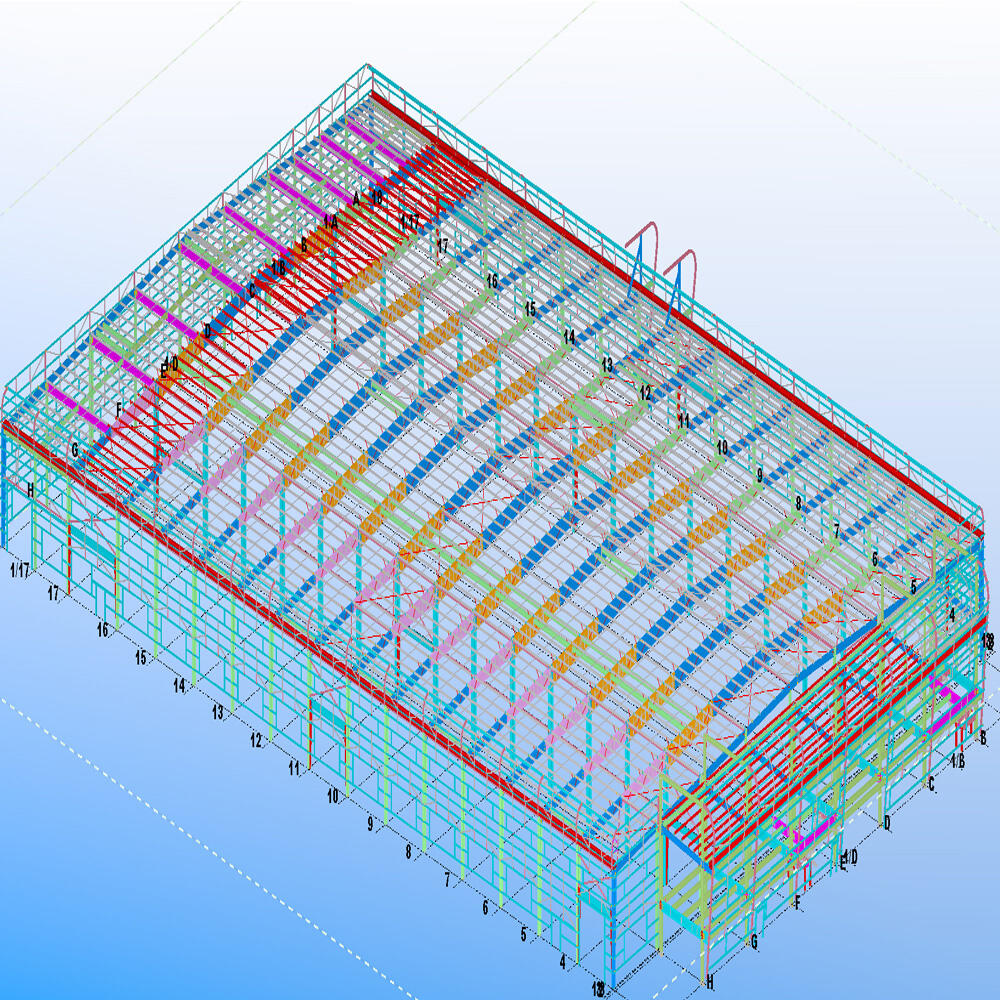

3D Steel Structure Warehouse Model Material Display

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Applications of Prefabricated Steel Warehouses

Our prefabricated steel warehouses are widely used across industries, providing durable, flexible, and cost-effective space solutions for various commercial, industrial, and agricultural needs.

Ideal for grain storage, feed shelters, and farm equipment housing, especially in rural or agribusiness environments.

Offers efficient space for production lines, machinery, and raw material storage, with large clear-span designs that improve workflow.

Perfect for distribution hubs, inventory storage, and packaging areas that require open layouts and easy access.

Used for vehicle repair, equipment maintenance, and custom fabrication, with strong structures built to support heavy-duty operations.

Suitable for wholesale storage, cold chain logistics, and retail distribution centers, ensuring safety and scalability for modern businesses.

Advantages of Prefabricated Steel Warehouses

A). Fast & Easy Installation

Prefabricated steel frames are factory-made for precise, bolt-together assembly, cutting construction time by 50%+ and saving labor costs.

B). Customizable Designs

Expandable clear-span structures adapt to any need—attach to existing buildings or modify later for future growth.

C). Eco-Friendly & Cost-Efficient

Steel’s low maintenance, recyclability, and energy efficiency reduce long-term costs vs. traditional materials.

D).Extreme Weather Resistance

Engineered to withstand hurricane winds (120+ mph), heavy snow loads (1.5 kN/m²), and seismic activity—non-combustible for added fire safety.

E). Less Maintenance Durability

Steel is not prone to warping, cracking, or shrinking, which reduces the need for repairs or replacements. The main steel structure frame life span can reach 50+ year.

Steel Warehouse Fabrication Process:

Steel Structure Building Design Requirements

Design Element |

Description / Options |

1. Building Size |

Length × Width × Height (Height impacts structural design and cost) |

2. Building Usage |

Warehouse, Factory, Workshop, Hangar, Poultry Farm Shed, Industrial Plant, etc. |

3. Insulation Type |

EPS Panel, Glass Wool, Rock Wool, PU Sandwich Panel |

4. Lighting & Ventilation |

Skylights, Roof Vents, Natural Ventilation |

5. Doors & Windows |

Roll-up Door, Sliding Door, Steel Door, PVC Door, Standard or Custom Windows |

6. Wind / Snow Load |

Local wind load (e.g. 120 km/h), snow load (e.g. 1.5 kN/m²), or seismic zone info |

7. Crane Requirement |

Yes / No — If yes, please specify capacity (3T, 5T, 10T, 15T, etc.) |

8. Project Location |

City and Country (affects local climate and building codes) |

9. Surface Treatment |

Painted Steel / Hot-Dip Galvanized for corrosion resistance |

10. Mezzanine / Special Floor |

Mezzanine Floor, Multiple Stories, or Other Custom Requirements |

Contact Us to Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691