Steel Grade : Q235B/Q355B (GB standard)

Application: Steel building

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Steel building

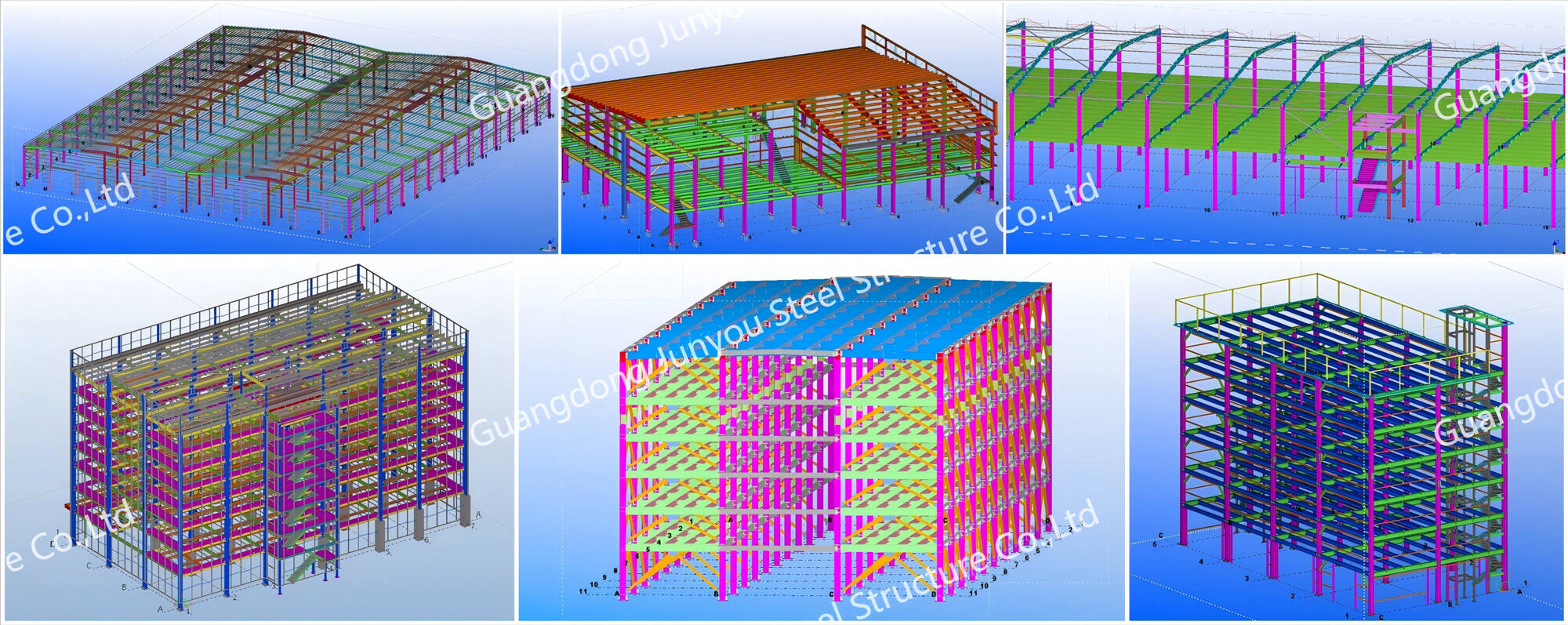

A steel building (also called a pre-engineered metal building or prefabricated steel structure) is constructed with high-strength steel framing, including:

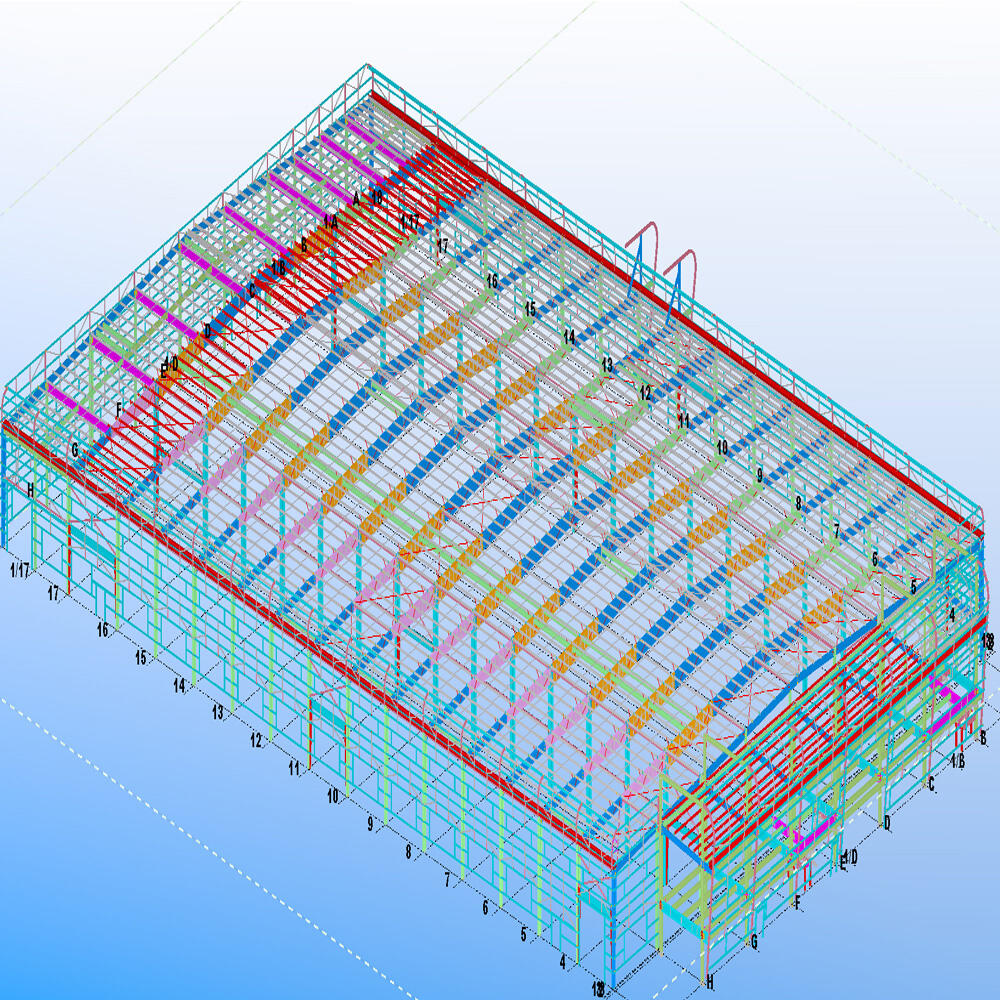

Steel building layout

On-Site Steel Frame Installation

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

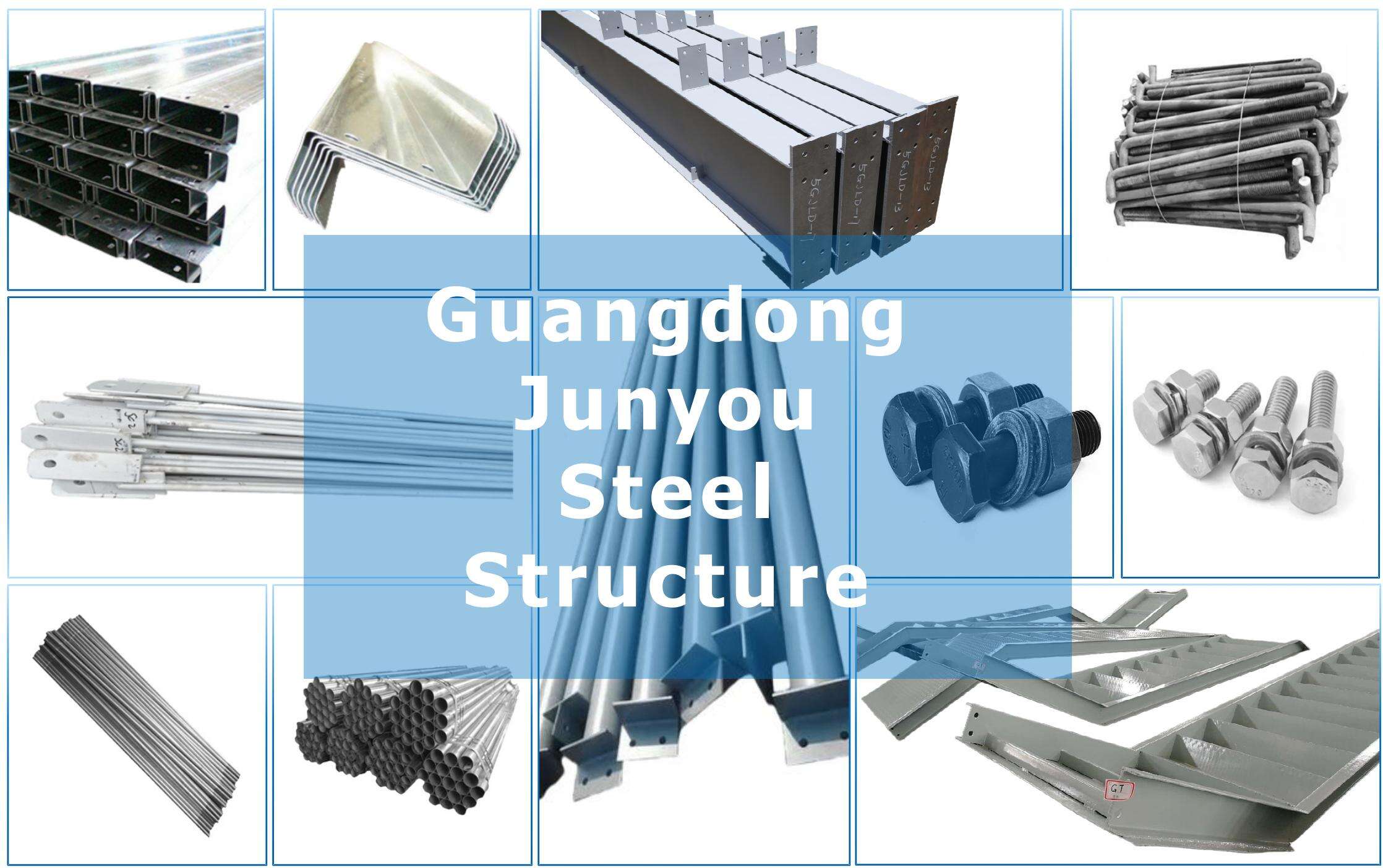

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Key Advantages of Steel Structure Buildings

1. Fast & Efficient Construction

Prefabricated components are manufactured off-site for precision and quality control.

Quick on-site assembly with bolted connections, reducing construction time by 30-40%.

2. Flexible & Customizable Designs

Versatile layouts with clear spans up to 100m+ (no interior columns needed).

Easy expansion & modification – Can be integrated with existing structures or adapted for future needs.Architectural freedom – Supports modern, open-space designs.

3. Cost-Effective & Economical

Lower material costs (20-30% savings vs. traditional concrete/brick construction).

Lightweight steel reduces foundation requirements, cutting costs further. Shorter build time = lower labor expenses and faster return on investment.

4. Extreme Weather & Earthquake Resistance

High strength-to-weight ratio ensures structural integrity. Superior seismic performance (can withstand magnitude 8+ earthquakes). Strong wind resistance – Ideal for hurricane & typhoon-prone regions(≥280km/h).

5. Low Maintenance & Long Lifespan

Corrosion-resistant coatings prevent rust and degradation.No warping, cracking, or pest damage (unlike wood/concrete). Minimal upkeep – No need for frequent repainting or repairs.

Steel building techniques

Steel building techniques include structural design, fabrication, welding, assembly, and installation. That refers to the methods and processes used in the construction of steel buildings. Steel is a durable and robust material that can support large spans and heavy loads, making it suitable for a wide range of construction projects. Steel has strength, versatility, and cost-effectiveness, making it a reliable and long-lasting choice for various applications.

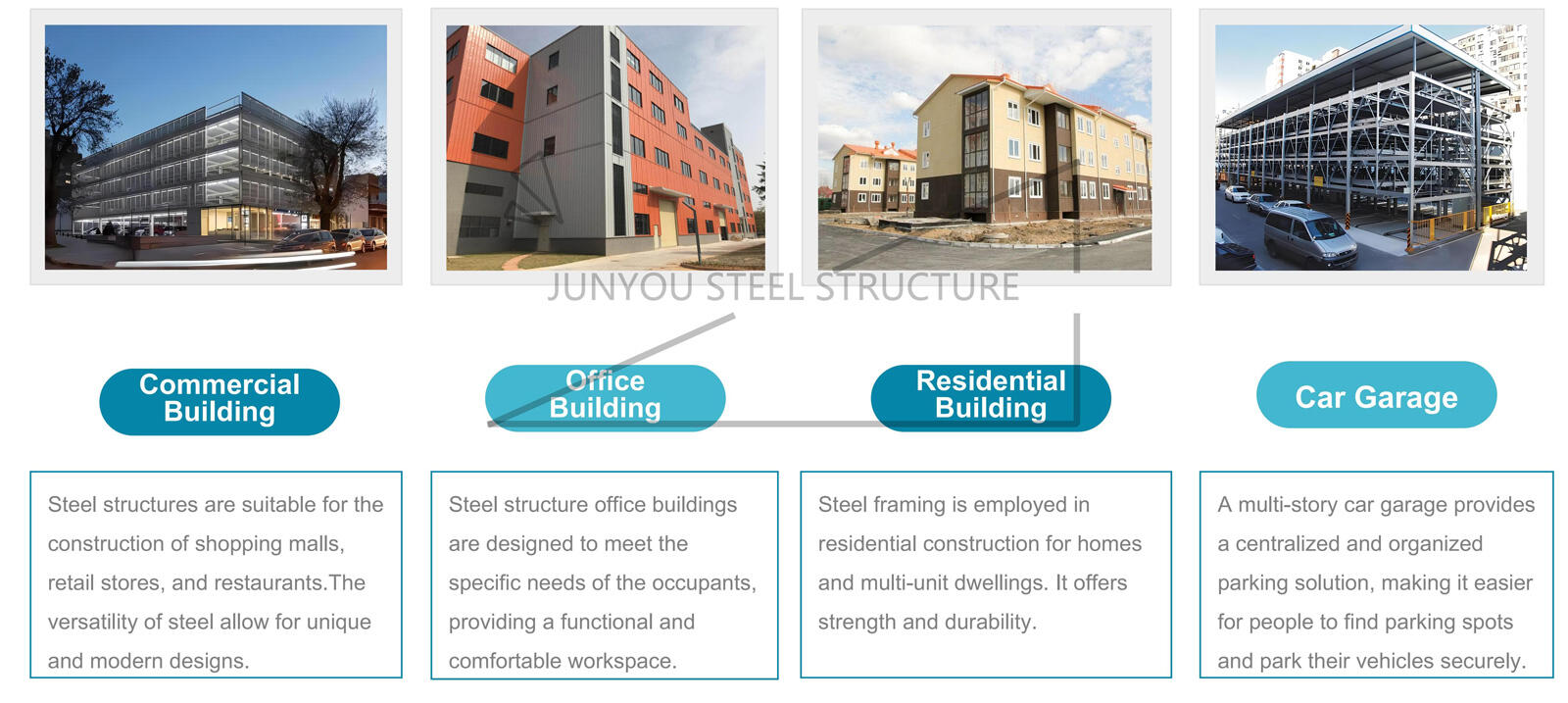

Steel structure building various application

Steel is one of the most widely used building materials in modern construction, offering unmatched strength, versatility, and cost-efficiency. Steel structures are ideal for a wide range of applications, including:

✅ Industrial & Commercial – Workshops, warehouses, storage sheds, shopping malls

✅ Large-Span & High-Rise – Exhibition halls, airport terminals, multi-story buildings

✅ Agricultural & Storage – Poultry farms, grain barns, godowns

Why Choose Us?

(1) A building material sample can be offered for testing if needed.

(2) A free drawing(Floor plan and elevation plan) can offer to give you a rough idea.

(3) Advanced production equipment and skillful workers to ensure on-time delivery.

(4) OEM and ODM orders can be accepted.

(5) Factory visiting is always welcome.

After choosing us

(1) We will offer a Proforma Invoice(PI) for you.

(2) We can arrange the shipment if necessary, because we have a close relationship with some shipping company.

(3) We can accept the third party to check the goods before delivery.

(4) We will ensure on-time delivery.

(5) We will give feedback in every stage of production.

(6) We have a skillful load team that loads containers nicely.

(7) We will offer detailed installation drawing in English to guide the on site assembly work.

(8) If necessary, we can send engineers on-site to guide the installation.

E-mail: [email protected]

Phone: +86-13535848691