Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Workshop

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

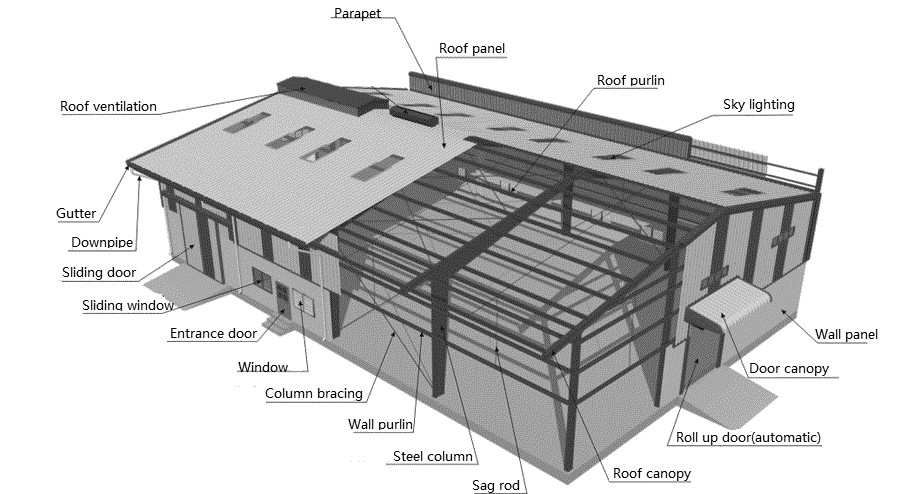

A steel workshop is a prefabricated building designed to provide a reliable and functional space for manufacturing, assembly, or industrial operations. Built with high-quality steel frames and cladding, these structures offer superior strength, longevity, and performance compared to traditional materials like wood or concrete. Steel workshops are highly durable, capable of withstanding heavy-duty use and harsh weather conditions, making them an ideal solution for a wide range of industrial applications.

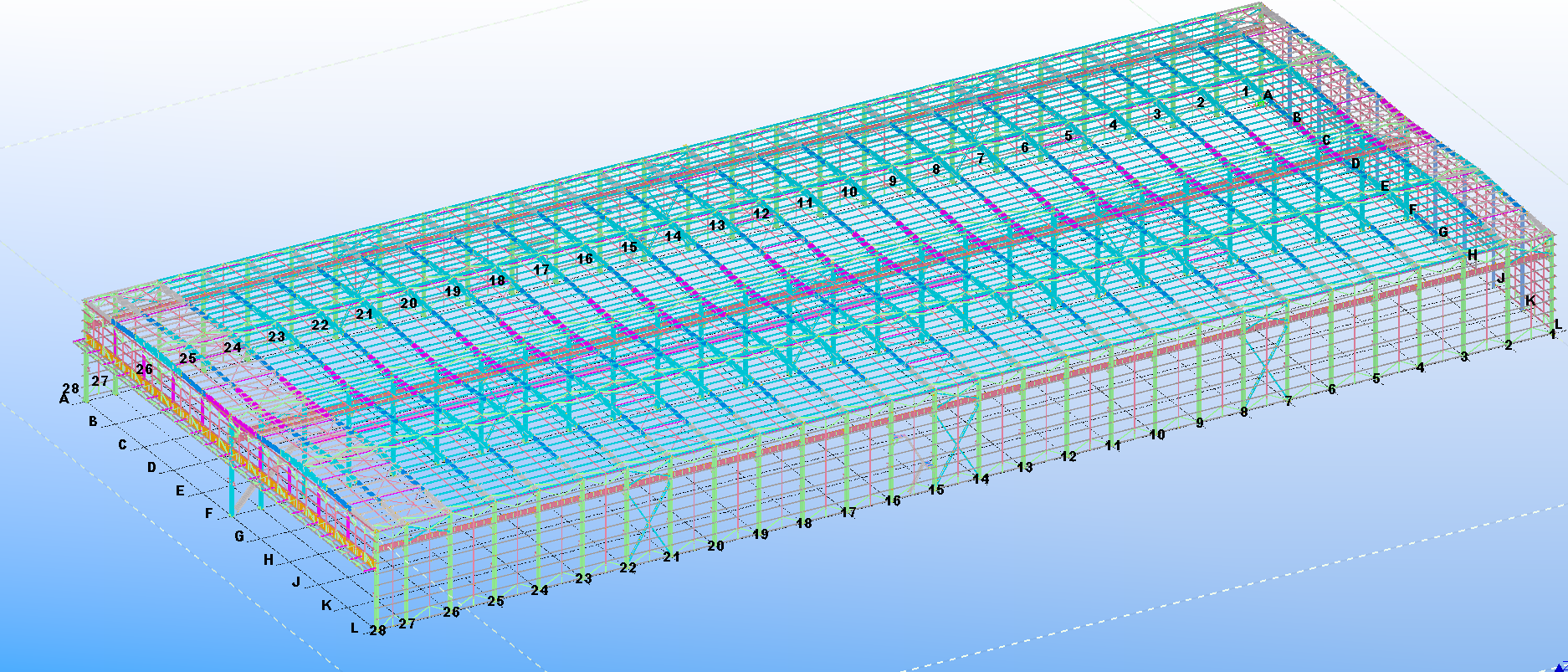

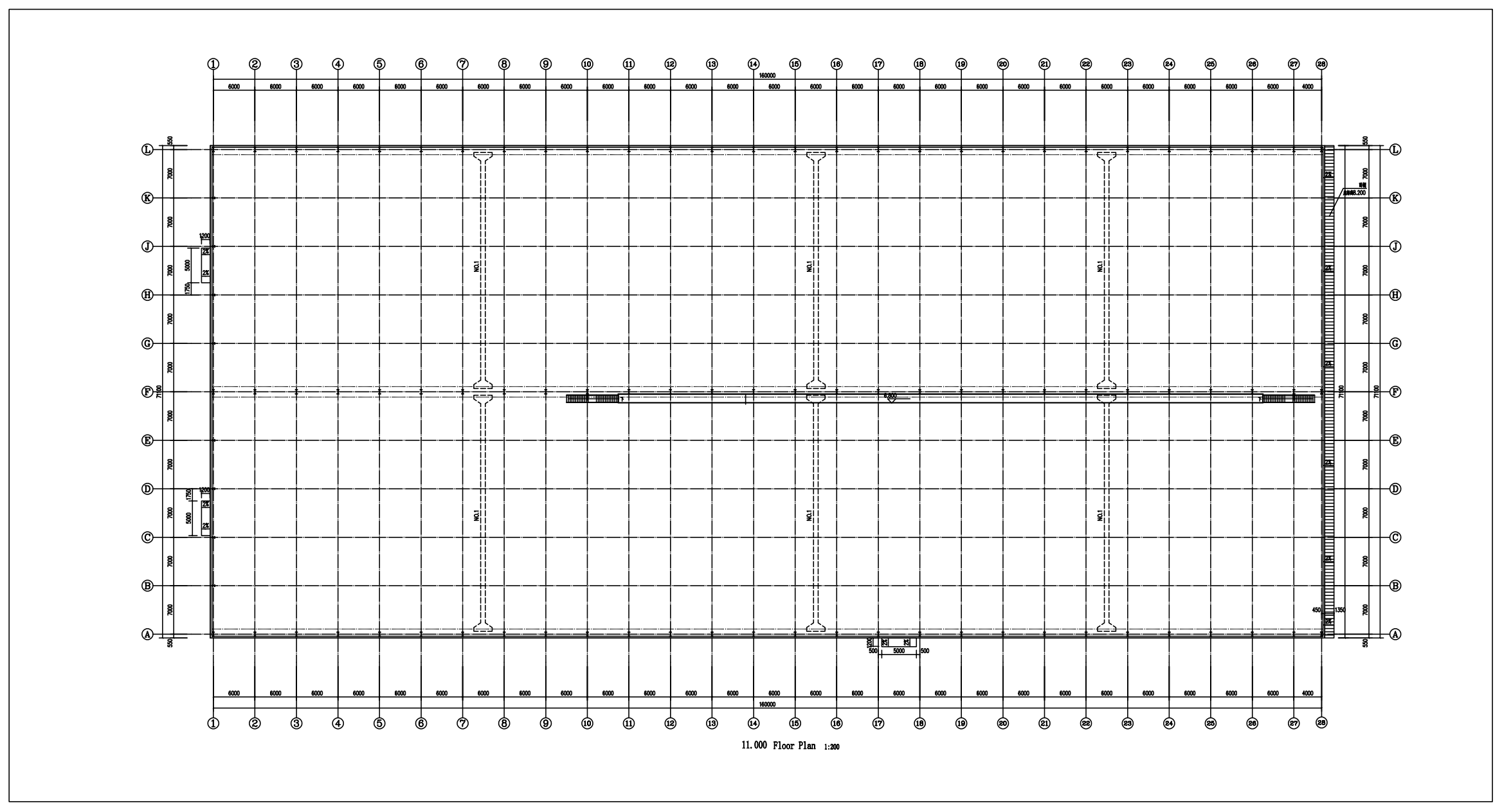

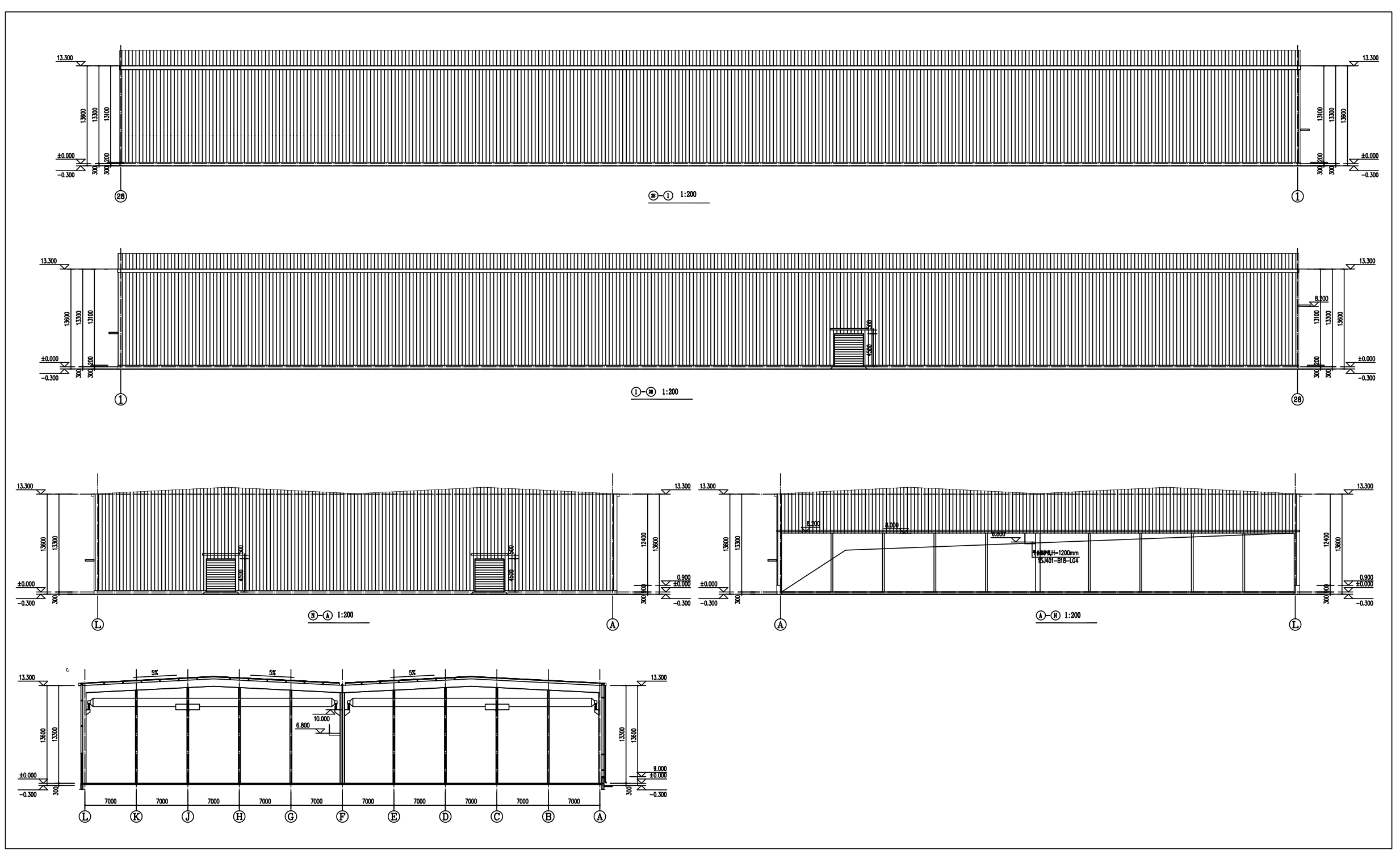

Heavy-Duty Metal Workshop Building – 160.2m x 71m x 13.6m

This large-scale steel workshop building is designed for heavy industrial operations. Built with high-strength structural steel, it offers superior durability, functionality, and customization.

Key Specifications:

This industrial metal workshop is ideal for factories, machinery maintenance centers, or production plants requiring large spans, high clearance, and strong lifting capabilities.

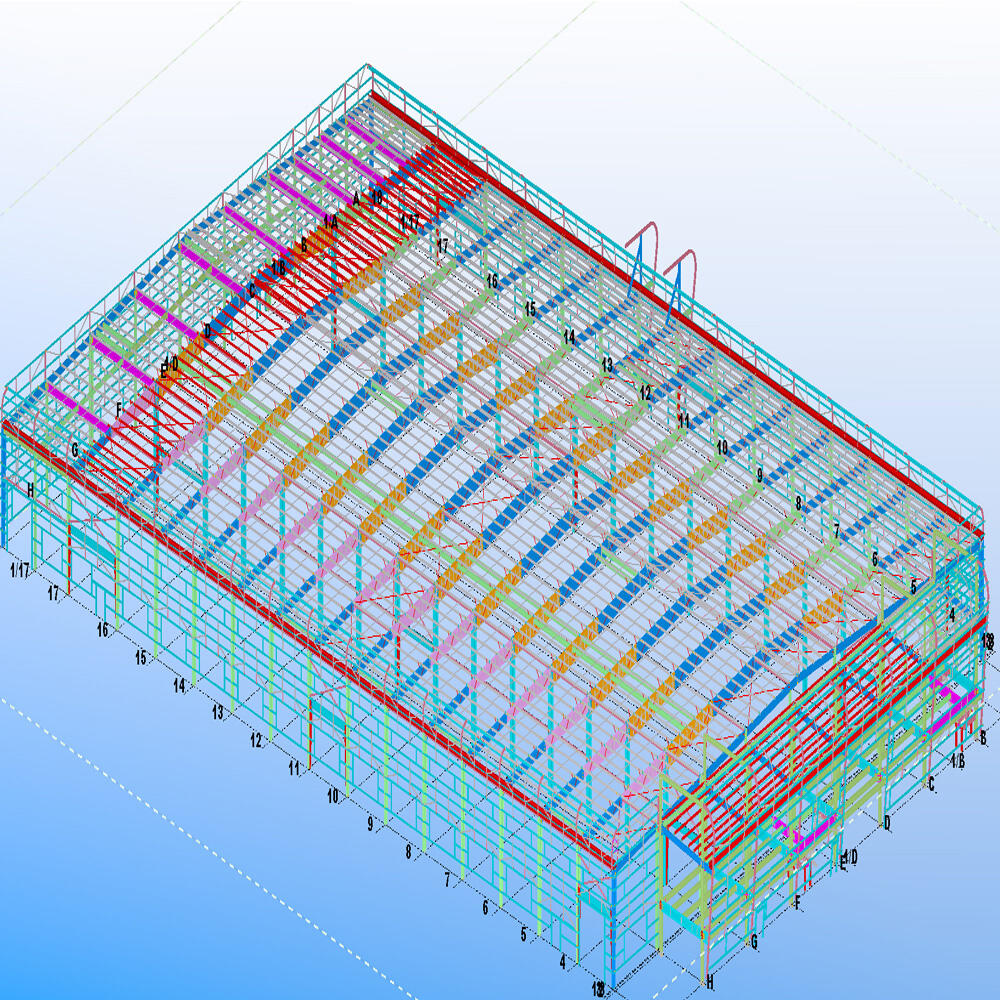

Steel workshop layout

On-Site Steel Frame Installation

Fast Installation. Strong Performance. Real Projects.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Performance Features:

Steel workshop buildings are becoming the preferred choice for industrial and commercial projects due to their strength, speed, and cost efficiency. Here are the main benefits of choosing a steel structure for your next project:

1. Versatile Applications

Steel structures are ideal for a wide range of uses, including factories, warehouses, office buildings, gymnasiums, aircraft hangars, and more. They are suitable for both single-span structures and multi-story or high-rise buildings, offering flexible design options.

2. Fast and Easy Construction

All components are prefabricated in the factory, ensuring precision and consistency. On-site assembly is simple and fast, significantly reducing construction time and labor costs.

3. High Durability with Low Maintenance

Steel buildings are built to last. They resist corrosion, extreme weather, and pests, requiring only minimal upkeep over time—ideal for long-term industrial use.

4. Modern Aesthetic and Custom Design

Steel workshops feature clean lines and a modern appearance. Color-coated wall panels and flexible cladding options allow for customized exterior designs to match your brand or facility style.

5. Cost-Effective Building Solution

Thanks to their lightweight structure, steel buildings reduce foundation costs. Combined with faster construction and lower maintenance, the overall economic benefit of steel structures often surpasses traditional concrete buildings.

Steel workshop application

Fully Customizable Steel Workshop Buildings to Match Your Operational Needs

Every steel workshop building we provide is fully customized to meet the unique requirements of each client. From building size and internal layout to essential features like overhead cranes, ventilation systems, and thermal insulation, everything is tailored to support your production goals.

By investing in a custom steel structure workshop, businesses can create a dedicated, well-organized space that enhances workflow efficiency, boosts productivity, and supports long-term industrial growth. That’s why more and more companies are choosing to build steel structure factories—they’re reliable, scalable, and designed for performance.

Steel Workshop Fabrication Process:

FAQ

Q1: What industries commonly use steel workshops?

A: Steel workshops are widely used in manufacturing, warehousing, automotive repair, agriculture, aviation hangars, and sports facilities due to their strength, flexibility, and durability.

Q2: Can steel workshops be customized for specific applications?

A: Yes. Steel workshops can be tailored with features like overhead cranes, insulated walls, specialized doors, and ventilation systems to meet unique operational needs.

Q3: How fast can a steel workshop be constructed?

A: Because most components are prefabricated in factories, steel workshops can typically be installed on-site within a few weeks, saving time compared to traditional construction.

Q4: Are steel workshops suitable for harsh weather conditions?

A: Absolutely. Steel structures are designed to withstand extreme weather, corrosion, and heavy loads, making them ideal for a variety of climates.

Q5: What are the cost benefits of using steel workshops?

A: Steel workshops offer lower foundation costs, faster construction times, and minimal maintenance, providing excellent return on investment over concrete or wood buildings.

Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691