Steel Grade: Q235B/Q355B (GB standard)

Application: Steel workshop

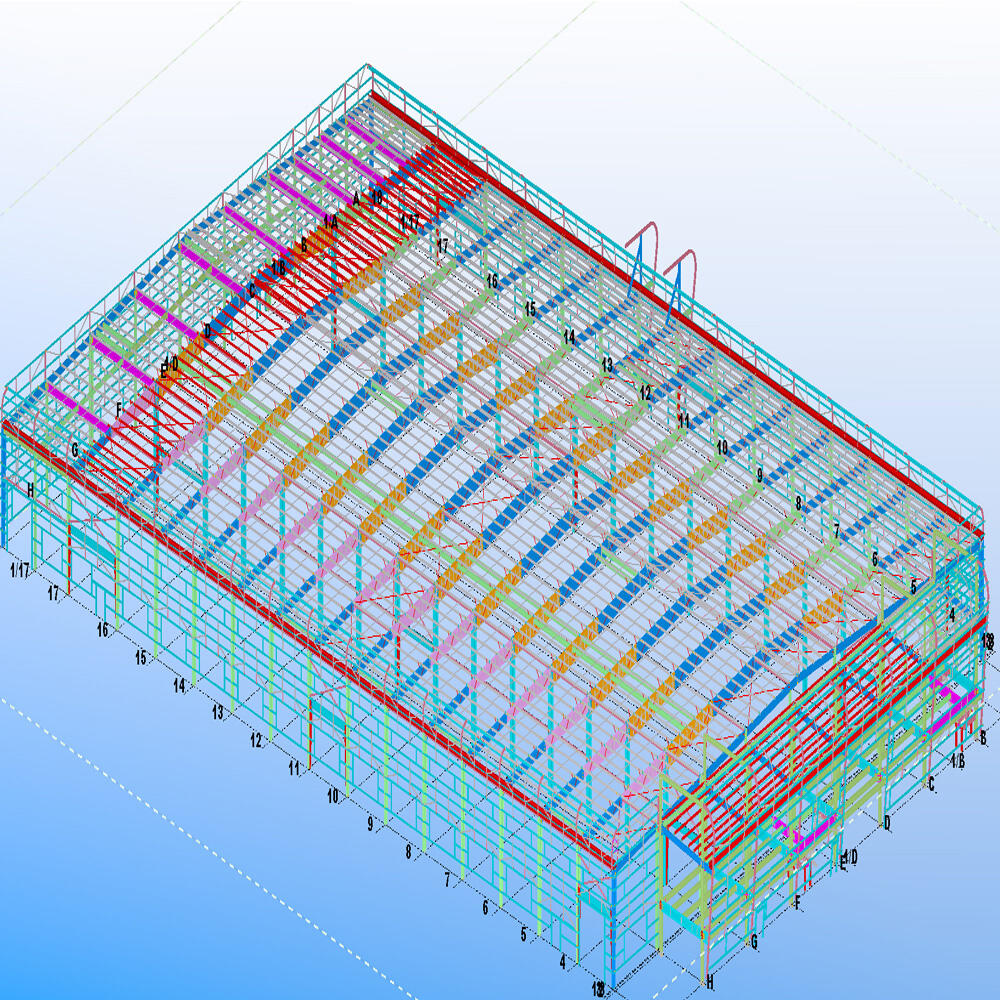

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

A prefabricated steel structure workshop is an efficient and eco-friendly solution widely used in industrial, agricultural, and commercial buildings. All major steel components—such as beams, columns, and roof trusses—are pre-engineered and fabricated in the factory, then transported to the construction site for bolt-based assembly, greatly reducing labor costs and construction time.

Thanks to its fast installation, minimal on-site waste, and recyclable steel materials, this type of workshop is also considered environmentally friendly and compliant with modern green building standards.

Custom Prefab Steel Workshop Solutions

We offer fully customized insulated steel workshops tailored to your project needs. Options include single-span or multi-span layouts, with a maximum clear span of up to 40 meters—all without the need for central support columns. Whether you're building a large-scale industrial facility or a compact agricultural workshop, we can provide the right steel solution for you.

On-Site Steel Workshop Installation

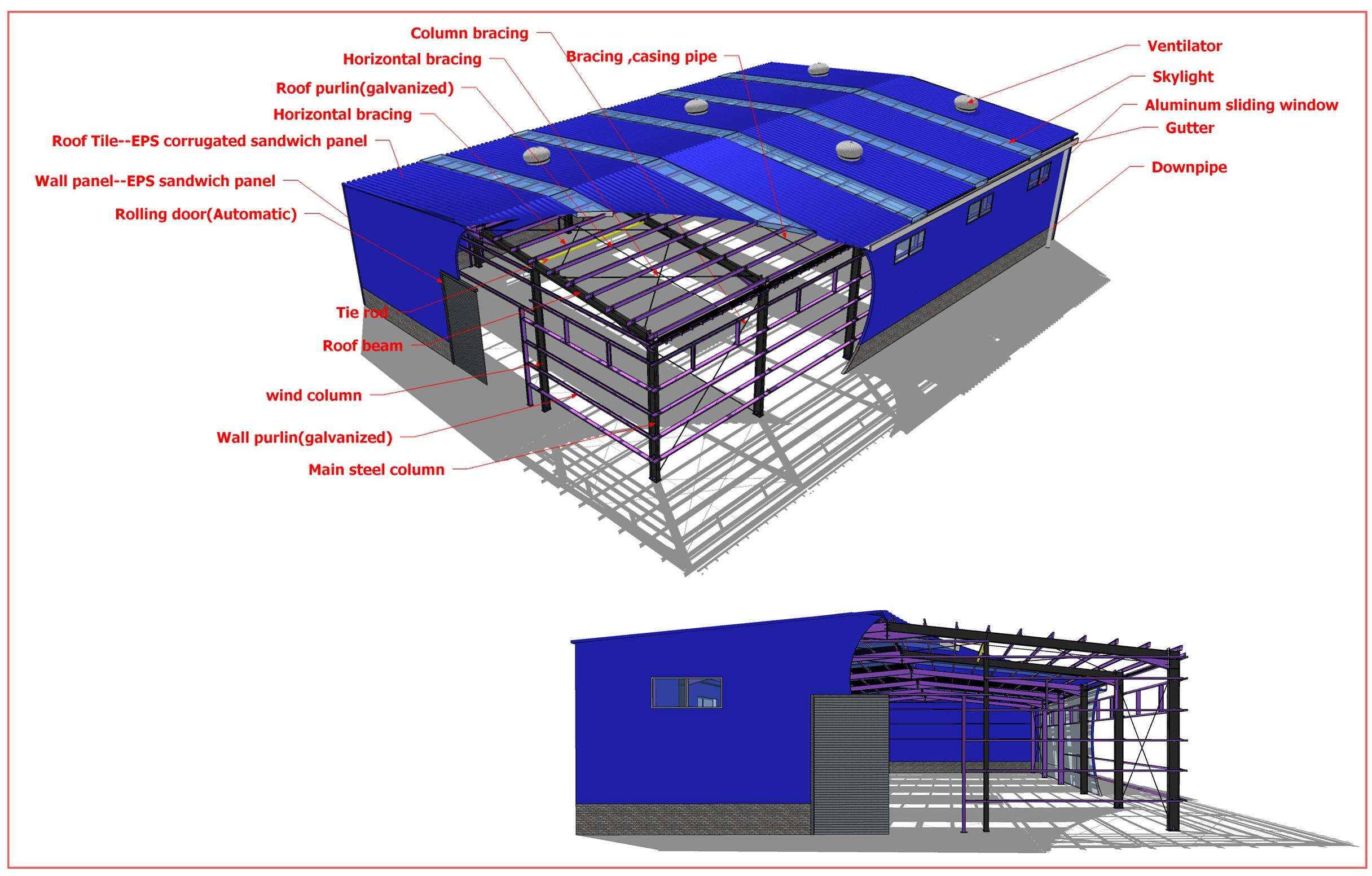

The construction details for steel structure workshop:

1.Embedded parts

These components are used to securely attach the steel structure frame and provide a strong foundation for the building.

2.Columns

Made of H-section steel, the columns offer vertical support to the structure, ensuring stability and structural integrity.

3.Beams

H-section steel or I beams are commonly utilized for beams. The height of the intermediate area is determined based on the beam span, ensuring proper distribution of loads.

4.Purlins

C-purlins and Z-purlins are typically employed to support the walls and roof. These elements provide horizontal support and help evenly distribute the load across the roof.

5.Bracing

Round steel is commonly used for supports and braces, providing additional stability and reinforcement to the structure.

6.Roof and wall panels

There are two commonly used panel types. The first type is corrugated steel sheets, also known as color bone steel sheets. The second type is insulated sandwich panels, which consist of a layer of insulation (such as EPS, Glass wool, Polyurethane, or rock wool) sandwiched between two layers of color-coated sheets. These panels offer thermal insulation, soundproofing, and fire protection, ensuring durability and protection against weather elements.

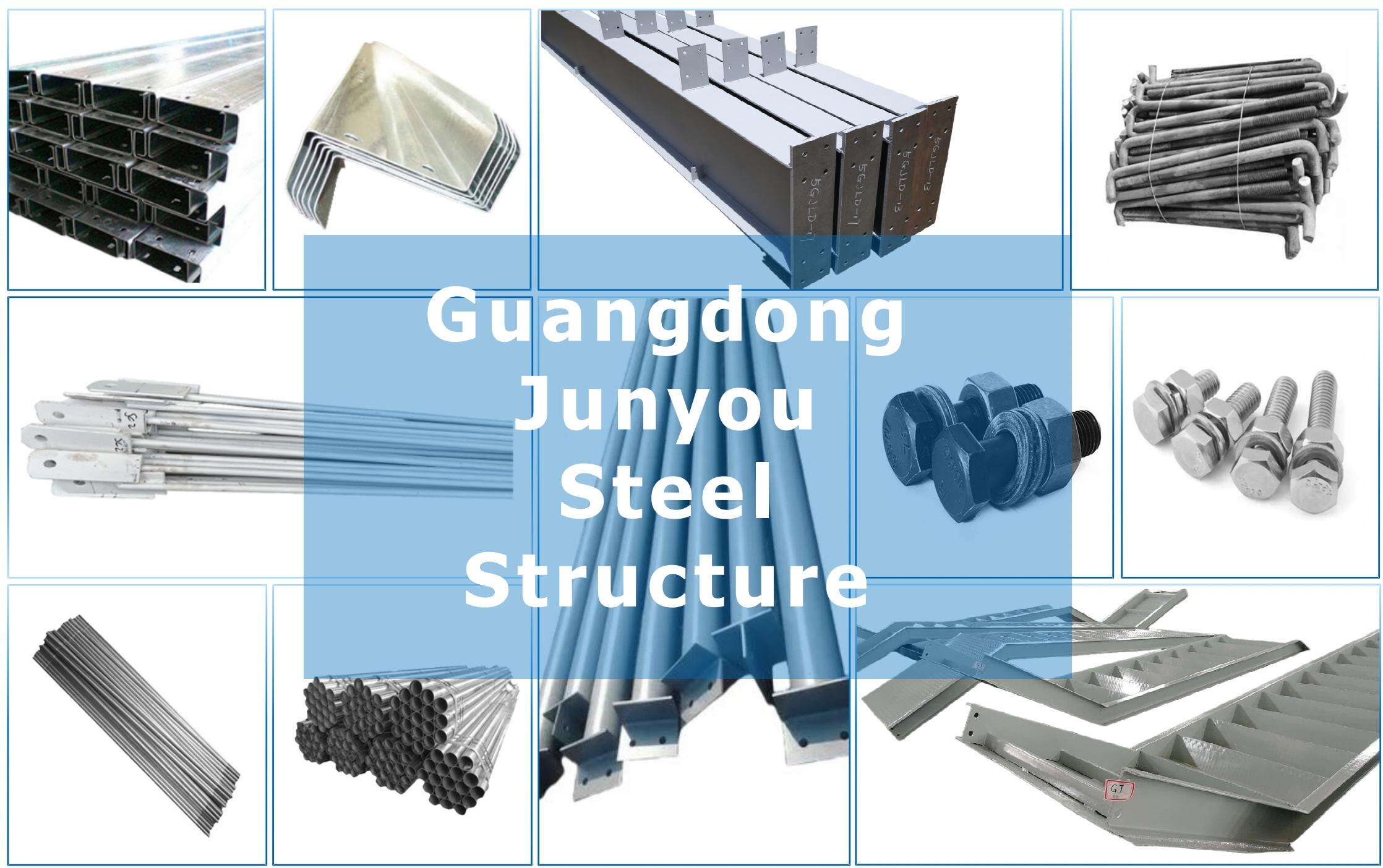

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Steel structure building application

It has various applications in construction, including commercial buildings, warehouses, workshops, storage sheds, aircraft hangars, industrial facilities, agricultural structures, poultry farms, chicken houses, barn sheds, sports arenas, and residential buildings, etc. Steel's versatility allows it to be used in a wide range of projects, providing strength and durability in different settings.

Benefits of Steel Structure Workshop

1. Fast and Easy Installation

All steel components are pre-fabricated in the factory and precisely cut to size, allowing for quick on-site assembly with bolts. This reduces installation time, labor costs, and the need for complex fabrication work.

2. Flexible and Expandable Design

Steel buildings offer versatile layout options. They can be easily connected to existing structures or expanded later to meet changing project requirements—ideal for growing industrial or commercial needs.

3. Cost-Effective and Eco-Friendly

Steel is a durable, recyclable material that reduces construction time and long-term maintenance costs. Its energy-efficient design can also help lower utility bills over the building’s lifespan.

4. Resistant to Harsh Weather

Steel structures are built to withstand extreme weather conditions, including high winds, heavy snow, earthquakes, and fire. Steel’s high strength-to-weight ratio makes it both safe and structurally reliable.

5. Low Maintenance Requirements

Steel is resistant to corrosion, pests, and warping, and doesn’t require frequent painting or sealing. With minimal upkeep, steel buildings offer long-term performance and cost savings.

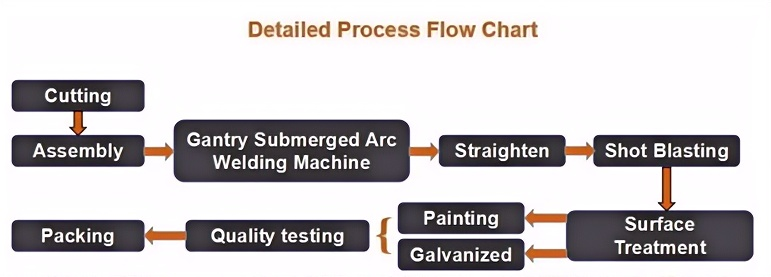

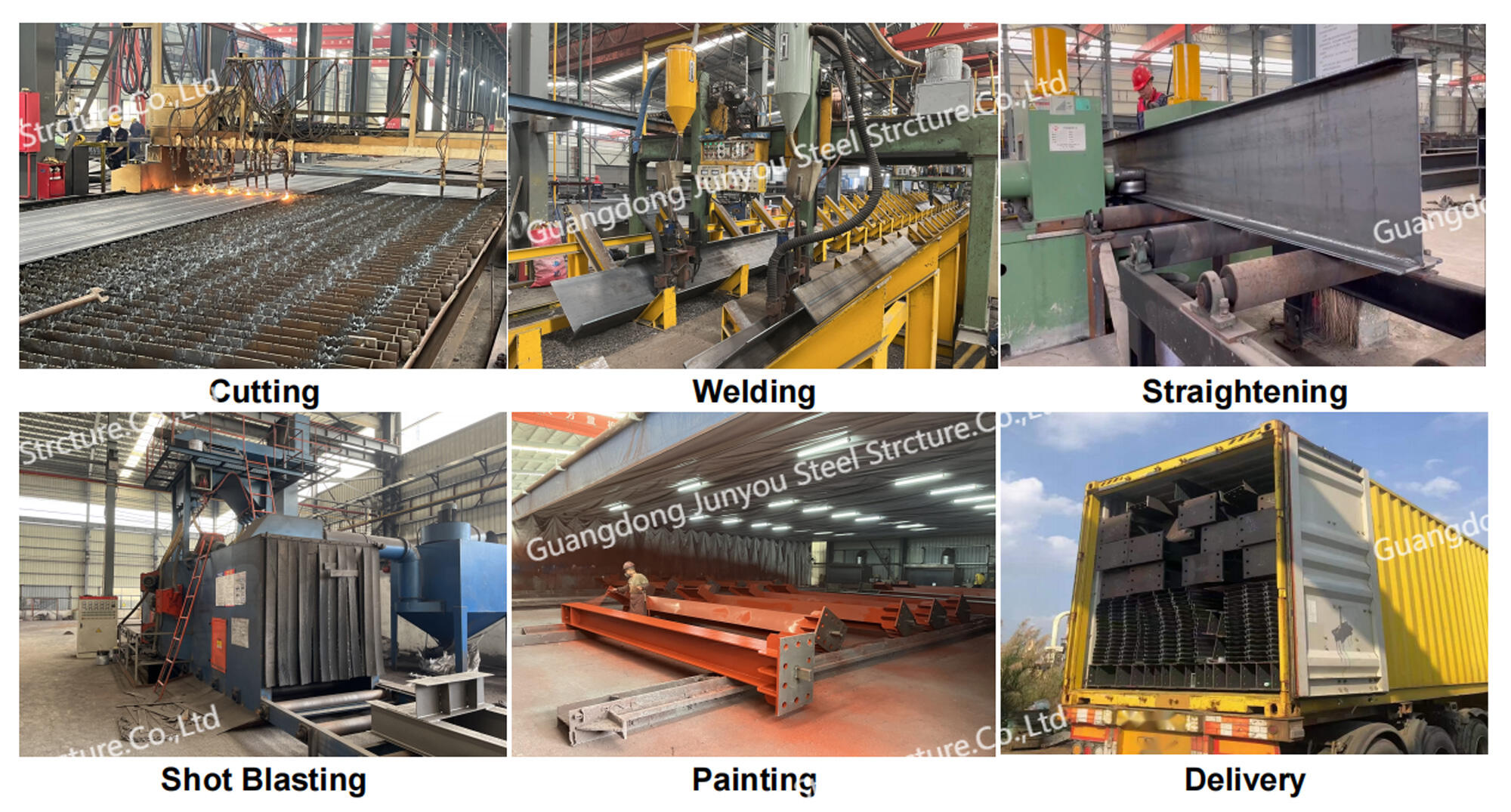

Steel Workshop Fabrication Process:

Get Your Tailored Steel Workshop Quote Today! - Faster Build, Lower Costs, Sustainable Results!

E-mail: [email protected]

Phone: +86-13535848691