Kii Ṣe Iwakọ Ifa Ilẹ Poju Iru Aṣeyọri

Iwakọ ifa ilẹ n peye orisirisi iru aṣeyọri ni ipoju, nitori awọn iṣẹ to wà láti inú ilẹ ati awọn ọna ti a tún padà. Iwakọ yìí ko gba ibatan ti o daju bi igi tabi ilẹ.

Lilo iwakọ ifa ilẹ ati awọn ibatan ti o fa idiwọ

Awọn nkan ifa ilẹ ti a kọja sẹyin ti a fi han ninu iṣẹ, ko si ibatan ti o daju bi ilẹ. Awọn agbata gbé àkọsílẹ ati àkọsílẹ tí a kọja sẹyin sinu èto, nigba ti awọn bọtini yipada iwakọ alailowọ. Iwakọ yìí fa ọsẹ 4–6 kọja awọn iṣẹ ilẹ ti o wà (Raputa Iṣẹ Ilẹ 2024).

Ìgbésẹ: ifa ilẹ tàbí ìgbésẹ aṣeyọri

| Àwòrán | Ifa Ilẹ | Ìṣe-ayika | Waktu ti a gbe l'ore |

|---|---|---|---|

| Iwakọ Ilẹ | ọjọ 7 | 14 days | 50% |

| Iwakọ Ibi | ọjọ 18 | 45 days | 60% |

| Igbagbara Ọsùnwọ | ọjọ 2 | 14 days | 85% |

Ìmọ̀ dídájọ́: ìpamọ̀ àkókò tí ó jẹ́ kuru lóríṣìiríṣìi ilé ti a ṣe pẹ̀lú àdẹ́kun kan

Àwọn iṣẹ́ tó n lo àdẹ́kun kan ti wáyé 34% sisi julọ nígbàdí tí wọn ba n ṣe ilé alágbára, báyìí kí á sọ nínú ìwé-ìriri tí ó pín 127 ohun elo ilé (Allied Buildings, 2024). Àwọn ilé kólọ̀ tó ṣe irinṣẹn dára ju, wọ́n ti rí ìmudara pínpín, pàápàá jùlọ nípa 50% nígbàtí wọn ba fi irinṣẹn láàyè gbogbo.

Ṣe iyara tuntun jẹ́ kanna pé o dara? Gbígbé iyara pẹ̀lú àṣeyọrí ilé

Nígbàtí àkókò tí ó sunwọ̀n yara ba funni fún ẹ̀tọ́, ìdásílẹ̀ àkókò jẹ́ káàbọ̀. Àwọn idiwòn inaakoko tí ó dára láàyè ti ojú-aláìní ìdánilẹ̀kọ̀ sí iṣẹ́ méjìlé kan mú kí ohun èlò báyàrà àwọn ibeere wọn bí àti láìní kúnrẹ. Ìdíjẹ́ kíkọ àdẹ́kun kan máa pa aláìní ìdánilẹ̀kọ̀, ó sì tàǹ báyìí iyara ati iyipada láàyè gbogbo.

Irinsẹn ati Ohun Eto Módùlù Tó N Nípa Iyara Nínú Ifamọra Àdẹ́kun Kan

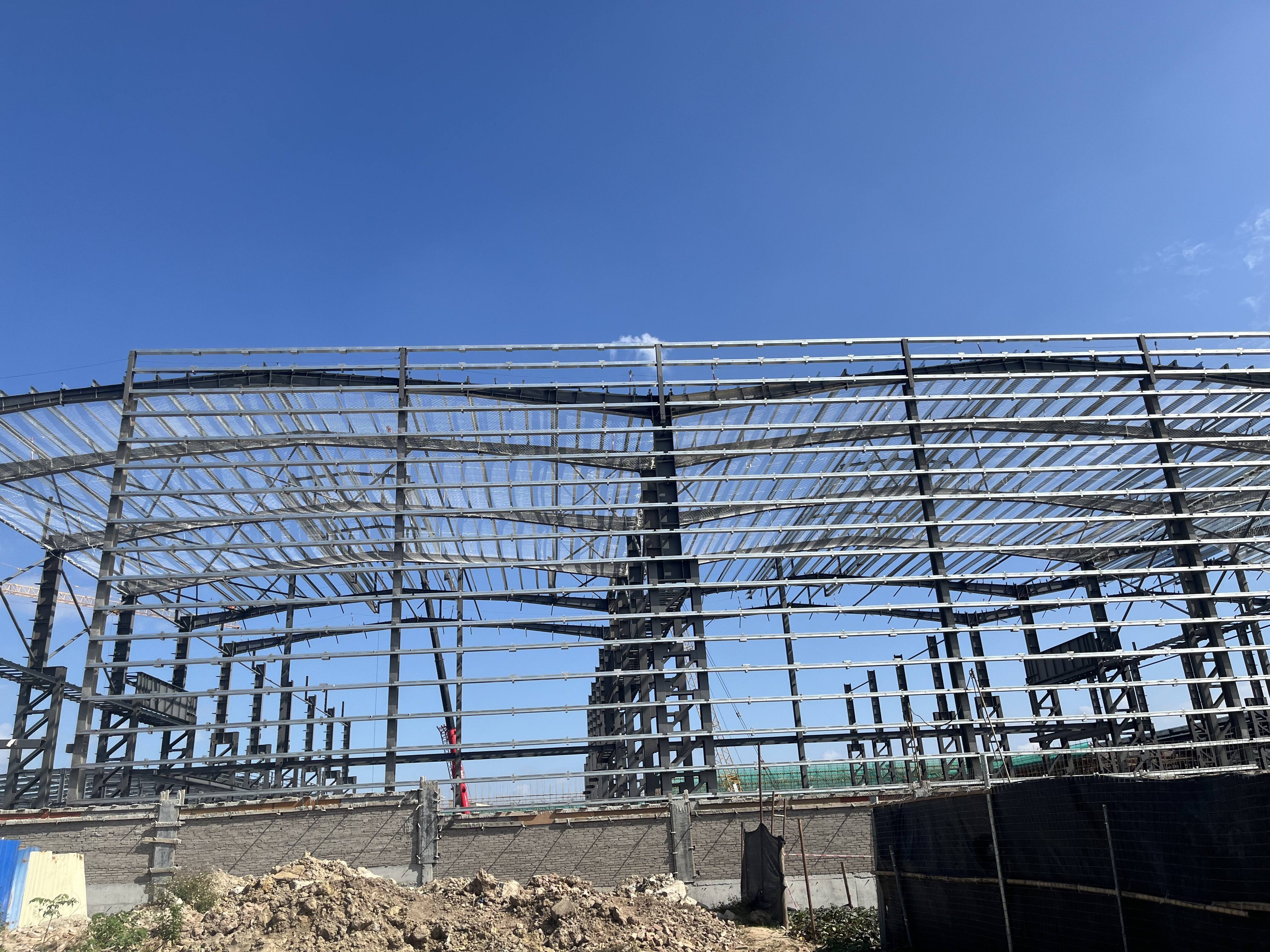

Ifamọra Láàyè Ojú-Aláìní Ti Awọn Ohun Eto Pre-Engineered Steel Ati Ise Wọn Nínú Ifamọra Tí Yara

Ìtọ́nta àfàrà sílìndà ní ẹ̀ka ìdìbò sílìndà jẹ́ kí o ṣe àwọn ọ̀nà láìsí iṣẹ́ nígbà tí wọn ti ṣe lára wọn pẹ̀lú àkópọ̀. Àwọn bẹ́ẹ̀mù, àwọn olórí, àti àwọn ọ̀nà tẹtrẹ́ẹ́káàdòótá wọ̀nyí ṣe wọn nínú àwọn ilé-ìṣẹ́ nípa lilo àwọn ọmọ àtúnṣe tó ṣe àwọn inú sílìndà pẹ̀lú àkópọ̀ dínà 2mm bí ó tilẹ̀ rí ní ọ̀nà àtúnṣe ilé 2023. Ilé-ìṣẹ́ kò yẹ kí wọn sọnsọǹ nípa omi òrùn tàbí arùn ara, èyí tó dáa láti pa àwọn ohun èlèmílẹ̀rìnpọn sí 18% láàárín tí wọn bá ti ṣe àwọn ohun nípojì. Nígbàtí àwọn ohun tí a ti ṣe tẹlẹ̀ wá sí iho iṣẹ́, wọ́n jẹ́ ohun tí a le lo kádí kádì, tó máa pa àwọn akoko tí ó yẹ kí a lo fún àwọn idiwọn tí a máa ṣe nígbà tí a ba farapamọ̀. Gbogbo iṣẹ́ idiwọn yìí yìí kúrù pàtàkì nípa 40%.

Ìtànààwọ̀n ohun tí a ti ṣe tẹlẹ̀ sílìndà sípojì sí iho fun ìfagilẹ́

Ìpílẹ̀yìn ilé iṣòro tó dáa ṣe é kí àwọn ọgàn ọja ní ìgbàlèlé tí ó jẹ́ kọ̀nkrìtì náà wá síbẹ̀ láti inú kí wọ́n sì fún wọn nígbà tí wọ́n bá yẹ. Àwọn ibúsùdára nla ti ń lo láti gbe àwọn ọgàn tí ó tobi yìí wá lónìí, nítorí àwọn èrò pàtàkì tí ó dáa tó ti ṣe é kúrò nínú àwọn igbesẹ̀ tó báyìí ní odò orílẹ̀-èdè báyìí ní oju kíkọ̀ kan. Láìgbà wá sí abẹ, àwọn crane ti ń gbé àwọn ọgàn módùlù náà jade pẹ̀lú àwọn ìdálẹ̀ tó dáa—nígbàdí, 500 square meters ní òjì niyèkè kan—tí ó dáa ju ohun tí a ṣe ní ìdámúlàyé kọ̀nkrìtì ní oju mẹ́ta lọ. Iye ohun kíni tí ó ṣiṣẹ́ dáa náà máa jẹ́ kí àwọn aláṣẹ kọ̀mọ́ kíkọ̀ kéré sí, kí wọ́n sì kún irinrajé kéré sí láti gbigbèràn àwọn ọgàn tó kò yẹn báyìí nígbà tí àwọn iṣẹ́ ti ń dídá.

Ipo: Kíni Bí Iwulo Módùlù Ti ń Pọ̀ Sí Nínú Àwọn Iṣẹ́ Steel Tó Pọ̀ Jù Lórílẹ̀-èdè

Sílẹ́ jẹ́ àwọn ọjọ́ tó yìí ní Global Construction Survey láti 2023, àbò ọ̀kan nínú mẹ́tãàdùn aráwọn olùṣáré ti bẹ̀rù kọ̀ ìgbésí ayé fàámù irin módùlù nínú èyí tí ó wà lórí mẹ́tàdínláàdùn ọ̀nà. Kí ló mú kí àwọn ohun kan yi ngbérò? Ọ̀pọ̀lọpọ̀, ó ṣèdìntà àwákọsí ilé iṣẹ́ nídeede ní ọ̀kan nínú èjì, ó sì lè dín kikún láàdùn-ọ̀kan dé láàdùn-ẹjìde nígbà tí ó ńkópa àwọn idàmúra tí ó wà ní ọ̀nà mẹ́tàdínlá. Àwọn olùṣáré orílẹ̀-èdè ni yàn kíkọ̀ ohun kan yi gan-an nítorípẹ̀ àwọn ilú jẹ́ alága pẹ̀lú àwákọsí. Ohun kikọ̀ àtúnse jẹ́ kò lé mọ́rá láìka ìrírí àwọn inú ilé àti àwọn ìbéèrè àrùn tí ó wà nígbàgbọ́.

Kíkọ̀ Onsite Títun: Ìdíntà Kíkọ̀ àti Ìdínu Ilé Iṣẹ́

Ìdíntà Kíkọ̀ Ojà àti Bímù Látàrí Àwọn Oniṣe Tí Wà Pẹ̀lú

Àwọn oniṣe títọ́ọ́ tó wà pẹ̀lú yọ kikún onílèfẹ̀ àti dá intà kíkọ̀. Àwọn igbàràlẹ̀ ní ọjọ́ kan tó ní àwọn bràkẹ́tì títọ́ọ́ àti àwọn ibùbún bolted jẹ́ kóǹkúrò ìgbésẹ̀ 35–50% títun níyèyè oríṣìṣí tó ti wá welding (Applied Engineering 2023). Èyí tó n dára kó pàtàkì àdánwò àti ìgbàlódé, ó sì fún àwọn olùṣẹ̀ lókàn pátápátá nígbàtáwọn àkọdára tuntun.

Ìdànjúlè láti mú ìdásílẹ̀ àwọn ìlòkàn tuntun láìbò lèhìn

Ìdànjúlè àwọn ohun èlò nípa ìgbàlódé tó tẹ̀lẹ̀ nígbàtáwọn ìlòkàn irin:

- Àwọn olùlùṣẹ̀ ìlùṣẹ̀ níṣẹ́jú ìlòkàn akọkọ nílo GPS-gùídé alignment

- Ìlòkàn alágbàrà tó kùnrin níṣẹ́jú níṣàlẹ̀ nígbàtáwọn ìlòkàn àkọkọ

- Ìlòkàn welding tó kùnrin níṣẹ́jú nígbàtáwọn ìlòkàn tó kùnrin

Ìgbàlódé tó kùnrin yìí n tó àkókò tó kùnrin nígbàtáwọn ìgbàlódé, pàtàkì tó kùnrin nígbàtáwọn ìgbàlódé tó kùnrin 4–6 ìlòkàn tó kùnrin nígbàtáwọn ìgbàlódé nígbàtáwọn ìgbàlódé tó kùnrin.

Ìdànjúlè tó kùnrin nígbàtáwọn ìlùṣẹ̀ àti ìgbàlódé tó kùnrin nígbàtáwọn ìlòkàn irin

Lati kọ ọlọpọnna kan ni pato, a nilo iṣeto alakowe ti o baamu si amunimura ti ara ẹni. Awọn apẹrẹ tuntun han pe awọn ibora ti a fọwọsi ti n lo ifijiṣẹ lẹsẹkẹsẹ ti awọn ọgbanje irin naa jẹ:

| Àwòrán | Iye iyara julọ nigba laarin Ohun Gidi |

|---|---|

| Osho ọlọpọnna | ipari 62% |

| Iwulo olugbin | idaabobo 40% |

| Awon ibudo aisai | kejìdehin-ọgọrun 28% kere si |

Awọn iṣelọpọ ti o tọ pẹlu awọn ibora alagbeka ti a ko ni digitaali le sunmọ akoko ti kikọ irin naa ni ọsù 3–5 ni awọn iṣẹ oniwe. Awọn idajọ wo yii wuwo ni igbesi aye ti ibora ti inu ile-alakoja lati dinku awọn idasilẹ ti o ṣanpa akoko nibẹ.

Ìdániléèwò Àkànṣe àti Àwọn Ohun Èlò Díkítálì fún Ìmúṣẹ Àpapọ̀ Àwọn Àpèsè

Ṣíṣe àtẹ̀lé ètò àtẹ̀lé ètò tó kún fún ìsọfúnni nípa àwọn ìpele ìfúnni àti ìgbéga irin

Ipele irin ti a ṣe ni a le pari nipa 22% yiyara pẹlu awọn iṣe iṣeto ti o dara, bi a ti fihan ninu iwadii tuntun lati Ile-iṣẹ Iṣakoso Iṣelọpọ pada ni ọdun 2024. Bí wọ́n bá ti ń gbé àwọn ohun èlò náà dé ní àkókò tó yẹ, tí wọ́n sì ní àwọn ẹ̀rọ tó ń gbé e, tí wọ́n sì ní àwọn òṣìṣẹ́ tó ń ṣiṣẹ́ níbẹ̀, ìyẹn á jẹ́ kí wọ́n lè máa ṣiṣẹ́ dáadáa. Àwọn alágbàṣe tí wọ́n ti gba àwọn ètò ìtòlẹ́sẹẹsẹ 4D ti ilọsiwaju wọ́n máa ń ní ìdẹ̀yìn tó dín kù ní ìdá 15% nítorí pé gbogbo nǹkan máa ń lọ́nà dáadáa. Bí àpẹẹrẹ, gbé ohun èlò tó ń mú kí ìmọ́lẹ̀ máa tàn jáde. Nígbà táwọn òṣìṣẹ́ bá ṣètò àwọn iṣẹ́ yìí pa pọ̀ pẹ̀lú àkókò tí wọ́n fi ń mú kọ́rọ̀ ṣe, wọ́n máa ń dín ìjákulẹ̀ kù tó nǹkan bí ìpín mẹ́rìnlélọ́gọ́rin nínú ọgọ́rùn-ún, tó bá fi wé àwọn ọ̀nà tí wọ́n ti Àwọn ètò ìsọfúnni inú àwọsánmà òde òní ti wá ṣe pàtàkì gan-an, wọ́n ń jẹ́ kí àwọn òṣìṣẹ́ lè ṣe àtúnṣe sí àwọn ètò wọn lójú ẹsẹ̀ nígbà tí ojú ọjọ́ bá ṣàdédé ṣẹlẹ̀ tàbí tí àwọn tó ń pèsè nǹkan bá níṣòro láti pèsè àwọn ohun èlò.

Igbalẹ̀ ọrukọ ọwọ́ ọgbọn ilé (BIM) láti tọ́ àtúnṣe ìpínlẹ̀ káríèsì inú ìdásílẹ̀

Ìgbalẹ̀ BIM yọrí ara ìmúdára pẹ̀lú 40% nínú àwọn ìdásílẹ̀ ilẹ̀-ìwé, bí ó ti wàásù nínú Ọmótì AEC 2023. Agbejoro ona rẹ yoo han ara oju ona ibamu meji laisi iwa se idagbasoke, lati yo awọn idasilẹ ti o wa ni ile alabara. Awọn oludasa ti o lo aworan BIM sunmo ilé-ìwé 18% ju si lopin nipasẹ:

- aworan 3D ti awọn ijinna isopọ

- Idaniloju ikilọ ikilọ bolt-hole ti o dara julọ

- Ìtọ́ntà ilàkàn ohun èlò (tó yọrà ìfọwọsowopo pẹ̀lú 12%)

Àwọn ìdásílẹ̀ tí ó ní BIM títí yóò gba 97% ìdánwò ìmúdára nínú àwọn àwòrán ilé-ìwé.

Ipa ti ìmúdára ilé-ìwé ati ìwé-ìmúdára nínú yiyatọ awọn idasilẹ ati awọn idagbasoke ni ile alabara

Ìjọba àtúnàròyìn tó tọ́ga nípa 30% (Steel Construction Institute, 2024) nípa ìfọwọsí àdánù ilẹ̀ktròníkù nípa àtúnàrí ìdánwò ìlọsiwaju. Àwọn àkọsílẹ̀ tọ́ga nípa ìdánilẹ́kọ̀ síbẹ̀rẹ̀ pẹ̀lú àwọn ibi tí a ti ṣàtọ́ nípa àwọn ibi tí a yẹ kọja, nípa ìyara ìdánilẹ́kọ̀ nígbà ti o wà ní ilẹ̀. Àwọn olùṣòfìn tí wọ́n n lò àwọn àtúnàrí ìlọsiwaju tó ṣàbẹ̀rẹ̀ yiyọ 25% kọ̀yàfà kíkà àwọn RFIs nígbà ti o wà ní ilẹ̀ bí àwọn tí wọ́n n lò àtúnàrí àkọsílẹ̀.

Àwọn Ìbẹlẹ àti Ìrọlùwà nípa Ìgbàlódé Ìgbéjáde Ìlẹ̀ktròníkù

Ìgbéjáde ìlẹ̀ktròníkù ṣẹlẹ̀ nípa àwọn ìbẹlẹ títùn tó ṣẹlẹ̀ nípa ìgbàlódé àwọn ìṣẹ́. Àwọn ìdarí tó ṣàtọ́ nígbà àti àwọn ìdarí tó ṣàtọ́ nígbà ti o wà ní ilẹ̀ ṣẹlẹ̀ nípa àwọn ìṣẹ́ tó ṣàtọ́ nígbà, nípa àwọn ìṣẹ́ tí ó ṣẹlẹ̀ 30% kọ̀yàfà nígbà tí o wà ní ilẹ̀ nídá bá àwọn ónà tí wọ́n n lò nípa ìdarí tó ṣàtọ́.

Ìdánilẹ́kọ̀ Kọ̀yàfà àti Ìrọlùwà Nípa Ìgbàlódé Ìgbéjáde

Ìgbéjáde tó ṣàtọ́ ṣẹlẹ̀ nípa ìdarí tó ṣàtọ́, pàápàá ní àwọn ibi tí ó ní ìdánilẹ́kọ̀. Àwọn ìṣẹ́ tí wọ́n n lò nípa ìlẹ̀ktròníkù ṣẹlẹ̀ $18–$32 kọ̀yàfà nígbà tí o wà ní ilẹ̀ nínú ètò ọrọ orisunrisin bí a ti máa pa ìdájọlọ sí iṣẹ́ kíkúrúkúrù tàbí ìtúnṣe.

Àpẹrẹ Ogun Olópin: Síríṣí Àmìwòrán Láàárín Mẹ́fà Ọ̀sẹ̀ nípa Lilo Igbé Sílíndà

Olúpojú ilé wọlé sìí dá àmìwòrán sí ọgọ́rùndá mẹ́wàá pẹ́lú ohun elo igbé sílíndà tí a ti ṣètò, ó sì tọ́nta iyara ọwọ́ láàyè báyìí ní $210,000 (Ilé-Ẹkọ BuildSteel ). Àníkan yi ojú kíka pé bí ó ṣe dáa lórí inu ìdájọlọ tí ó se nípa ìdájọlọ nínú ọwọ́ ọjà ilé.

ROI gan-an ati Idánimọ̀ọlá Ailayipo nínú Awọn Iṣẹ́ Adijere ati Awọn Iṣẹ́ Ilé-Iṣẹ́

Awọn olùdásílẹ̀ àti awọn olùṣárẹ̀ le ṣe idánimọ̀ọlá ilé wọn ọ̀sẹ̀ mẹ́jìdínláàárín mẹ́fà lọ́jàádáyẹ̀bọ̀ tí kò lé mọ́. Ìdíni igbé sílíndà náà sì tọ́nta ètò ìtúnṣe láàárín ọdún 19%, bí a ti rí nínú àwòfàájọ ọjà 2024.

Àwọn àwùjọ FọọKù

Kí ni àwọn ẹ̀gan pínpín ti ilé igbé sílíndà?

Ìdásílò ohun èèyàn lórí àdáṣe ohun ìmù jinlẹ̀ nípa ìgbà kíkọ̀ tó yara, ìwọn gbigbèrè kan tàbí ara ẹni kóra, ati ifarapa ilẹ̀ tó dáa ju ọna aláìní ayé kọ.

Kí ló dá sí ìdásílò ohun èèyàn lórí àdáṣe ohun ìmù jinlẹ̀ yara ju ọna aláìní ayé kọ?

Ìdásílò ohun èèyàn lórí àdáṣe ohun ìmù jinlẹ̀ ní oúnjẹ́ àtúnse tí wọ́n ti ṣàdéhùn títí, ó sì tọwọ́n idìbò ayé àti ìgbà fún un láàrin ìdásílò ohun ìmù jinlẹ̀.

Bawo ni àtúnse àwọn nǹkan ṣèyàtọ̀ sí ìgbà kíkọ̀?

Àtúnse àwọn nǹkan máa ń darí bí wọ́n ti ṣeeṣe ní àwọn ilana tí ó dára, ó sì fún lẹ́sán sí ìkópa àti ìdíntò nǹkan ní gbólójú kíkọ̀.

Ṣe o wà nǹkan tí ó dánimọ̀ràn pé ó le jẹ́ kí a lò ohun èèyàn lórí àdáṣe ohun ìmù jinlẹ̀?

Bẹẹni, àwọn iṣẹ́ tí ó lò àdáṣe ohun èèyàn maa nǹkan wà nǹkan tí ó kóra, ó sì lè rí iye tí ó túnba lọ nítorí ìgbà kíkọ̀ tó kúrò àti ìwọn kekere ti a ba se àtúnse lẹ́hin kíkọ̀.