| Availability: | |

|---|---|

| Quantity: | |

Product Information

Prefabricated steel structure buildings are generally completed by a series of steel structures, including steel columns, steel beams, purlins, etc. Steel is a popular choice today because using it can construct different shapes and specifications buildings.These main components form the load-bearing structure of the building.

These steel structures are reliable and require less raw material than some other types of structures such as the common traditional concrete brick wall buildings and timber buildings, because of their high strength characteristic.Due to its light weight and easy construction, it is in great demand in the industrial, agricultural and commercial fields. Steel structures are also the most cost-effective type of construction for many projects.

Generally, for all steel structure projects, we recommend that customers build a little brick wall at the bottom of the wall. The bricklaying at the bottom of the external wall of the steel structure can waterproof, reduce the erosion of moisture, and avoid the damage of water to the wall, so as to ensure a longer service life of the building.

The product we display here is an industrial workshop building made by Q355B H beam as the main steel frame and corrugated steel sheet for the wall and roof, this project has a 3m brick wall. The windows are installed on the brick wall, which has a better load-bearing effect than the color-bone steel sheet and must be stronger. And last but not least, after the brick wall is decorated, it will be nicer than the steel sheet.

Project picture display:

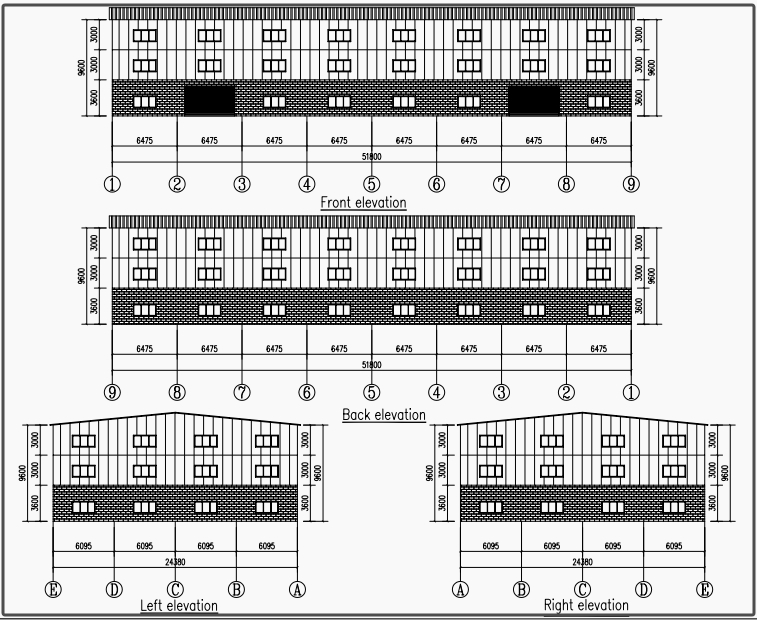

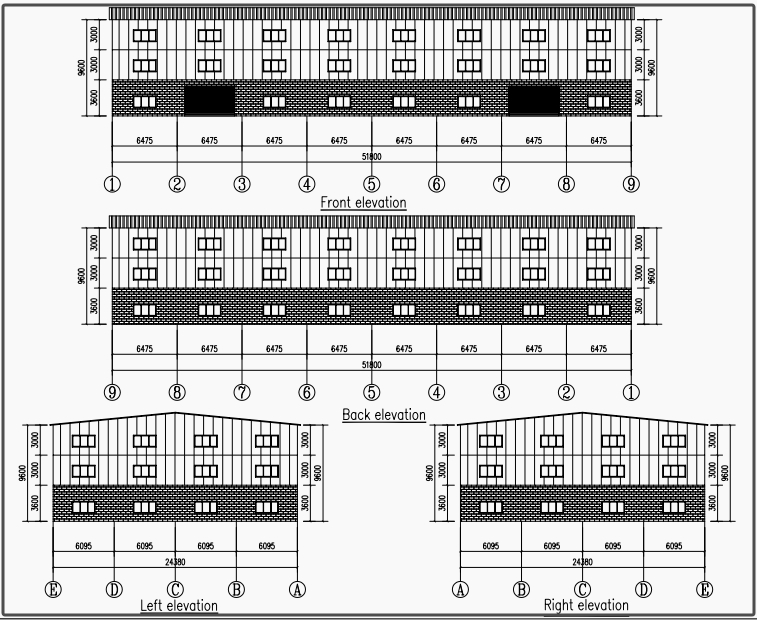

Project drawing display:

Steel building advantage:

Statistically speaking, steel is one of the most commonly used building materials in modern construction overall. Steel structures are used for almost every type of construction, including heavy industrial workshop, warehouse building, storage shed, multi-story residential buildings, high-rise shopping malls, large-span exhibition hall, airport terminals, poultry farm, grain barn, godown etc.

1. High-strength steel material, the main steel structure frame design life span can last more than 50 years;

2. Steel portal frame structure uses H Beam and I beam to make wind resistance, snow resistance, and earthquake resist design;

3. Hot dip Galvanize and paint the structure frame for options to meet the different needs for anti-rust whether close or not close to the sea.

4. Maximize the use of indoor space, clear span can reach 40m;

5. Roof and wall cladding insulation & single steel sheets are both available to match different kinds of client budgets.

6. Bolt assembly without on-site welding can speed up the installation work. This can save time and labor costs during installation.

7. Customized steel building appearance design to fit a certain local or a specific company brand.

Steel building type:

A.Factory

B.Warehouse

C.Workshop

D.Storage

E.Agriculture barn

F.Repair/Mechanic Shop

G.Poultry farm

H.Office Space

I.Residential apartment

Steel structure various application

Steel buildings have various applications in construction, including commercial buildings, warehouses, industrial facilities, agricultural structures, sports arenas, and residential buildings. Steel's versatility allows it to be used in a wide range of projects, providing strength and durability in different settings.

Technical Parameters

I | Main steel frame | |||

1. | Steel structure frame | Welded H steel | Q235B/Q355B | Painting/Hot-dip galvanized |

2. | Wall/Roof purlin | C/Z steel | Q235B | Galvanized |

II | Bracing Part | |||

1. | Tie Rod | ∅89/114/158 | Q235B | Painting/Hot-dip galvanized |

2. | Flexible Bracing | ∅16/18/20 | Q235B | Painting/Hot-dip galvanized |

3. | Sag rod | ∅20 | Q235B | Galvanized |

4. | Brace Rod | ∅32 | Q235B | Galvanized |

5. | Knee-brace | L50 | Q235B | Painting/Hot-dip galvanized |

III | Roof & Wall Part | |||

1. | Roof /Wall panel | Steel sheet | 0.326~0.7mm corrugated steel sheet | |

Insulated sandwich panel | EPS,Glass wool/Rock wool/PU insulated | |||

2. | Roof/Wall trimming | Ridge roof panel | 0.4~0.5 mm steel sheet | |

Flashing | 0.4~0.5 mm steel sheet | |||

Gable wall trimming | 0.4~0.5 mm steel sheet | |||

Wall corner trimming | 0.4~0.5 mm steel sheet | |||

IV | Window & Door part | |||

1. | Window | PVC/Aluminum frame | Single/double glazing (Fixed/sliding/swing) | |

2. | Door | Rolling/sliding door | Automatic and manual method | |

V | Accessories | |||

1. | Bolts | Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud | ||

2. | Gutter | Steel sheet/galvanized/Stainless steel(304) | ||

3. | Downpipe | PVC 110/160 | ||

4. | Roof Ventilator | ∅600 (Galvanized) | ||

Quotation service:

A. If you have the drawings

We can provide you with the full service of production, shipment and

Installation guide, which is high quality and low cost.Because we own all kinds of technical facilities, complete test instruments, and advanced production processes.

B.No drawings provide us for the follow information

1. The specifications for the steel building do you need? (Length, width, and height, the height of the building can big affect the cost)

2. What is your steel building used for? (factory, workshop, warehouse, hangar, plant, poultry farm shed, etc.)

3. Thermal conditions of your steel building. (EPS, glass wool, rock wool, PU)

4. The lighting conditions of your steel building. (Ventilation/skylight)

5. The window and door requirements. (roll-up door/sliding door/steel door/ PVC door)

6. The wind-load/ snow load for your steel building. (to design a safe structure that can withstand the weather conditions)

7. Does The steel building have a crane or not? (3/5/10/15 ton)

8. Project location.

9. Surface treatment : Paint or hot dip galvanized.

10. how floors? Any mezzanine? or Other special demand.

If you are not about what type or what needs you have regarding you're warehouse/workshop, or this project is your first one. Don't worry, we will offer suggestion for you to choose the right style and the best design within your budget.

Why Choose Us?

1. Our people

Our engineers are very professional, and most of them have more than 10 years of experience in the architecture field.

Our work staff have steel structure processing excellent skills. Some of them even have overseas installation experience.

Our colleagues in the sales team are all passionate about their work and honest and humble towards our customers. Every inquiry or email will be replied to in time. Every question will be paid high attention.

2. Our service

We offer recommendations for our customers in the pre-sale stage.

We offer floor plans, elevation plans, and quotations for free.

We offer construction drawings, and calculation sheets to help you get a construction permit after the order is confirmed.

We offer detailed foundation and Installation drawings after delivery.

We offer details packing lists for every container when loaded so it will be easier to check and get the materials. Form A, Form E, and CO certificates are available.

3. Our advanced processing facilities

We possess more than 10 sets of large precise and domestically advanced processing equipment, including large gantry planing machines, automatic submerged arc welding machines, assembling machines, shot blasting machines, etc.

Product Information

Prefabricated steel structure buildings are generally completed by a series of steel structures, including steel columns, steel beams, purlins, etc. Steel is a popular choice today because using it can construct different shapes and specifications buildings.These main components form the load-bearing structure of the building.

These steel structures are reliable and require less raw material than some other types of structures such as the common traditional concrete brick wall buildings and timber buildings, because of their high strength characteristic.Due to its light weight and easy construction, it is in great demand in the industrial, agricultural and commercial fields. Steel structures are also the most cost-effective type of construction for many projects.

Generally, for all steel structure projects, we recommend that customers build a little brick wall at the bottom of the wall. The bricklaying at the bottom of the external wall of the steel structure can waterproof, reduce the erosion of moisture, and avoid the damage of water to the wall, so as to ensure a longer service life of the building.

The product we display here is an industrial workshop building made by Q355B H beam as the main steel frame and corrugated steel sheet for the wall and roof, this project has a 3m brick wall. The windows are installed on the brick wall, which has a better load-bearing effect than the color-bone steel sheet and must be stronger. And last but not least, after the brick wall is decorated, it will be nicer than the steel sheet.

Project picture display:

Project drawing display:

Steel building advantage:

Statistically speaking, steel is one of the most commonly used building materials in modern construction overall. Steel structures are used for almost every type of construction, including heavy industrial workshop, warehouse building, storage shed, multi-story residential buildings, high-rise shopping malls, large-span exhibition hall, airport terminals, poultry farm, grain barn, godown etc.

1. High-strength steel material, the main steel structure frame design life span can last more than 50 years;

2. Steel portal frame structure uses H Beam and I beam to make wind resistance, snow resistance, and earthquake resist design;

3. Hot dip Galvanize and paint the structure frame for options to meet the different needs for anti-rust whether close or not close to the sea.

4. Maximize the use of indoor space, clear span can reach 40m;

5. Roof and wall cladding insulation & single steel sheets are both available to match different kinds of client budgets.

6. Bolt assembly without on-site welding can speed up the installation work. This can save time and labor costs during installation.

7. Customized steel building appearance design to fit a certain local or a specific company brand.

Steel building type:

A.Factory

B.Warehouse

C.Workshop

D.Storage

E.Agriculture barn

F.Repair/Mechanic Shop

G.Poultry farm

H.Office Space

I.Residential apartment

Steel structure various application

Steel buildings have various applications in construction, including commercial buildings, warehouses, industrial facilities, agricultural structures, sports arenas, and residential buildings. Steel's versatility allows it to be used in a wide range of projects, providing strength and durability in different settings.

Technical Parameters

I | Main steel frame | |||

1. | Steel structure frame | Welded H steel | Q235B/Q355B | Painting/Hot-dip galvanized |

2. | Wall/Roof purlin | C/Z steel | Q235B | Galvanized |

II | Bracing Part | |||

1. | Tie Rod | ∅89/114/158 | Q235B | Painting/Hot-dip galvanized |

2. | Flexible Bracing | ∅16/18/20 | Q235B | Painting/Hot-dip galvanized |

3. | Sag rod | ∅20 | Q235B | Galvanized |

4. | Brace Rod | ∅32 | Q235B | Galvanized |

5. | Knee-brace | L50 | Q235B | Painting/Hot-dip galvanized |

III | Roof & Wall Part | |||

1. | Roof /Wall panel | Steel sheet | 0.326~0.7mm corrugated steel sheet | |

Insulated sandwich panel | EPS,Glass wool/Rock wool/PU insulated | |||

2. | Roof/Wall trimming | Ridge roof panel | 0.4~0.5 mm steel sheet | |

Flashing | 0.4~0.5 mm steel sheet | |||

Gable wall trimming | 0.4~0.5 mm steel sheet | |||

Wall corner trimming | 0.4~0.5 mm steel sheet | |||

IV | Window & Door part | |||

1. | Window | PVC/Aluminum frame | Single/double glazing (Fixed/sliding/swing) | |

2. | Door | Rolling/sliding door | Automatic and manual method | |

V | Accessories | |||

1. | Bolts | Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud | ||

2. | Gutter | Steel sheet/galvanized/Stainless steel(304) | ||

3. | Downpipe | PVC 110/160 | ||

4. | Roof Ventilator | ∅600 (Galvanized) | ||

Quotation service:

A. If you have the drawings

We can provide you with the full service of production, shipment and

Installation guide, which is high quality and low cost.Because we own all kinds of technical facilities, complete test instruments, and advanced production processes.

B.No drawings provide us for the follow information

1. The specifications for the steel building do you need? (Length, width, and height, the height of the building can big affect the cost)

2. What is your steel building used for? (factory, workshop, warehouse, hangar, plant, poultry farm shed, etc.)

3. Thermal conditions of your steel building. (EPS, glass wool, rock wool, PU)

4. The lighting conditions of your steel building. (Ventilation/skylight)

5. The window and door requirements. (roll-up door/sliding door/steel door/ PVC door)

6. The wind-load/ snow load for your steel building. (to design a safe structure that can withstand the weather conditions)

7. Does The steel building have a crane or not? (3/5/10/15 ton)

8. Project location.

9. Surface treatment : Paint or hot dip galvanized.

10. how floors? Any mezzanine? or Other special demand.

If you are not about what type or what needs you have regarding you're warehouse/workshop, or this project is your first one. Don't worry, we will offer suggestion for you to choose the right style and the best design within your budget.

Why Choose Us?

1. Our people

Our engineers are very professional, and most of them have more than 10 years of experience in the architecture field.

Our work staff have steel structure processing excellent skills. Some of them even have overseas installation experience.

Our colleagues in the sales team are all passionate about their work and honest and humble towards our customers. Every inquiry or email will be replied to in time. Every question will be paid high attention.

2. Our service

We offer recommendations for our customers in the pre-sale stage.

We offer floor plans, elevation plans, and quotations for free.

We offer construction drawings, and calculation sheets to help you get a construction permit after the order is confirmed.

We offer detailed foundation and Installation drawings after delivery.

We offer details packing lists for every container when loaded so it will be easier to check and get the materials. Form A, Form E, and CO certificates are available.

3. Our advanced processing facilities

We possess more than 10 sets of large precise and domestically advanced processing equipment, including large gantry planing machines, automatic submerged arc welding machines, assembling machines, shot blasting machines, etc.