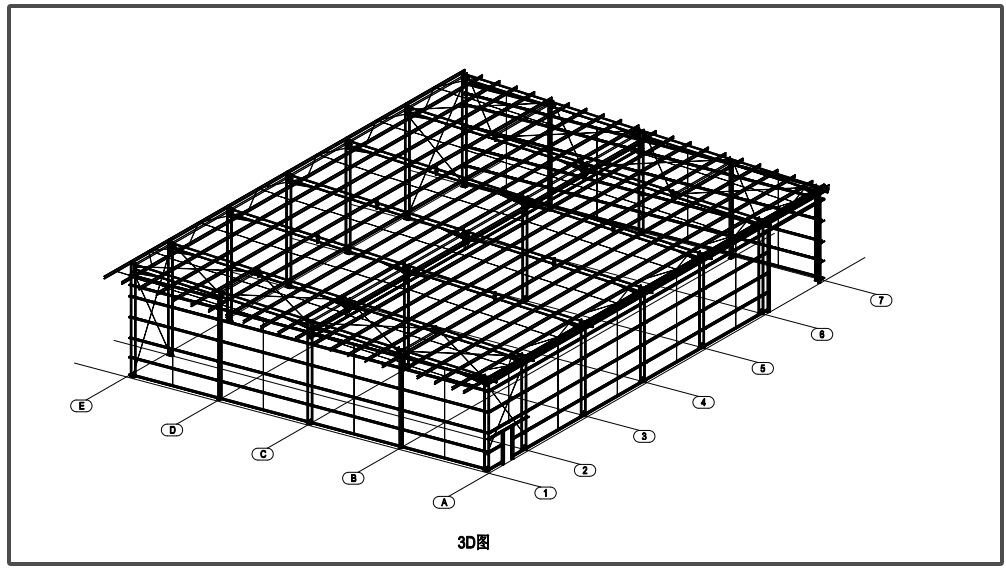

Clear-Span Structural Design for Unobstructed, High-Utilization Interiors

How Clear-Span Steel Framing Eliminates Interior Columns to Maximize Usable Square Footage

When using clear span steel framing, there are no interior columns at all which means completely open floor space throughout the building. Facilities that switch from traditional column supported designs typically gain between 15 to 30 percent more usable area. This extra space makes a big difference when setting up storage areas, placing equipment, or creating dedicated workflow sections. Material handling becomes much easier too since forklifts and those automated guided vehicles can move around freely without having to navigate around columns. Warehouse managers love how high density racking systems can stretch right from one wall to another, packing in more inventory while still keeping things visible for safety checks. According to facility operators across the country, loading operations speed up by about 20 percent in these column free spaces. Plus, buildings built this way adapt better to changing business requirements down the road without needing expensive structural modifications later on.

Clear-Span vs. Column-Supported Layouts: Performance Comparison in Industrial Steel Building Design

Clear-span structures consistently outperform traditional column-supported designs across core operational metrics:

| Performance Factor | Clear-Span Design | Column-Supported Design |

|---|---|---|

| Floor Space Utilization | 100% unobstructed area | 15–25% space loss from columns |

| Equipment Mobility | Unrestricted movement paths | Navigational challenges around columns |

| Storage Density | Optimized racking wall-to-wall | Reduced capacity due to column zones |

| Reconfiguration Ease | Simple layout changes | Structural constraints limit flexibility |

| Long-Term Value | Higher ROI via adaptability | Lower initial cost, higher lifetime adjustments |

Column-free designs reduce relocation and reconfiguration costs by 40% when scaling operations. Though requiring specialized engineering, clear-span systems deliver 18% lower lifetime maintenance costs than column-based alternatives. For warehouses, manufacturing plants, and aviation hangars—where revenue scales with usable space—this structural efficiency translates directly into competitive advantage.

Vertical Space Optimization in Steel Building Design

Mezzanine Integration: Structural Best Practices and ROI-Driven Design Protocols

Adding mezzanine floors represents one of those smart investments that deliver excellent returns when expanding vertically inside steel buildings. Getting the structural details right matters a lot. Engineers need to calculate both dead loads ranging from 50 to 100 pounds per square foot and whatever live loads will actually be placed on the platform. The connections between components should channel stress straight into main support columns instead of relying on secondary framing structures. Placement is another critical factor. Good design keeps these intermediate levels away from fire sprinklers, air conditioning ducts, and overhead cranes while still leaving at least seven feet of clearance for people moving around below. Compared to building out horizontally, installing a mezzanine costs roughly 40 to 60 percent less per square foot and usually doubles available floor space without changing the building's overall size. Many businesses find their operations run smoother too, reporting efficiency improvements between 25 and 35 percent after separating different functions like manufacturing areas, packaging stations, and administrative offices onto distinct levels. Most companies recoup their initial investment within 18 to 30 months simply by making better use of their existing space.

Overhead Storage and Wall-Mounted Systems as Cost-Effective Space-Saving Strategies

Storage systems installed overhead can turn wasted ceiling space into serious inventory real estate. These setups often use steel racks that hold around 2000 pounds per shelf, though specifics depend on what's being stored. Wall mounted options like cantilever racks and those modular panels along walls free up precious floor area. We've seen warehouses boost their storage capacity anywhere from 30 to almost half just by making better use of walls instead of expanding outward. The cost savings are impressive too. Most companies find these storage upgrades cost between 15 and 25 percent of what it would take to build out additional space. Plus, nobody wants higher property taxes because they expanded their footprint. When items are stored above ground level, workers have clearer paths to move around. Material handling times drop about 20 percent on average, which means fewer delays and less frustration. And there's something else worth mentioning: keeping things off the floor reduces tripping hazards. Safety reports consistently show workplaces with elevated storage systems experience fewer accidents related to cluttered floors.

Modular and Adaptable Layout Planning for Operational Flexibility

Workflow-Driven Modular Zoning in Pre-Engineered Steel Building Design

Modular zoning based on workflow turns steel buildings from just empty boxes into real workhorses for operations. When spaces get divided into specific areas for receiving goods, staging materials, processing items, and shipping out products, everything moves much smoother. Some smart layouts have actually cut down how far materials need to travel by around 40%. Steel buildings made with pre-engineered components offer something special here too. Their wide open spaces without columns and those standard connections make it easy to rearrange things when business needs change. Factories that switch to these U-shaped workflow setups often see production times drop between 15% and 20%, mainly because workers aren't running back and forth between stations so much anymore. The whole idea focuses on placing processes next to each other instead of sticking to rigid floor plans, which keeps operations flexible while still maintaining solid structural integrity.

Scalable Expansion Pathways: Integrating Future Growth into Initial Steel Building Design

Steel buildings designed with expansion in mind actually save money down the road by avoiding those expensive retrofit jobs nobody wants to deal with. The smart approach starts with reinforced foundations placed strategically where expansions might happen. Then there's the whole utilities thing - making sure power lines, data connections, and heating/cooling systems have access points that aren't buried somewhere impossible to reach. And let's not forget about those bolted connections between sections. When done right, these connections make adding new sections to an existing building almost as simple as putting together Lego blocks. Most facilities can grow their capacity by around 40% without shutting everything down for weeks on end. According to Facility Management Journal back in 2023, businesses that think ahead about expansion during the original design phase typically cut their future construction bills by about a quarter. Plus they maintain business continuity since steel naturally lends itself to this kind of modular growth over time rather than requiring complete overhauls.

FAQ

What is clear-span structural design?

Clear-span structural design refers to architectural planning where no interior columns obstruct the floor space, resulting in open and high-utilization interiors.

How does clear-span design improve space utilization?

By eliminating interior columns, clear-span design enables better use of the available area, increasing usable space typically by 15 to 30 percent.

What are the advantages of mezzanine floors in steel buildings?

Mezzanine floors enhance vertical space utilization, making operations smoother and more efficient, with costs typically 40 to 60 percent lower than horizontal expansion.

How do overhead storage systems benefit warehouses?

Overhead storage systems utilize ceiling space, freeing up floor area and significantly increasing storage capacity while reducing overall expansion costs.

What considerations are there for design flexibility in steel buildings?

Modular zoning and workflow-driven setups enhance operational flexibility, making it easy to adapt to changing business needs without significant structural adjustments.