Steel Grade: Q235B/Q355B (GB standard)

Application: Steel workshop

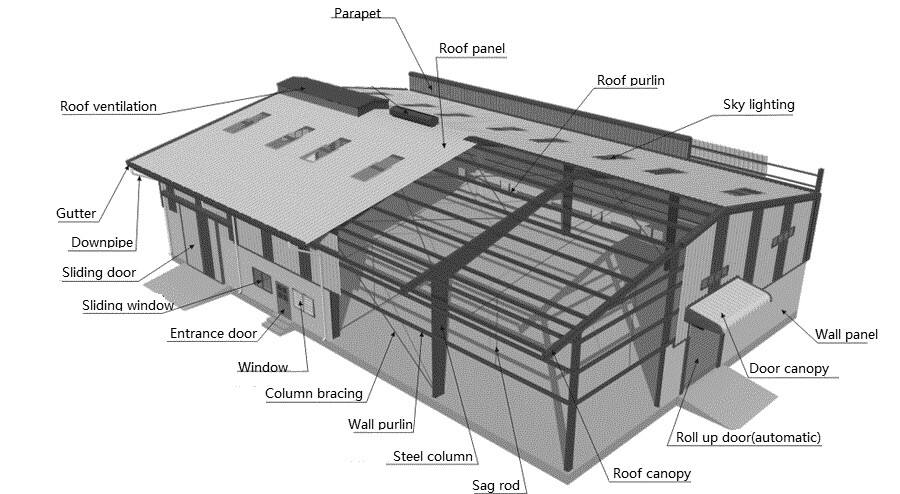

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

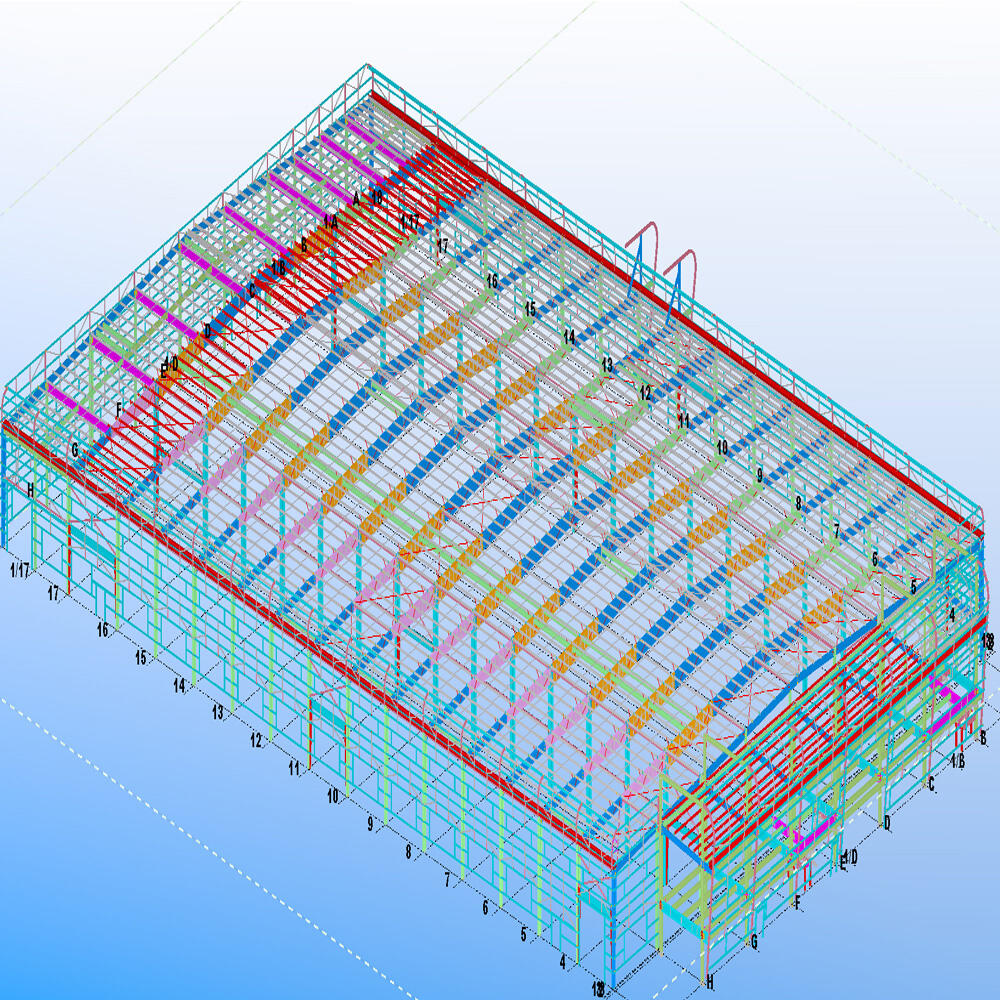

We offer custom-designed insulated steel workshops tailored to your specific requirements, whether you need a small unit or a large-scale facility. Our steel structures can be built with single or multiple spans, with a maximum span of up to 40 meters, and do not require central support columns, allowing for a wide, unobstructed interior space.

The featured steel workshop on this page covers an area of approximately 5,000 square meters per unit, with a total of 2 units totaling 10,000 square meters. The structure stands 14 meters high, offering ample vertical clearance for industrial operations.

This steel workshop is ideal for manufacturing, logistics, and storage operations that demand both functionality and energy efficiency.

On-Site Steel Workshop Installation

Steel Structure Workshop Installation Process

Installing a steel structure workshop involves several essential steps to ensure a durable and efficient building. Our detailed installation guide includes:

Step 1: Foundation Preparation

The first step is preparing the construction site and laying a strong, stable foundation. A properly prepared foundation is crucial for the overall strength and longevity of the steel workshop.

Step 2: Installing Main Frames and Purlins

After the foundation is ready, the main structural frames and purlins are assembled. Main frames act as the building’s primary support, while purlins provide additional reinforcement for the roof and walls.

Step 3: Wall Cladding Installation

Once the frames are in place, metal wall panels are securely attached to the framework, forming the exterior walls of the workshop. This cladding offers protection and durability.

Step 4: Roof Cladding Installation

Following wall installation, metal roof panels are fixed onto the roof framework, creating a weatherproof and sturdy roof system that protects against harsh environmental conditions.

Step 5: Finishing Trimming

The final step includes installing trim components such as flashing, gutters, and ridge caps. These finishing touches ensure proper sealing, prevent water leakage, and give the workshop a clean, professional appearance.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

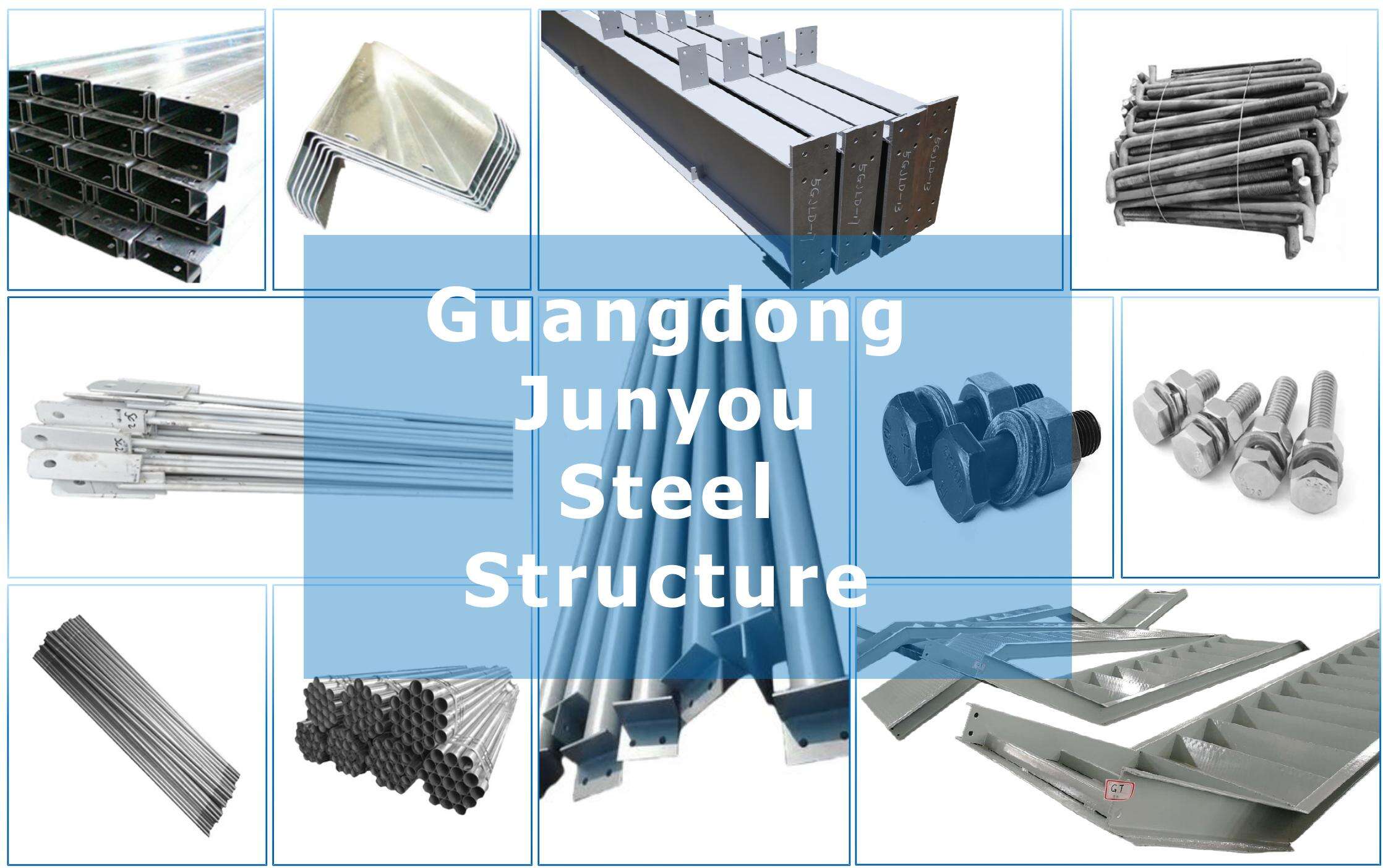

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Steel structure building application

It has various applications in construction, including commercial buildings, warehouses, workshops, storage sheds, aircraft hangars, industrial facilities, agricultural structures, poultry farms, chicken houses, barn sheds, sports arenas, and residential buildings, etc. Steel's versatility allows it to be used in a wide range of projects, providing strength and durability in different settings.

Top 5 Advantages of Steel Structure Workshops

● Fast Installation

All components are prefabricated and precisely cut, allowing for quick on-site assembly. This saves time, reduces labor, and lowers construction costs.

● Flexible Design

Steel workshops are easily expandable or modifiable. They can be connected to existing buildings or adjusted as your business grows.

● Cost-Effective & Eco-Friendly

Steel is recyclable, durable, and energy-efficient. It reduces both construction time and long-term maintenance costs.

● Weather & Fire Resistant

Steel structures are designed to withstand wind, snow, earthquakes, and fire—ensuring safety and durability in any climate.

● Low Maintenance

Steel resists rust, pests, and warping. It requires minimal upkeep, making it a smart long-term investment.

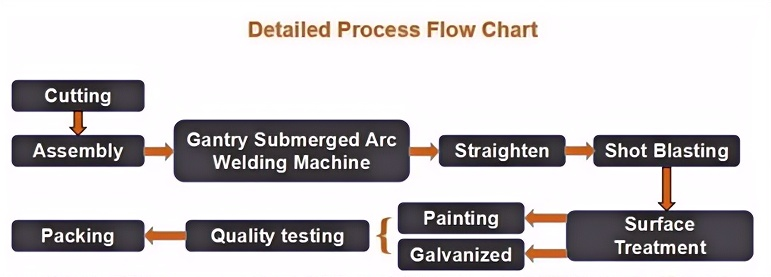

Steel Workshop Fabrication Process:

Get Your Tailored Steel Workshop Quote Today! - Faster Build, Lower Costs, Sustainable Results!

E-mail: [email protected]

Phone: +86-13535848691