Steel Grade : Q235B/Q355B (GB standard)

Application: Steel Warehouse

Steel Frame: Portal Frame Steel System

Purlin: C/Z Galvanized Steel

Connection Form: Bolt Connection

Life span: 50 Years

Delivery Time: 25~30 days

Place of Origin: Foshan, Guangdong, China

MOQ: 200 Sqmt

Today's top-performing warehouses utilize high-strength steel structures, offering unmatched durability for industrial and commercial storage needs. These steel and metal warehouse buildings provide:

✔ Superior strength to safely store heavy goods

✔ Weather-resistant protection against natural elements

✔ Long-lasting construction that endures for decades

✔ Customizable features including:

Engineered for efficiency, these prefabricated steel warehouses deliver optimal storage capacity while requiring minimal maintenance. Their modular design allows for future expansion as your business grows.

On-Site Steel warehouse Installation

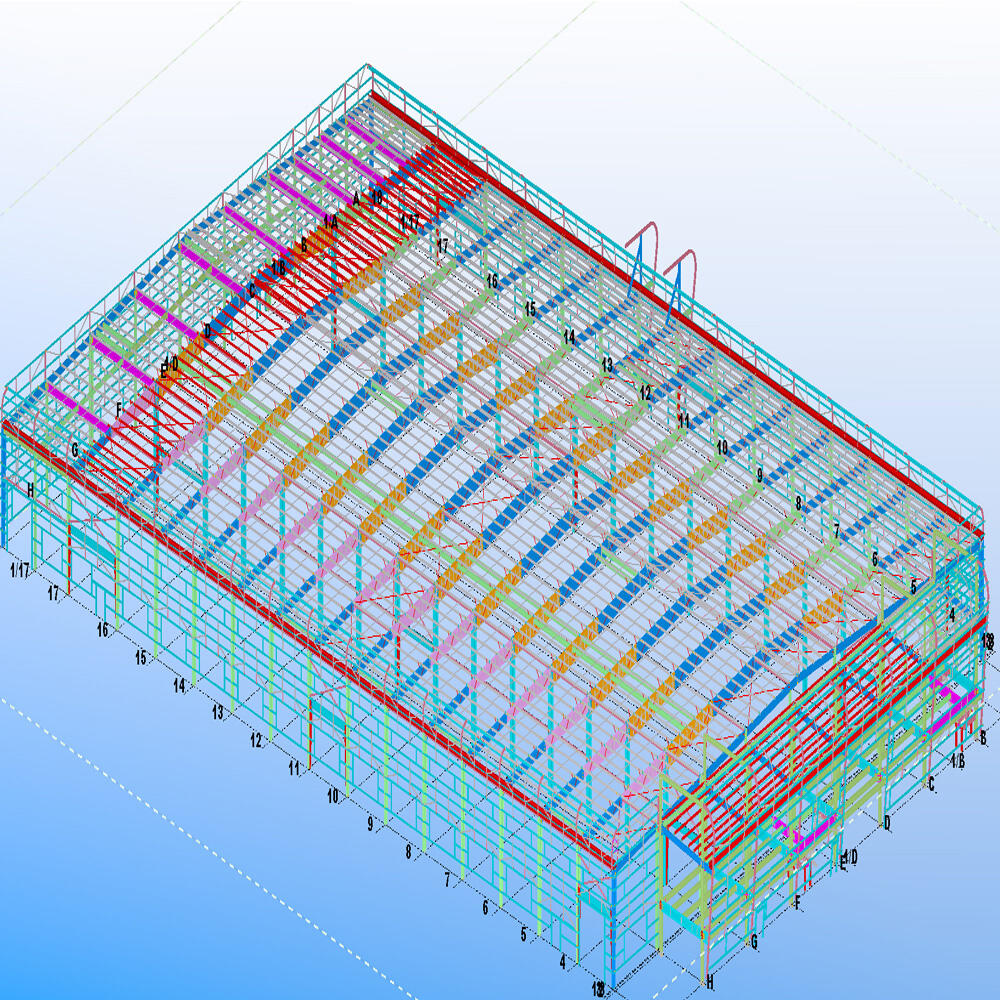

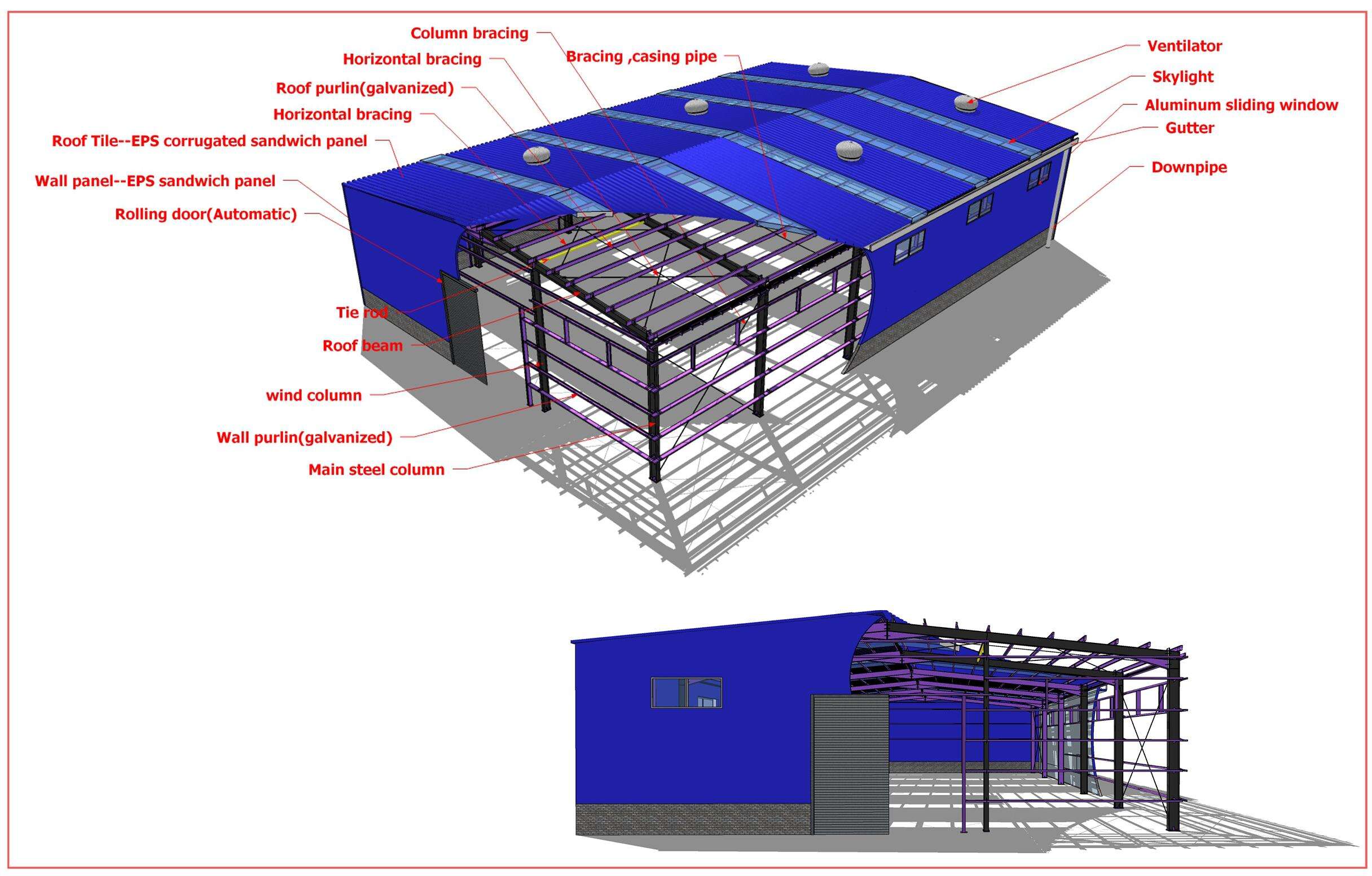

3D Steel Structure Warehouse Model Material Display

4 Types of Steel Frame Structures for Warehouse Construction

Among them, the most widely used are the basic building frame structure and the portal rigid frame, both known for their efficiency and cost-effectiveness.

These steel warehouse frame systems offer excellent strength, stability, and durability, making them ideal for various construction applications, including industrial warehouses, storage facilities, and logistics centers.

By selecting the right structural type, your steel warehouse can meet specific load requirements, span widths, and functionality needs, ensuring long-term performance and structural integrity.

Technical Specifications

I |

Main steel frame |

|||

1. |

Steel structure frame |

Welded H steel/H section |

Q235B/Q355B |

Painting/Hot-dip galvanized |

2. |

Wall/Roof purlin |

C/Z steel |

Q235B |

Galvanized |

II |

Bracing Part |

|||

1. |

Tie Rod |

∅89/114/158 |

Q235B |

Painting/Hot-dip galvanized |

2. |

Flexible Bracing |

∅16/18/20 |

Q235B |

Painting/Hot-dip galvanized |

3. |

Bracing |

∅20 |

Q235B |

Galvanized |

4. |

Rod brace |

∅32 |

Q235B |

Galvanized |

5. |

Knee-brace |

L50 |

Q235B |

Painting/Hot-dip galvanized |

III |

Roof & Wall Part |

|||

1. |

Roof /Wall panel |

Steel sheet |

0.326~0.7mm corrugated steel sheet |

|

Insulated sandwich panel |

EPS,Glass wool/Rock wool/PU/PIR insulated |

|||

2. |

Roof/Wall trimming |

Ridge roof panel |

0.4~0.7 mm steel sheet |

|

Flashing |

0.4~0.7 mm steel sheet |

|||

Gable wall trimming |

0.4~0.7 mm steel sheet |

|||

Wall corner trimming |

0.4~0.7 mm steel sheet |

|||

IV |

Window & Door part |

|||

1. |

Window |

PVC/Aluminum frame |

Single/double glazing (Fixed/sliding/swing) |

|

2. |

Door |

Rolling/sliding door |

Automatic and manual method |

|

V |

Accessories |

|||

1. |

Bolts |

Anchor bolts,High strength bolts,Galvanized bolts,Turnbuckle,shear stud |

||

2. |

Gutter |

Steel sheet/galvanized/Stainless steel(304) |

||

3. |

Downpipe |

PVC 110/160 |

||

4. |

Roof Ventilator |

∅600 (Galvanized) |

||

Rolling Door vs. Sliding Door for Steel Warehouses

When choosing a warehouse door, two common options are the rolling door and the sliding door, each offering different advantages based on usage needs.

Rolling doors, also known as electric rolling gates, operate by rolling vertically up and down along metal tracks. They are typically made of connected steel slats or metal panels, providing excellent security and weather resistance. These doors are widely used in industrial warehouses and can be operated either manually or automatically with an electric motor for greater convenience.

Sliding doors, on the other hand, move horizontally along tracks and are made from large steel or metal panels. This type of door is ideal for warehouse buildings requiring wide, unobstructed access. Sliding doors are valued for their durability, smooth operation, and ability to accommodate large openings with minimal maintenance.

Applications of Steel Warehouse Buildings

Steel structure warehouses are widely used across various sectors due to their strength, durability, and fast installation. These versatile buildings are ideal for both domestic and international markets, offering long-term performance with low maintenance.

Common applications include:

Advantages of Prefabricated Steel Warehouses

High-strength steel ensures long-lasting performance in industrial environments.

All parts are prefabricated, reducing on-site labor and speeding up construction.

Spacious interiors and wide entryways improve logistics and workflow efficiency.

Low construction waste, water-saving, and recyclable materials make it sustainable.

Heat-resistant panels provide safety and stable indoor temperatures.

Steel Warehouse Fabrication Process:

Steel structure building/workshop/warehouse/Godown Design information we need:

1. The specifications for the steel building do you need? (Length, width, and height, the height of the building can big affect the cost)

2. What is your steel building used for? (factory, workshop, warehouse, hangar, plant, poultry farm shed, etc.)

3. Thermal conditions of your steel building. (EPS, glass wool, rock wool, PU)

4. The lighting conditions of your steel building. (Ventilation/skylight)

5. The window and door requirements. (roll-up door/sliding door/steel door/ PVC door)

6. The wind-load/ snow load for your steel building. (to design a safe structure that can withstand the weather conditions)

7. Does The steel building have a crane or not? (3/5/10/15 ton)

8. Project location.

9. Surface treatment: Paint or hot dip galvanized.

10. how floors? Any mezzanine? or Other special demand.

Contact Us to Start Your Project

Ready to build a durable and cost-effective prefabricated steel warehouse? Our expert team is ready to provide you with a customized solution—from initial design and fabrication to on-site installation and after-sales support.

E-mail: [email protected]

Phone: +86-13535848691