Technical Parameters: Size (L) 61m x(W) 27 m x(H) 20.6m Area 3294 square meters Wind resistance 110km/h Anti-seismic 7 grade Roof dead load 0.25KN/m² Roof live load 0.3KN/m² Project info. This project is a wo...

Technical Parameters:

| Size | (L) 61m x(W) 27 m x(H) 20.6m |

| Area | 3294 square meters |

| Wind resistance | 110km/h |

| Anti-seismic | 7 grade |

| Roof dead load | 0.25KN/m² |

| Roof live load | 0.3KN/m² |

Project info.

This project is a workshop for a chemical workshop(plant), used to store chemical coatings. The company mainly produces water-based acrylic emulsions, coating adhesives, and resin-based products.

Although the structure has only two floors, the floor load capacity reaches 1500kg/m². The largest floor beam size is H1650×500×28×30mm, and the total steel weight is about 400 tons. We completed the material fabrication within one month and delivered it to the client on schedule.

The materials were delivered to the construction site in batches. With bolted connections and precisely pre-drilled holes, the installation process was significantly accelerated, allowing the facility to be put into operation quickly. The client expressed strong confidence in our products.

We believe as an chemical workshop, it must meet the below conditions:

● High Structural Strength and Load Capacity

The steel framework must support heavy equipment, storage tanks, and dynamic industrial loads.

● Corrosion Resistance

Materials and protective coatings (epoxy zinc-rich primer and alkyd paint) are essential to resist chemical exposure and harsh environments.

● Fire Protection Measures

Fire-resistant coatings or cladding, firewalls, and proper spacing between structural elements help meet safety codes in hazardous settings.

● Efficient Ventilation and Exhaust Systems

Proper air circulation and chemical fume extraction systems ensure safe working conditions.

● Fast and Precise Assembly

Prefabricated steel components with bolted connections allow for rapid on-site installation and reduced construction time.

● Maintenance Accessibility

The structural design should allow for easy access to equipment for maintenance, inspection, and upgrades.

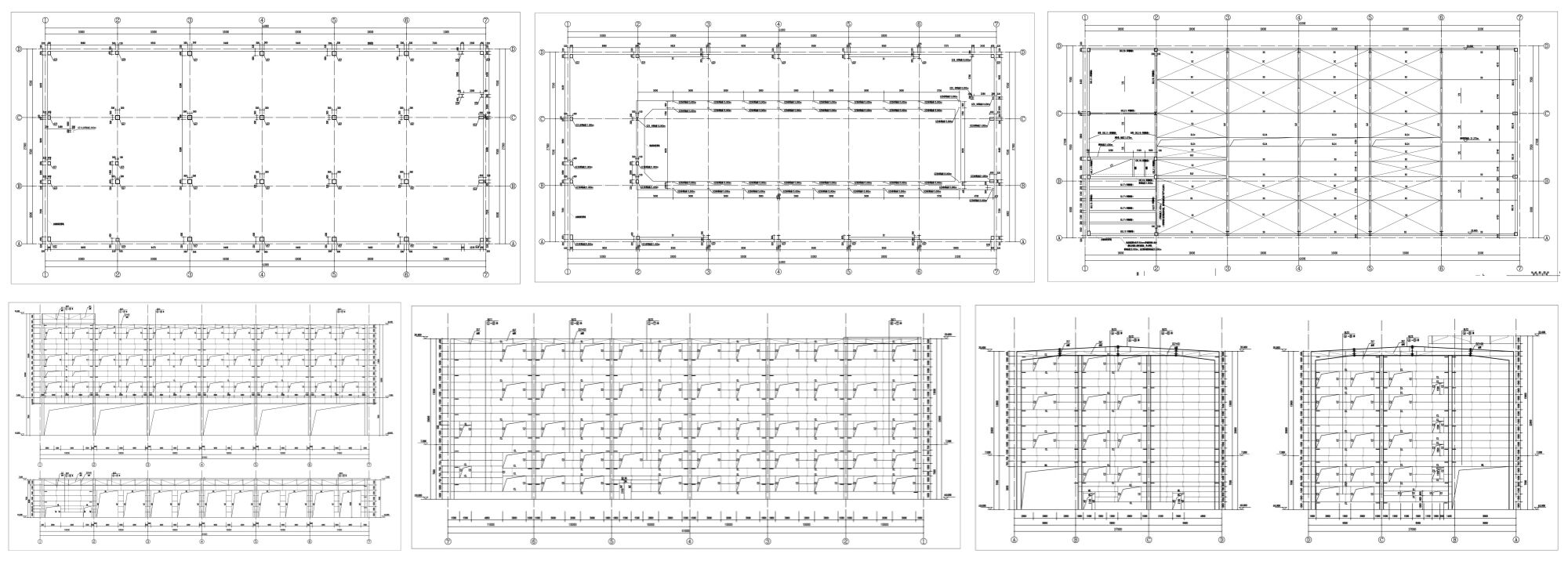

The drawing of the whole steel building

Valuable customer steel structure building feedback

● During our inspection visits to the factory, we observed that all production processes were conducted in strict accordance with industry standards and relevant specifications. The quality of the steel structure—both in terms of materials and dimensional accuracy—fully met the requirements outlined in the contract. We are highly satisfied with the consistency and reliability of the fabrication work.

● The manufacturer provided detailed planning for the packing and transportation of all steel components. They accurately calculated the container space, which significantly helped us reduce logistics costs and avoid material damage during shipping.

● The installation manuals provided were clear, detailed, and easy to follow. As a result, our on-site construction team was able to carry out the installation process smoothly and efficiently, with minimal technical issues.

Photos from Completed Projects