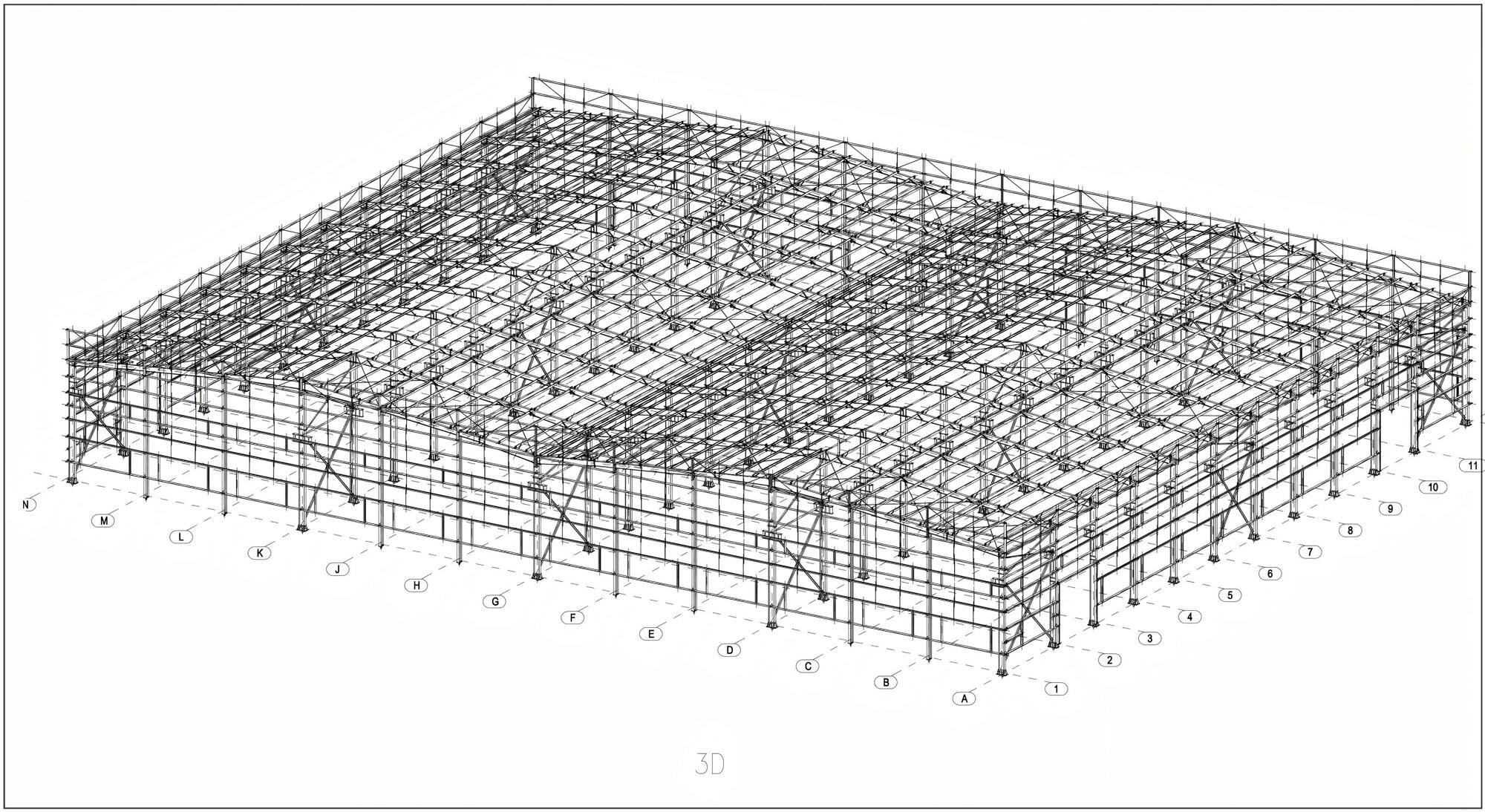

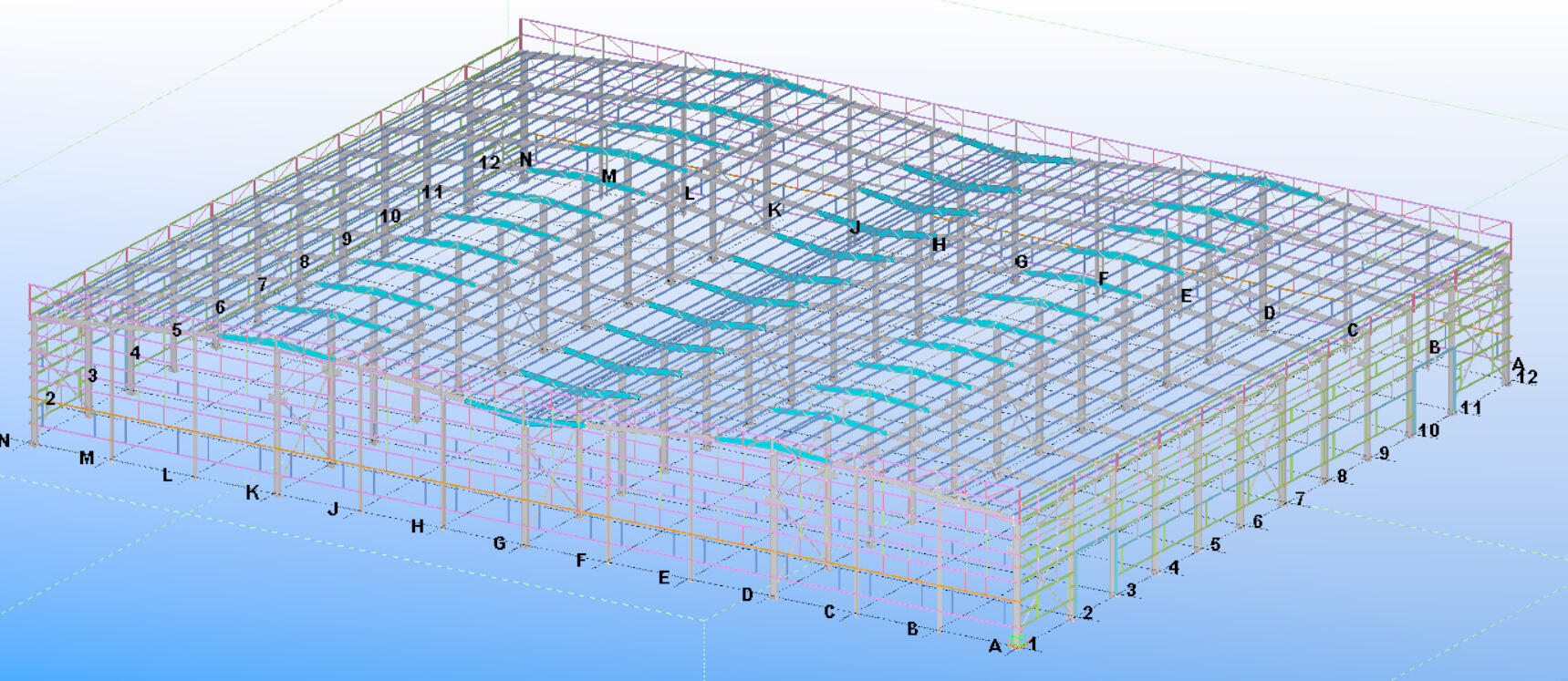

Technical Parameters: Size (L) 78m x(W) 66 m x(H) 9m Area 5148 square meters Wind resistance 110km/h Anti-seismic 7 grade Roof dead load 0.25KN/m² Roof live load 0.3KN/m² Project info. This is our secon...

Technical Parameters:

| Size | (L) 78m x(W) 66 m x(H) 9m |

| Area | 5148 square meters |

| Wind resistance | 110km/h |

| Anti-seismic | 7 grade |

| Roof dead load | 0.25KN/m² |

| Roof live load | 0.3KN/m² |

Project info.

This is our second project for automotive processing and manufacturing workshop and storage recently.

We believe as an automobile processing and production workshop, it must meet the below conditions:

Steel structure frame surface treatment: (3 methods)

1) Spray paint: epoxy zinc-rich primer and alkyd topcoat.

2) Hot-dip galvanizing: pickling and then galvanizing, generally 80~180 microns.

3) Fire retardant coatings are sprayed on site: epoxy zinc-rich primer and epoxy cloud iron middle paint.

Each method has its own characteristics, and customers can choose the solution that suits them according to their needs and budget.

Our client chose the 3rd method because there are relatively expensive machines and intensive workers working in the workshop, so safety is the most important thing.

Before applying fireproof coating on the steel structure, the surface of the steel frame should be treated with anti-corrosion. It is recommended to use epoxy-rich zinc anti-corrosion primer and epoxy cloud iron for intermediate paint. The anti-corrosion primer must be dry before applying the fireproof coating. It is important to note that if the fireproof coating is needed, there is no need to use a finished coat because topcoat and fireproof coating are not compatible. This means that if topcoat is applied before fireproof coating, the fireproof coating will not adhere to the surface of the steel structure and will not achieve the fireproof effect.

The beauty of the entire steel structure

Valuable customer steel structure building feedback

1)When we made inspections at the factory, we could see that the factory operated according to relevant production processes and specifications, ensuring the quality and dimensional accuracy of the components. The quality of the steel structure, whether it was the material or dimensions, they are all complied with the requirements specified in the contract, and we are very satisfied with this.

2)The factory has made detailed plans and operations for the transportation of the components, accurately calculating the container volume, which help us to save costs.

3)The installation instructions are clear, allowing construction personnel to proceed with the installation smoothly.