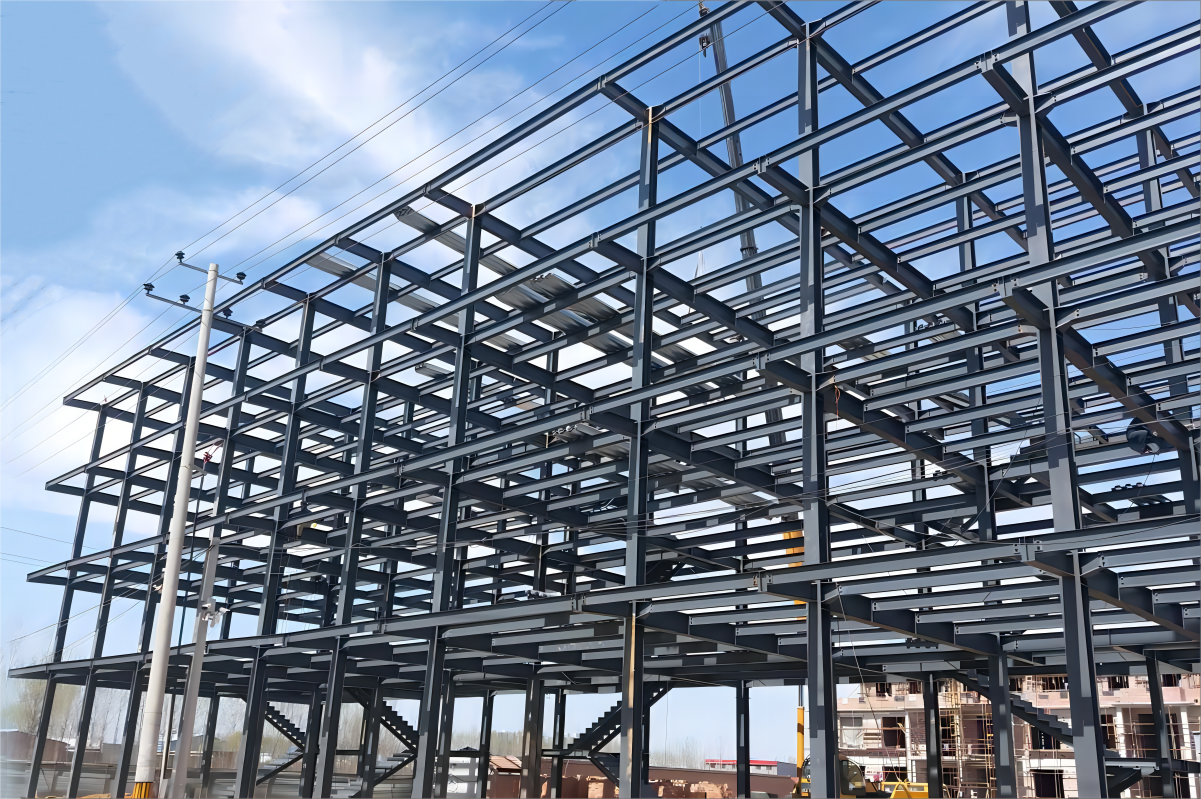

Steel building construction by Guangdong Junyou Steel Structure Co., Ltd. is a sophisticated, efficient process that combines advanced engineering with precision manufacturing to deliver high-quality, durable structures. The process starts with collaborative design, where engineers work closely with clients to understand functional requirements, site conditions, and budget constraints, developing detailed plans that optimize strength, space, and cost. High-quality steel—selected for its strength, ductility, and weldability—is then used to fabricate structural components (beams, columns, trusses) in the factory, using CNC cutting, bending, and welding equipment to ensure exact dimensions and structural integrity. These prefabricated components are transported to the site, where the construction team begins by installing the foundation, followed by erecting the steel frame. The frame is assembled using high-strength bolts or welding, creating a rigid structure capable of withstanding loads and environmental forces. Once the frame is complete, secondary components (purlins, girts) are added to support wall and roof cladding, which can be metal, glass, or other materials based on design needs. Utilities (electrical, plumbing) are integrated during construction, along with insulation if required. Throughout the process, quality control inspections verify material quality, weld integrity, and structural alignment, ensuring compliance with building codes and safety standards. Steel building construction reduces on-site construction time, minimizes waste, and offers superior durability compared to traditional methods, resulting in a structure that is strong, flexible, and built to last.